No More Blind Hunts: Bird Dog Leak Detector Leads You Straight to the Leak

Bird Dog Leak Detector saves the day

If you’ve ever chased a leak that “shouldn’t” exist, you know small problems can become big headaches. That’s why we make Bird Dog Leak Detector in two formulas—Regular and Low-Temp. Both create fast, tight bubbles that point to leaks you can’t see or hear. Low-Temp is built for cold weather and cold systems, so it keeps working when other products don’t.

The email that started it:

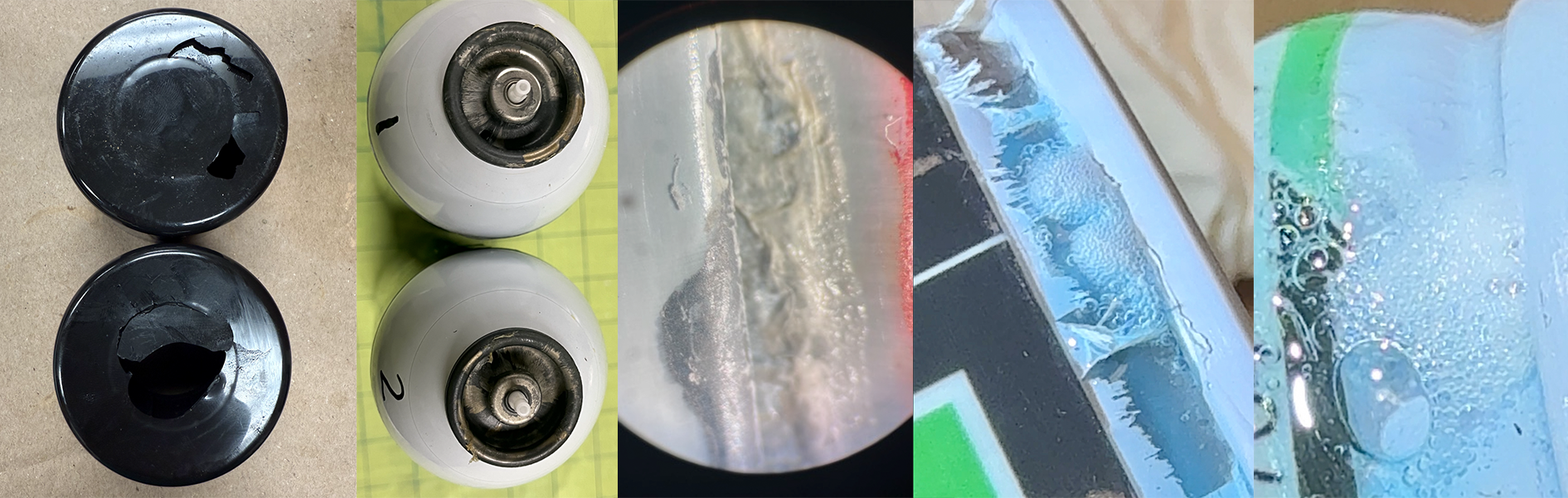

A customer sent photos: damp cartons and residue on aerosol cans in their warehouse. They suspected seam failures and wanted confirmation before this turned into a broader issue. We requested samples to investigate and let them know we’d involve the can supplier for definitive testing.

For context: we buy around 50,000+ aerosol cans at a time (a full truckload). When we run this product in particular, we run batches of 3,600–6,000 cans and there is 1,200 cans per completed pallet. From that production lot, product was shipped all over the country and we still had inventory sitting in our own warehouse. Only one pallet showed leaking issues.

We sent cans to the supplier for a full evaluation:

- Pressurized and submerged the cans in a water bath to watch for bubbles.

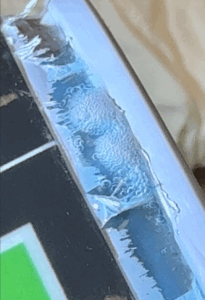

- Cut open units to inspect for internal corrosion or trace leak paths.

- Put the bottom seam under a microscope and documented the seam profile.

Result: no leaks detected, no internal corrosion, no visible seam defects. On paper, everything was perfect. Because if the lab didn’t find it, it must not exist… right?

The problem didn’t go away

The customer wasn’t imagining things. A couple week later we asked them to ship back more cans, they shipped back about 50 more cans they believed were leaking at the bottom seam. This time, we ran an extended in-house evaluation designed to catch what submersion tests and microscope snapshots couldn’t find.

Our in-house evaluation

- We cleaned, dried, and weighed each can.

- We placed them upright on clean white paper, undisturbed, overnight at ~74°F.

- We rechecked the paper and weight after roughly 14 hours.

What we saw: faint wet rings under a subset of units. What we measured: weight losses ranging from about 0.03 grams up to around 1.0 grams in 14 hours. That’s tiny—but real. A micro-leak was present. Now we needed the exact point of failure.

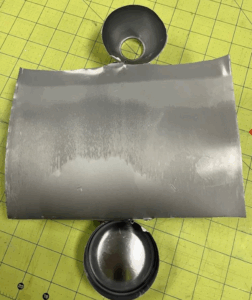

Bird Dog Leak Detector goes to work

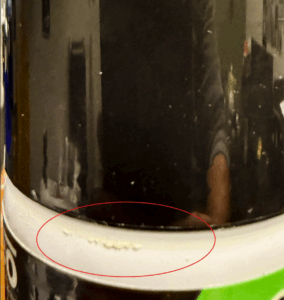

We reached for our Bird Dog Leak Detector. We brushed a thin, even film around the suspect seam area and watched. Within seconds, tiny, sustained bubbles formed along a specific stretch of the seam—repeatable, photographable proof of a leak that immersion testing and pressure testing had missed. Orientation and surface tension matter with micro-leaks; what doesn’t show in a bath can reveal itself immediately when a proven bubble-forming detector is applied with the can in a real-world position.

How small is “micro”? Here’s the reality check

Each can carries a net weight of 510 grams and is labeled 20 fl oz (≈591.5 mL). At room temperature, that corresponds to an average density of roughly 0.86 g/mL.

From our overnight checks:

- 0.03 g in 14 hours ≈ 0.0514 g/day. At that rate, emptying 510 g would take roughly 9,923 days (~27 years).

- 0.5 g in 14 hours would be roughly 1,000 days to empty 510 g: 1,020 days (~2.8 years).

- Translation: less than a drop roughly every 12 hours. You’re not going to hear it and you probably won’t see it….unless you used Bird Dog.

This is exactly why micro-leak detectors were invented and used particularly in plumbing and HVAC applications where tiny leaks can cost lots of money. Finding the leak was half the battle. Understanding the “why” was the other half. Closer inspection revealed:

Root cause: not a seam failure—handling damage.

- Slightly damaged or stretched caps on multiple cans.

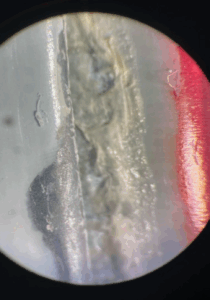

- Dried product ring under the caps.

- Indication of minor corrosion present on top cup of multiple cans.

- Tops of labels wet and beginning to discolor and peel away from aerosol can.

The most likely scenario became obvious. During transit or storage, something heavy was stacked on top of one pallet of aerosols. That weight depressed the actuators beneath the caps, releasing product under the cap. When the weight came off, the caps rebounded, releasing residual product that migrated down the labels and collected at the bottom seam. Over time, that external residue at the seam area contributed to tiny, intermittent leaks—leaks from the outside in. Not a manufacturing seam defect. Had it been a manufacturing defect, we would have likely seen leaking across additional dozens of products we manufacture using the same can, no such leaking present.

Remember the scale: we buy around 50,000+ cans per truckload and run this product in batches of 3,000–5,000 cans at a time. Product from this lot went nationwide and sat in our warehouse too. Only one pallet showed the problem. That’s not a process failure; that’s a handling event.

Operational takeaways you can use today

- Don’t stack heavy loads on pallets of aerosols. Even brief compression can depress actuators and set up slow-motion micro-leaks.

- Match the formula to your environment. If you run winter routes or store stock in unheated spaces, Bird Dog Low-Temp avoids downtime and repeat trips.

- Document with confidence. Persistent bubble trails photograph and video beautifully—ideal for supplier discussions, QA documentation, and customer communication.

- Double and even triple check product when it arrives to your facility, things happen in transit out of our control and sometimes things show up damaged but we can’t file a claim if they’re not closely inspected and marked as such.

- We also wrap our outbound in colored shrink wrap to help identify pallets that may have been re-stacked or damaged during transit. If it shows up in clean shrink wrap, it didn’t leave our facility that way.

- If it can find that leak, it can absolutely find a leak in your installs or service checks.

Why teams choose Bird Dog Leak Detector

- High sensitivity: tight, persistent bubbles at ultra-low flow—no guesswork.

- Fast visualization: see bubbles in seconds and pinpoint the exact location.

- Two formulas, one standard: Regular for everyday work; Low-Temp for cold climates and overnight truck storage.

- Versatile: effective on threaded joints, seams, valves, fittings, coils, and assemblies across HVAC/R, industrial, and MRO applications.

- Safe on all refrigerants and even oxygen applications.

- Confidence you can show: bubbles provide photographic and video proof you can share with suppliers, QA teams, and customers.

For the record, we also tried the regular hand soap and water mixture. It flagged the obvious, fast rate leakers —but it completely missed the slow, orientation‑sensitive micro‑leaks we documented. The soap film just doesn’t have the tension, film strength, or bubble stability needed for ultra‑low flow rates. Bird Dog Leak Detector did: it clung, formed tight, persistent bubbles, and revealed what the soap-and-water bubble test could not. That’s the difference between a handy hack and a purpose‑built micro‑leak detection tool.

Unfortunately, we couldn’t provide a refund for our customer, damage in transit is out of our hands, but we did provide them new boxes and labels for the product that was undamaged and shipped them replacements so they weren’t out of product.

Click here to see the leaks, damaged product and watch bird dog being made.

- Photos of the seam leak as Bird Dog reveals the bubble trail.

- A close-up of the dried ring under the cap that pointed to handling damage.

- Inside the leaking cans, no rust or visible damage present.

- A behind-the-scenes look at Bird Dog being filled.

Links:

Other Leak Detectors:

Technical & Industry Resources

Consumer Aerosol Products Council (CAPCO): <a href=”https://www.aerosolproducts.org/” target=”_blank” rel=”noopener”>Aerosol Products – Consumer Aerosol Products Council</a>

OSHA: <a href=”https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.101” target=”_blank” rel=”noopener”>Compressed gases (general requirements) | Occupational Safety and Health Administration</a>

EPA: <a href=”https://www.epa.gov/section608/section-608-technician-certification-0” target=”_blank” rel=”noopener”>Section 608 Technician Certification | US EPA</a>

BYJU’S: <a href=”https://byjus.com/chemistry/viscosity-and-surface-tension/” target=”_blank” rel=”noopener”>Viscosity And Surface Tension – BYJU’S</a>