Glycol Inhibitor: Essential pH Management for Hydronic Systems

Maintaining a hydronic system’s health is crucial for efficiency and longevity. If your setup requires freeze protection, inhibited glycol is necessary. However, glycol performance depends entirely on proper water chemistry. Monitoring system pH, among other things like the glycol percentage and inhibitor levels, allows you to catch issues before they arise.

A quality Glycol Inhibitor is the key to reliable, efficient, and long-lasting operation when maintaining your Vapco glycol-filled system.

⚠️ Important Compatibility Note: The Vapco Glycol Inhibitor is specifically designed to work with Vapco inhibited glycol products. Do not mix with other brands or chemistries.

⚠️ Raw Glycol (especially when heated and diluted with water) is inherently corrosive, that’s why most glycol is sold pre-inhibited. The inhibitor package and the glycol itself, does wear out over time, a process that is accelerated by heat and oxygen.

Why a Glycol Inhibitor is Necessary

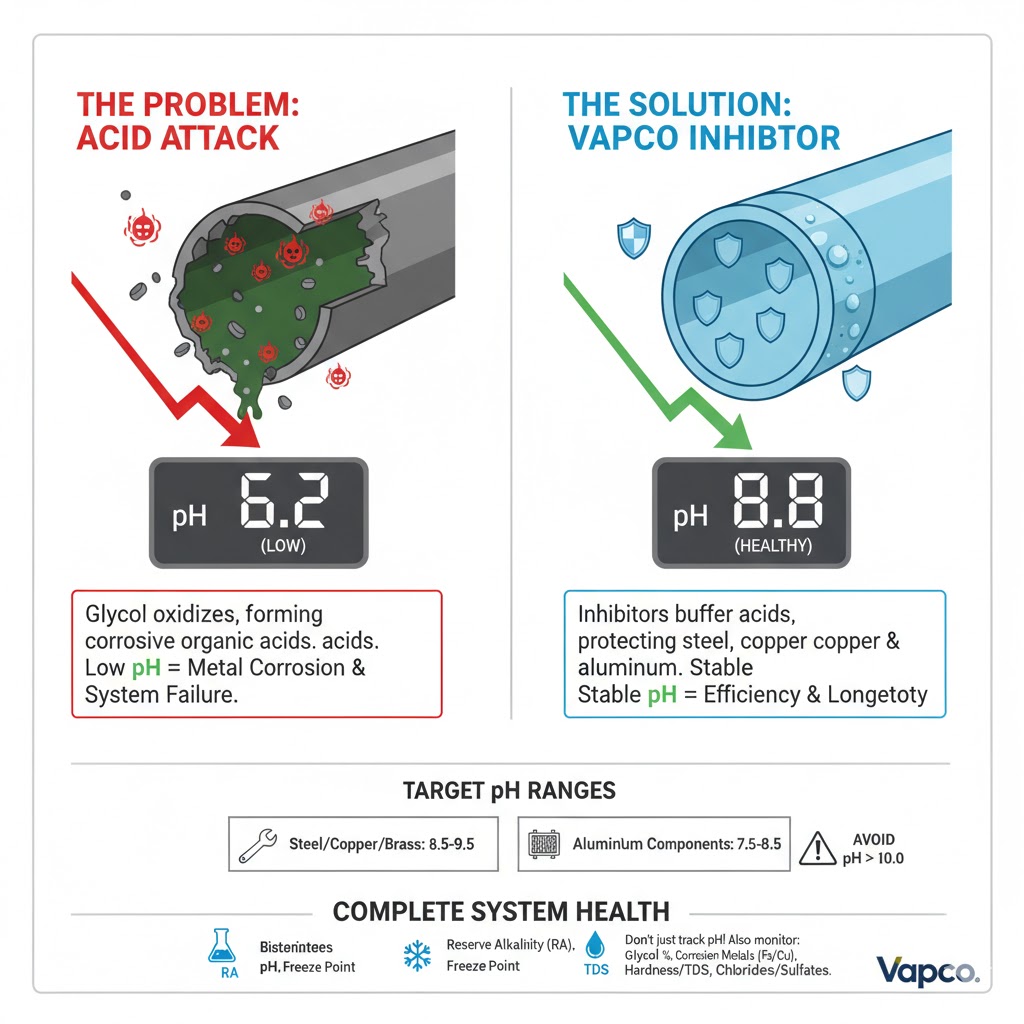

System fluid pH is the most useful routine check you can perform. This value indicates whether the inhibitor package remains healthy, where it can continue to buffer and protect metals against corrosion. Glycol slowly oxidizes over time, which forms corrosive organic acids. These organic acids begin consuming the system’s original inhibitor reserve, where a trending drop in pH signals inhibitor depletion/consumption. Consequently, an acidic environment rapidly accelerates corrosion of metal components.

Protecting your Investment

Inhibitors buffer those organic acids, protecting your expensive metal components. If the inhibitors are depleted, the fluid turns acidic, leading to corrosion and eventually, larger problems. Proactive pH monitoring is therefore critical. Using a glycol inhibitor helps prevent this costly outcome and maintains the integrity of your glycol investment, in conjunction with properly monitoring the system, this is not a “pour it and forget it” scenario.

Understanding Target pH Levels

The correct pH range depends significantly on the metals in your system. Always consult your equipment OEM’s limits first. Following these general guidelines are to give an understanding, not replace the manual.

The pH Range is System Specific

| System Metallurgy | Recommended pH Range | Key Consideration |

| Steel, Copper, Brass | Typically 8.5–9.5 | Avoid high alkalinity (>10.0). |

| Aluminum Components | Typically 7.5–8.5 | Many OEM’s prefer 8.0–8.5. |

Avoid allowing the pH to rise above 10.0. Some equipment manufacturers limit the maximum to 9.5 for safety. Furthermore, pH is only one metric. You must also track Reserve Alkalinity (RA – which measures the inhibitor’s remaining buffer capacity), as well as the glycol percentage, iron/copper (corrosion), hardness/TDS, chlorides, and sulfates.

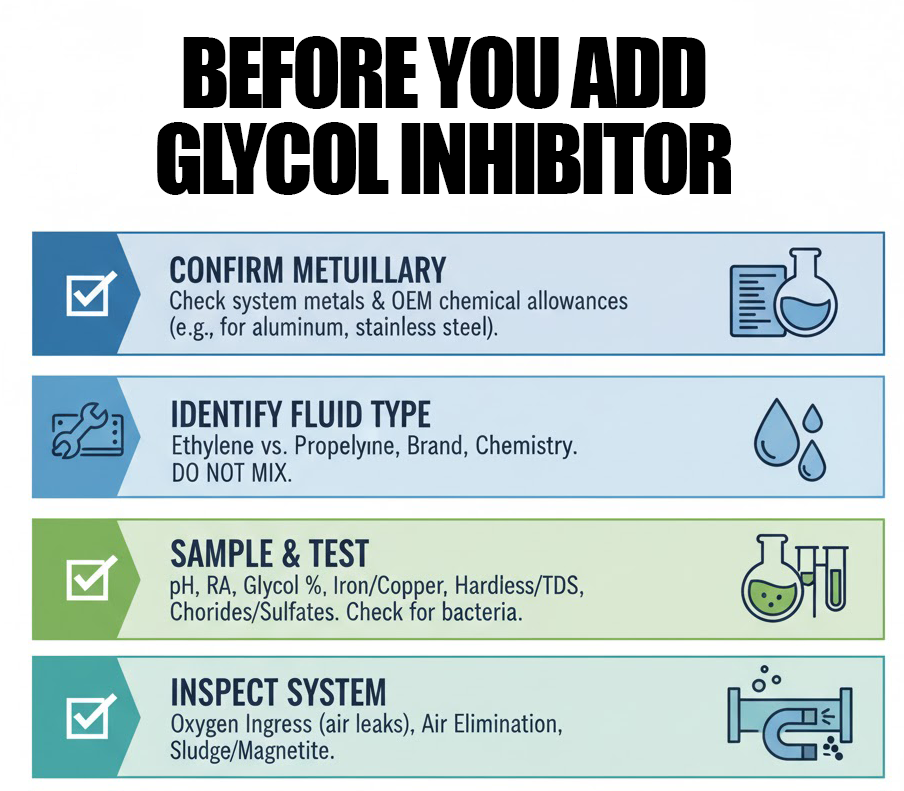

Pre-Dosing Checklist: Before Adding Glycol Inhibitor

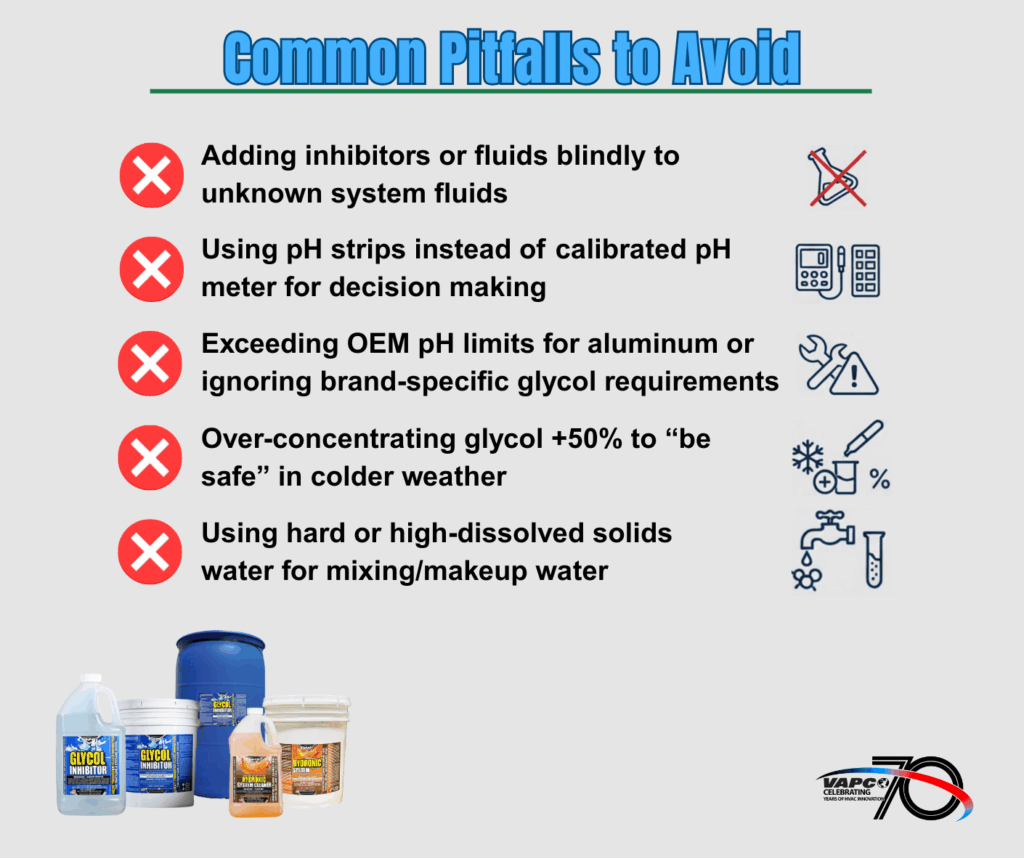

Before attempting fluid correction, you must perform a quick audit. This step prevents potential damage from incompatible chemical mixtures. It also ensures you understand the system’s current state.

Essential Audit Steps

- Confirm Metallurgy: Identify system metals and check OEM chemical allowances.

- Confirm Vapco Fluid: Verify the system contains Vapco inhibited glycol to ensure compatibility with our booster.

- Sample and Test: You should use a calibrated meter, not pH strips, to make decisions. Test pH, RA, glycol percentage (freeze point), and key contaminants.

- Inspect System: Check for air leaks and oxygen ingress. Verify air elimination effectiveness. Look for signs of sludge or magnetite.

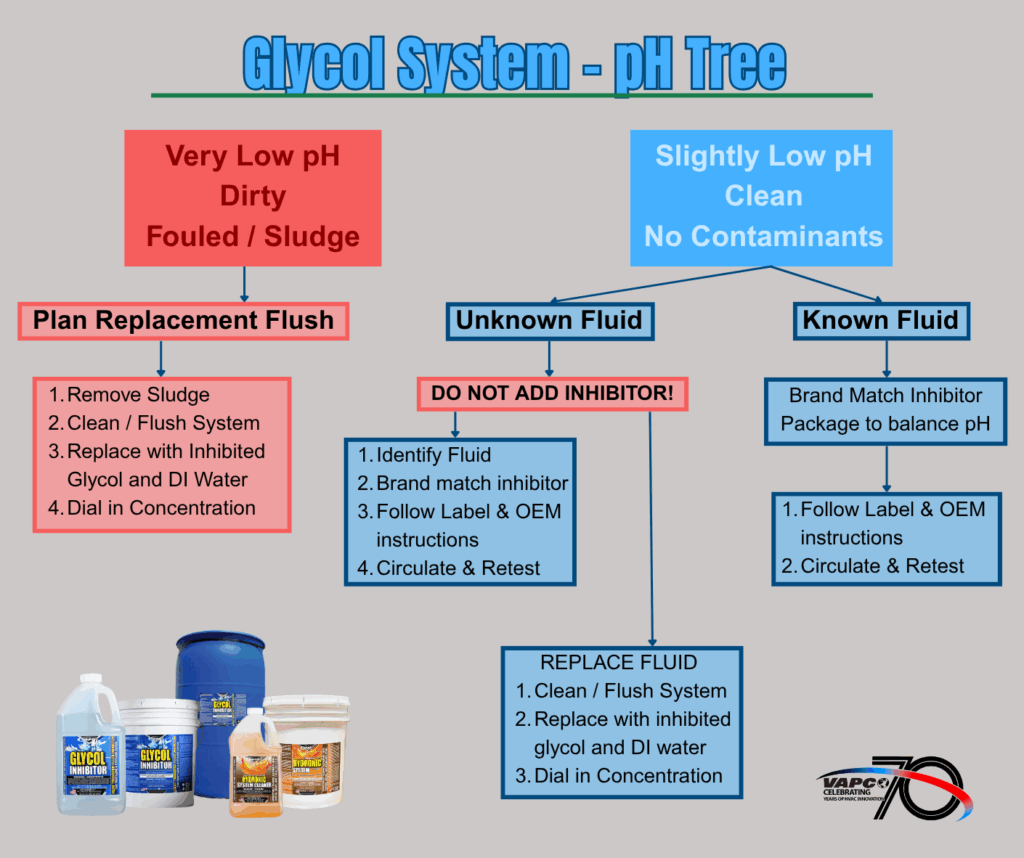

When to Use Vapco Glycol Inhibitor

Once testing is complete, the results dictate the action. If pH is only slightly low and the fluid is otherwise clean, a booster may work. However, severely degraded fluids require replacement.

The Correction Process

For a mildly acidic system using Vapco inhibited glycol, Vapco Glycol Inhibitor is the designed solution. This product is formulated to complement our specific glycol chemistry. It helps restore the recommended pH range and boosts the inhibitor reserve.

Add the product precisely per the label instructions. Subsequently, circulate the fluid thoroughly after dosing. Then, re-test after the system fully mixes and stabilizes. This stabilization often requires several hours, not just minutes. Never overdose the system with any inhibitor package.

When a Flush is Necessary

If the pH is very low, RA is depleted, or corrosion metals are high, a full flush is required. This action is also needed if the fluid is discolored or sludged. Plan a corrective flush immediately. Mechanically remove sludge first, perhaps with magnetic separation. Consider using a system cleaner where appropriate. We offer Hydronic System Cleaner (HSC) in a variety of sizes to help with mild system flushes.

Refill the system with fresh, properly inhibited glycol premix. Always use deionized or low-TDS (total dissolved solids) water for makeup. Set the concentration for your climate using a calibrated refractometer. This practice ensures maximum freeze protection and efficiency.

Best Practices for Longevity

Successful fluid maintenance involves more than just adding a Glycol Inhibitor. Proper makeup water and protection against contaminants are equally important as regular checks, to ensure a long lasting system.

Water Quality and Protection

Always use deionized or low-TDS (total dissolved solids) water for mixing glycol and for makeup. Hardness must be kept very low to prevent scale formation. Keeping chlorides and sulfates low is also critical, especially for aluminum and stainless steel systems.

Eliminate air to prevent inhibitor consumption. Use a quality microbubble air separator. Verify automatic air vents and system pressure settings regularly. Install a quality magnetic or dirt separator. This action will capture magnetite and protect pumps and heat exchangers.

Simple Winterization Workflow ❄️

| Phase | Action | Detail |

| Assess | Verify necessity, system specifics, and glycol type. | MUST BE VERIFIED: Check that the system contains Vapco Inhibited Glycol. Verify if glycol is required. Identify metallurgy (types of metals used) and OEM limits (Original Equipment Manufacturer restrictions) for the glycol type and concentration. |

| Test | Evaluate current fluid condition. | Test for: pH, RA (Reserve Alkalinity), glycol % (concentration), iron/copper(corrosion products), hardness/TDS (Total Dissolved Solids), and chlorides/sulfates (corrosion promoters). |

| Correct | Adjust fluid properties. | Adjust concentration to meet winter protection requirements. For mild acidity in Vapco glycol, dose Vapco Glycol Inhibitor per label. For severe issues (e.g., high corrosion or extreme contamination), flush and refill with fresh inhibited glycol. |

| Protect | Safeguard the system. | Eliminate air from the system (a major cause of corrosion), add magnetic/dirt separation (to remove particulates), and ensure the makeup water is clean(e.g., deionized or distilled). |

| Verify | Confirm system stability and protection. | Circulate the fluid, then re-test after the system has stabilized. Recheck againafter a few days of operation to ensure conditions remain acceptable. |

Industry & Professional Standards

These links point to highly authoritative organizations that set industry-wide best practices.

ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers)

Link Text: ASHRAE Guidelines on HVAC System Maintenance

URL:

https://www.ashrae.org/technical-resources/bookstore/standards-and-guidelines(Note: This links to the main Standards and Guidelines page where specific Handbooks (like HVAC Applications) are referenced.)

ASME Piping Standards (B31.1 & B31.3 Context)

Link Text: Overview of ASME B31.1 and B31.3 Piping Codes

URL:

https://www.asme.org/codes-standards/find-codes-standards/b311-2020-power-piping(Note: This links to the B31.1 Power Piping standard, which is most relevant to industrial/institutional HVAC, and often discussed alongside B31.3.)

II. Glycol Fluid Maintenance & Chemistry

These links provide in-depth information on system testing, pH targets, and the chemistry of inhibitors.

General Glycol Fluid Testing & pH

Link Text: Guide to Testing Glycol Freeze Point, pH and Inhibitor Levels

Glycol System Maintenance & pH Range

Link Text: Glycol Cooling Systems Maintenance Guide for Facility Managers

URL:

https://towerwater.com/glycol-cooling-systems-maintenance-guide/(Note: This resource specifically discusses the pH range of 8.0 to 10.0 and inhibitor depletion.)

III. System Integrity & Component Protection

This link focuses on the core problem your product solves: corrosion prevention.

Inhibitors and Corrosion Prevention

Link Text: Selecting and Maintaining Glycol Based Heat Transfer Fluids (White Paper)

URL:

https://www.chemaqua.com/en-gb/wp-content/uploads/sites/8/2024/07/Guideline-for-Selecting-Glycol.pdf(Note: This is a Chem-Aqua white paper that provides excellent technical detail on corrosion, degradation, and the role of inhibitors)

Check out more What’s New in HVAC articles here: Full Archive: https://whatsnewinhvac.com/full-archive/

Top 10 Glycol Inhibitor FAQ

What is the single most important routine check for a glycol system?

The single most important routine check is testing the fluid’s pH level using a calibrated meter.

Why must Vapco Glycol Inhibitor be used only with Vapco inhibited glycol?

It must be used with Vapco inhibited glycol because mixing different, unknown, or dissimilar inhibitor chemistries can lead to precipitation, gelling, or a loss of corrosion protection.

What does Vapco Glycol Inhibitor do for a system with mild acidity?

It is formulated to restore a healthy pH range and boost the inhibitor reserve in systems using Vapco glycol that have become mildly acidic.

Why should a professional use a calibrated meter instead of pH strips?

A calibrated meter provides the precision and accuracy needed for proper chemical adjustment, whereas pH strips are not precise enough for the narrow and critical ranges required in multi-metal systems.

If the fluid is severely sludged or the reserve alkalinity RA is depleted, should I add an inhibitor?

No. Severe degradation, heavy sludge, or depleted RA requires a full system flush and refill with fresh inhibited glycol, not just an additive.

What other fluid tests should be performed besides pH?

You should also test the Reserve Alkalinity RA, glycol concentration (freeze point), iron/copper, hardnessTDS, chlorides, and sulfates.

What type of water should be used for mixing glycol or for makeup water?

You should always use deionized (DI) or low-TDS (total dissolved solids) water for mixing and makeup to prevent the introduction of hard minerals, which can cause scale and deplete inhibitors.

What is a major risk of over-concentrating glycol (above 55%)?

Over-concentrating glycol does not necessarily improve protection; instead, it reduces heat transfer efficiency and significantly increases the fluid’s viscosity, straining the system’s pump. It can also over-concentrate inhibitors that are designed to be used at specific strengths for system protection.