Compliance and Cost: Choosing the Right Propylene Glycol for HVACR

Introduction: The Importance of Choosing the Right Propylene Glycol

Introduction: The Importance of Choosing the Right Propylene Glycol

Choosing the Right Propylene Glycol is a critical decision in any hydronic or HVACR installation. This fluid provides essential freeze protection and corrosion control, ensuring system longevity. However, confusion persists over which type is necessary: standard inhibited glycol, NSF HT-1 registered glycol, or specialty “food grade” purities. The correct choice impacts performance, compliance, and, crucially, your project’s cost.

This article clarifies these differences, empowering you to choose confidently and avoid unnecessary expenses. Importantly, all Vapco glycols are built on PG that is Generally Recognized As Safe (GRAS) by the FDA (see 21 CFR 184.1666).

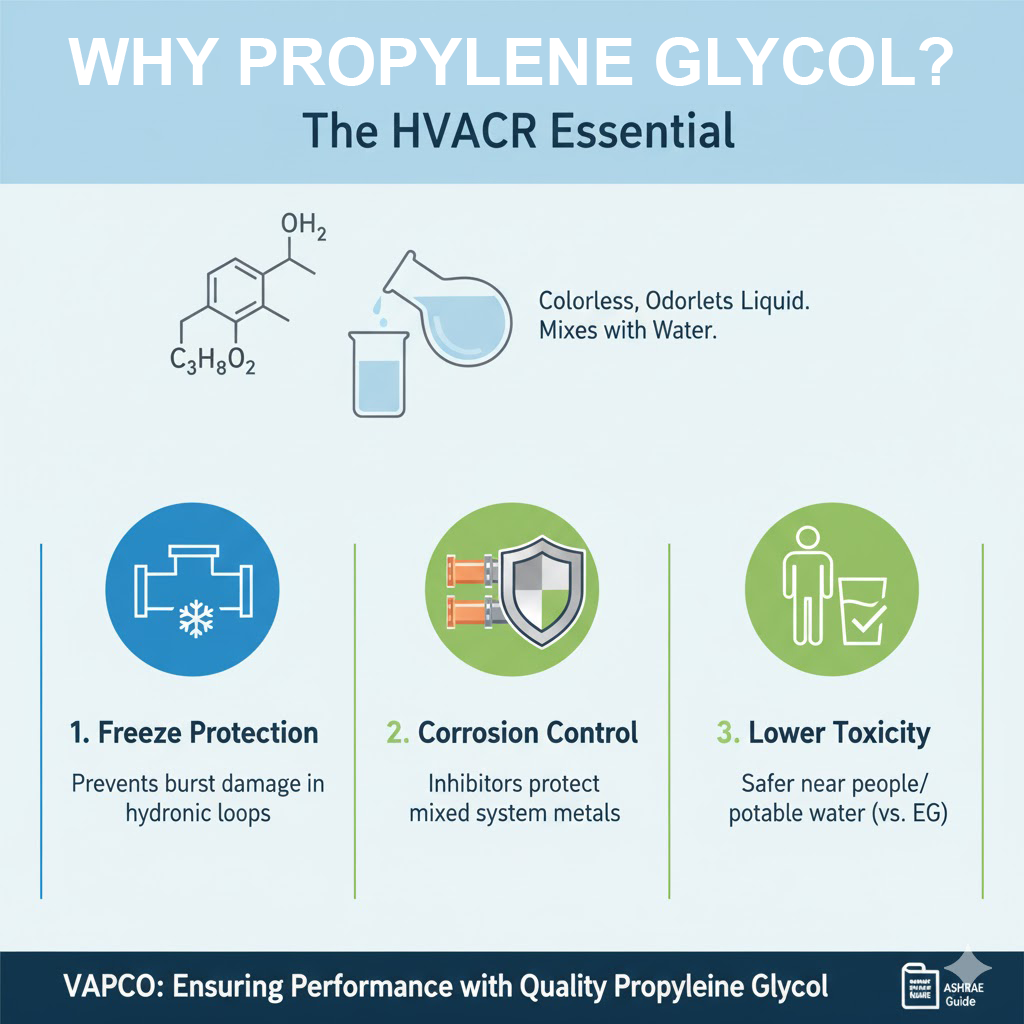

Propylene Glycol Fundamentals for Contractors

Propylene glycol is a nearly colorless liquid. It mixes readily with water and forms the foundation for reliable heat transfer fluids.

Why Quality Propylene Glycol is Essential

System Protection: It prevents burst damage from freezing in hydronic loops and offers corrosion defense when properly inhibited.

Safety Profile: PG has a lower toxicity profile than ethylene glycol (EG). Therefore, it is the preferred choice near occupied spaces or potable water lines.

Performance: A high-quality formulation ensures broad compatibility with system materials and stable operation.

A good installation starts with quality fluid. Always consult technical resources like the ASHRAE Handbook for best practices on secondary coolants.

Three Types: Choosing the Right Propylene Glycol for Compliance

Understanding the regulatory context helps you select the correct product. Purity requirements dictate price and application.

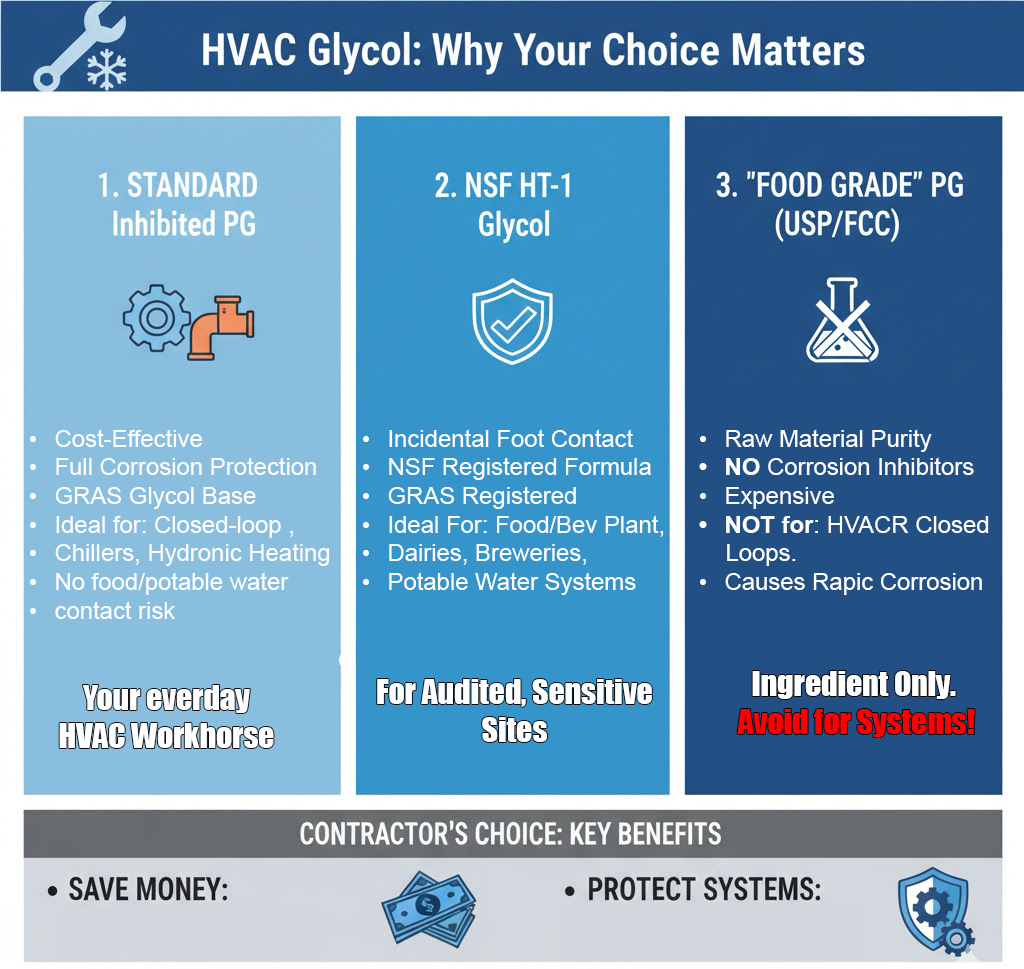

Standard Inhibited PG: The Workhorse Solution

Standard inhibited PG is a complete, economical heat transfer fluid. It combines GRAS Propylene Glycol with a robust inhibitor package to protect mixed metals and stabilize pH.

When to Choose It: For most general HVACR applications. This includes closed-loop chilled water systems, general hydronic heating, snowmelt, and ground loops. Use it wherever there is no credible path to contact with food, beverages, or potable water.

Contractor Takeaway: This is your default, cost-effective choice for standard installations. Maintenance—annual testing of concentration and inhibitors—is key to system longevity.

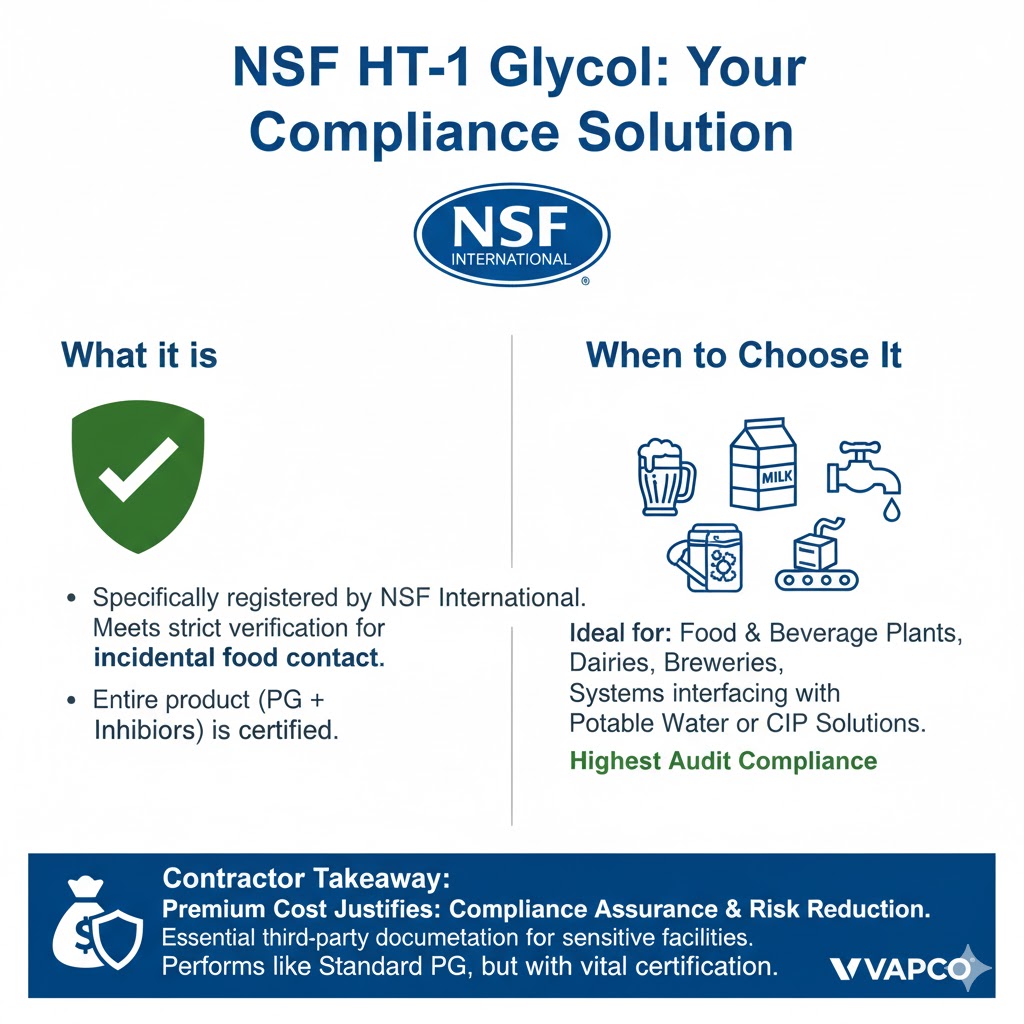

NSF HT-1 Glycol: Compliance for Food & Beverage

NSF HT-1 is specifically registered by NSF International for use where incidental food contact is possible. The entire product, including the base PG and every inhibitor, meets this strict verification standard.

When to Choose It: In food processing plants, breweries, dairies, and facilities that require the highest audit compliance. Choose it anytime there is a heat exchanger that interfaces with potable water or CIP (Clean-In-Place) solutions.

Contractor Takeaway: The premium cost justifies the compliance assurance and risk reduction in highly audited or sensitive facilities. This fluid performs like standard inhibited PG but provides necessary third-party documentation.

True Food Grade PG (USP/FCC): Avoid Over-Specification

“Food Grade” (FCC) or Pharmaceutical Grade (USP) refers only to the base raw material’s purity. It is used in food or cosmetics as an ingredient. It is not a complete heat transfer fluid.

Key Fact: USP/FCC propylene glycol lacks the corrosion inhibitors needed for closed-loop HVACR systems. Using it alone will lead to rapid equipment damage.

Contractor Takeaway: Avoid specifying pure USP/FCC PG unless the specification is explicitly for an ingredient application. If the site requires food-safe fluid, recommend NSF HT-1 Glycol instead, as it is inhibited and registered for the mechanical system use.

Value vs. Risk: Why Quality PG Matters

The cost difference between glycols should never justify poor fluid quality. Low-cost industrial options often use poorly refined PG containing harmful contaminants like chlorides, sulfates, or high acidity.

Risks to Avoid: These contaminants cause pitting, scale, and accelerated corrosion. Sludge and fouling compromise heat transfer and clog filters, drastically increasing the Total Cost of Ownership (TCO).

Vapco Quality Assurance: We only use virgin PG or high-quality reclaimed PG refined to near-pharmaceutical standards. We blend using an on-site DI water treatment system for consistency. This process ensures a clean, consistent fluid that protects the equipment you install.

Always request a Certificate of Analysis (COA) to verify the purity, water content, and contaminant levels of the glycol you purchase. Choosing the Right Propylene Glycol is about value, not just the lowest price per gallon.

Conclusion and Next Steps

By distinguishing between Standard Inhibited PG, NSF HT-1 Glycol, and raw USP/FCC PG, you can make informed decisions that save clients money while ensuring compliance. Standard PG is for non-contact systems. NSF HT-1 is for incidental contact systems.

FAQ: Choosing the Right Propylene Glycol

Q: What are the three main types of propylene glycol (PG) I need to know about for HVACR systems?

A: HVACR contractors primarily deal with three types when Choosing the Right Propylene Glycol:

Standard Inhibited PG: The industrial workhorse for general closed loops.

NSF HT-1 Glycol: A registered formula for systems requiring incidental food contact compliance.

Food Grade (USP/FCC) PG: The raw material purity used as an ingredient; it is generally uninhibited.

Q: Why can’t I use “Food Grade” or USP/FCC propylene glycol in a closed-loop chiller?

A: You must avoid using pure USP/FCC PG alone in a closed-loop system. While it is high-purity, it lacks the necessary corrosion inhibitors. Using uninhibited PG will accelerate corrosion, cause system damage, and compromise the longevity of your HVACR equipment.

Q: What is the difference between Standard Inhibited PG and NSF HT-1 Glycol?

A: The key difference is regulatory compliance for incidental contact.

Standard Inhibited PG is fully formulated and protected but is intended for systems with no credible path to food, beverage, or potable water contact.

NSF HT-1 Glycol is also fully inhibited but its complete formulation is third-party registered by NSF for incidental contact with food or drinking water.

Q: When should I recommend Vapco NSF HT-1 Glycol?

A: Recommend NSF HT-1 Glycol whenever the system installation involves:

Food processing plants (dairies, meat packaging, bakeries).

Beverage production facilities (breweries, wineries).

Any heat exchanger where a breach could lead to fluid contact with potable water or a food product. This choice ensures audit readiness and compliance.

Q: Is Vapco’s Standard Inhibited Propylene Glycol safe?

A: Yes. Vapco’s Standard Inhibited PG is safe for its intended use. It is built on base propylene glycol that is GRAS (Generally Recognized As Safe) by the FDA. The “Standard” formulation is designed for superior corrosion protection in technical, non-food-contact applications.

Q: Does Vapco use quality ingredients in its Standard Inhibited PG?

A: Absolutely. Vapco prioritizes quality. We use virgin PG or high-quality reclaimed PG refined to near-pharmaceutical specifications. We also blend with on-site DI (deionized) water and custom-blend our inhibitors to ensure a clean, consistent fluid that protects equipment better than cheaper, lower-grade alternatives.

Q: How does Choosing the Right Propylene Glycol impact project cost?

A: The wrong choice impacts cost in two ways:

Over-specification: Using high-cost, specialty fluids like pure USP/FCC PG when Standard Inhibited PG would suffice unnecessarily increases material costs.

System Failure: Using uninhibited or low-quality glycol (even standard grade) leads to accelerated corrosion, repairs, and system replacement, drastically increasing the Total Cost of Ownership (TCO).

For more information:

For HVAC contractors making critical decisions about Choosing the Right Propylene Glycol, access to authoritative technical and regulatory information is essential. Use these resources to verify specifications and ensure compliance.

ASHRAE Handbook (Secondary Coolants)

Description: The definitive industry reference for guidance on the physical properties, application standards, and maintenance of secondary coolants (brines), including propylene glycol solutions, in HVAC and refrigeration systems.

NSF International HT-1 Registration Guidelines

Description: Official documentation detailing the requirements and standards for heat transfer fluids registered as HT-1. This is the resource required to confirm a fluid is appropriate for systems where incidental food or potable water contact is possible.

FDA Propylene Glycol GRAS Status (21 CFR 184.1666)

Description: Direct link to the U.S. Food and Drug Administration’s (FDA) Code of Federal Regulations confirming the Generally Recognized As Safe (GRAS) status of the base Propylene Glycol material for its intended uses.