High Solids Cylinder Adhesive (Low-VOC) | Magna Tack MT-Series

The “Swiss Army Knife” for Industrial Insulation & Construction.

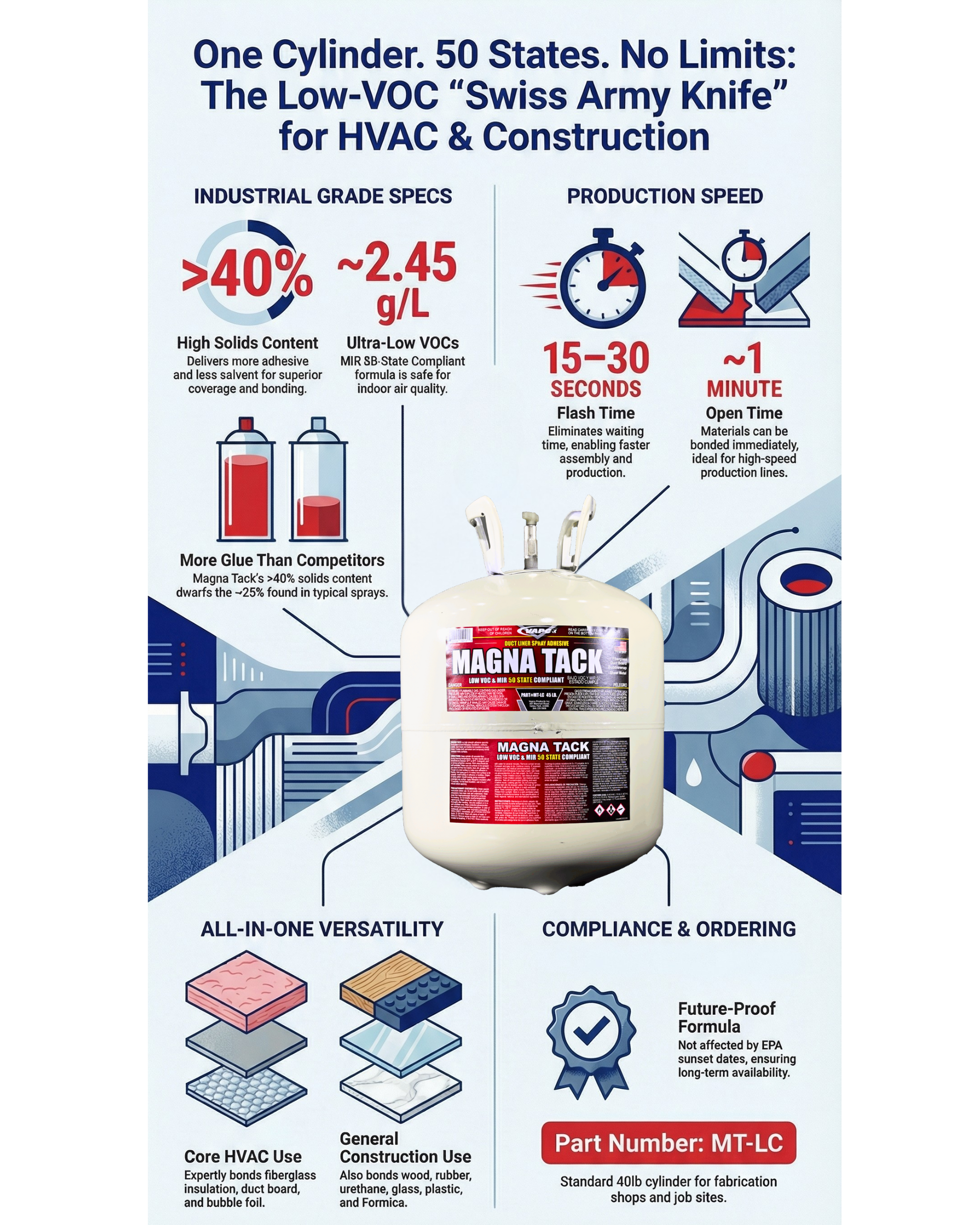

Magna Tack (MT) proves that “Compliant” doesn’t mean “Weak.” While many low-VOC adhesives are watery and slow to dry, Magna Tack is engineered with a Heavy-Duty 42% Solids profile. This is a true industrial contact cement designed for high-speed production lines that cannot afford to wait for weak glues to tack up.

Because it is MIR 50-State Compliant, you get the best of both worlds: The aggressive grab of a legacy solvent glue, with a modern formula that is legal to sell and use in every state—including California.

The Efficiency Math: Why Use a High Solids Cylinder Adhesive?

Efficiency drives profitability. Because Magna Tack contains significantly more rubber and resin than economy sprays, it sits on top of porous surfaces like duct insulations rather than soaking in. This creates a stronger bond with less product.

Manufacturer’s Tech Note: Because of the heavy 42% solids content, standard spray tips may clog or spray unevenly. You must use Tip 6501 or Tip 730116. These specific tips are engineered to atomize the high-density rubber/resin blend into a perfect web pattern. (Both tips come standard with our SPG-AG gun).

- High-Solids (>42%): Delivers a heavier adhesive load per spray. Bridges gaps on porous fiberglass and duct board without soaking in, ensuring a permanent bond.

- Rapid Flash (15-30s): Designed for high-speed production. The solvent flashes off almost instantly, allowing for immediate mating of materials.

- Safety Profile: Despite its strength, MT-LC maintains an ultra-low VOC profile of just 2.45 g/L. This protects user safety and indoor air quality.

Professional Application: Ideal for duct liner, fiberglass insulation, urethane, rubber, glass, and metal-to-metal bonding.

| KEY FEATURE / SPECIFICATION |

TRADE BENEFIT / RESULT |

| MIR 50-State Compliant |

Universal Logistics: Fully legal in all 50 states. Eliminates shipping restrictions and the need for regional SKUs, unlike standard California-only compliant adhesives. |

| Rapid Tack & Open Time |

Instant Grab for Speed: Solvent flashes in 15-30 seconds with a ~1 minute open time. Designed for high-speed production where immediate hold is required. |

| High Solids Content: >40% |

Superior Yield & Bridging: Delivers a heavier adhesive load per spray. Bridges gaps on porous fiberglass and duct board without soaking in, ensuring a permanent bond with less product usage. |

| Multi-Substrate Versatility |

The “Swiss Army Knife” Bond: Goes beyond duct liner. Securely bonds wood, urethane, rubber, glass, ceramic, plastic, and Formica. |

| Ultra-Low VOC Formulation |

Industrial Safety: Engineered to meet strict air quality standards while maintaining the aggressive tack required for heavy-duty HVAC and construction applications. |

| Web Spray Pattern |

Control & Speed: Ensures precise application with minimal overspray. Fast tack-up allows for immediate handling and mating of materials. |

| Recommended Tips |

Optimized Flow: For best results with this high-solids formula, use Tip 6501 or Tip 730116. Both come in SPG-AG, try both to determine which works best for your needs. |

| Waterproof & Non-Staining |

Long-Term Durability: Safe for use on exposed surfaces and in environments subject to humidity or temperature fluctuations. |

Vapco Field Guide: Adhesion Matrix

How Magna Tack performs on common substrates. (★★★ = Best in Class)

| SUBSTRATE |

RATING |

WHY IT WINS |

| Duct Liner / Fiberglass |

★★★ |

High Solids formula bridges gaps and sits on top of porous fibers rather than soaking in. |

| Sheet Metal (Galvanized) |

★★★ |

Instant Tack: Aggressive grab on smooth, non-porous metals. |

| Vinyl / Rubber / EPDM |

★★★ |

Strong contact bond that resists plasticizer migration and humidity. |

| Porous (Wood/Concrete) |

★★★ |

Web pattern seals the surface, creating a unified bonding layer instantly. |

| Temperature Warning |

CRITICAL |

Do not apply below 60°F. Cold cylinders lose pressure, causing the high-solids fluid to “spit” rather than spray. |

Part Number Reference:

Select the right cylinder size for your job. Don’t forget the hose, spray gun, and remover.

1. Select Your Cylinder

| PART # |

NET WEIGHT |

APPLICATION FIT |

| MT-SC |

11 lbs |

Portable / Service: Lightweight disposable tank for rooftops, smaller installations, and repair work. |

| MT-LC |

35 lbs |

Shop Standard: The #1 choice for fabrication shops. Best balance of mobility and volume. |

| MT-200 |

180 lbs |

Production: High-volume stationary setup for automated lines or large duct runs. |

Contractors: Please contact your local Vapco distributor for pricing and availability.

2. Essential Accessories

Professional equipment is required to spray high-solids adhesives.

| ACCESSORY |

PART # |

DETAILS |

| Spray Gun |

SPG-AG |

Adjustable Volume Control: Includes Tip 6501 & 730116 specifically for Magna Tack. |

| Hose Assembly |

THA-6, 12, 18 |

Teflon Lined: Available in 6ft, 12ft, and 18ft lengths. Resistant to kinking and solvent breakdown. |

| Cleanup |

UAR-SC |

Universal Adhesive Remover: Essential for cleaning gun tips and overspray. Connects directly to hose for flushing. |

Maintenance Tip: If the cylinder will sit for more than a few days, close the valve, purge the hose, and connect to UAR-SC to flush the line. High-solids adhesives will clog guns if left to dry inside the line.

FAQs

Frequently Asked Questions: Magna Tack (MT)

Application & Performance

Q: What spray tip should I use for Magna Tack?

A: Because Magna Tack has a very high solids content (>40%), you must use specific tips to ensure a proper web pattern. We recommend Tip 6501 or Tip 730116. Different tips may cause sputtering, streaming, or uneven coverage due to the thickness of the adhesive.

Q: What is the tack time and open time?

A: Do not wait! Magna Tack is engineered for high-speed production. It flashes off in just 15–30 seconds. Once tacky, you have a short open window of approximately 1 minute to mate the surfaces. If you wait too long, the adhesive will lose its grab.

Q: Can I use this on Styrofoam or Polystyrene?

A: Generally, No. Like most solvent-based industrial adhesives, the carrier solvents can attack low-density polystyrene foam (EPS). However, it is excellent for urethanes, rubber, and fiberglass. Always perform a small patch test before using on sensitive plastics.

Q: Is this a “Contact Adhesive”? Do I spray one side or two?

A: Yes, this is a true contact adhesive. For a permanent, industrial-grade bond, you must spray a uniform web coat on BOTH surfaces (the substrate and the material). Allow 15-30 seconds to tack, then compress them together immediately.

Q: Is Low-VOC adhesive strong enough (High Solids)?

A: Yes. Standard adhesives are often ~20-30% solids, meaning you are paying for solvent that just evaporates. Magna Tack is >40% solids. This means more actual glue stays on the surface, bridging gaps in porous duct liner better and requiring fewer passes to get a strong bond.

Troubleshooting

Q: Why is the spray pattern inconsistent or “spitting”?

A: This usually indicates one of a few things:

- Wrong Tip: You must use Tip 6501 or 730116. Smaller tips cannot handle the high-solids flow.

- Cold Cylinder: The adhesive is too cold. Maintain the cylinder between 60°F – 90°F. If the cylinder is cold, the pressure drops, and the adhesive thickens, leading to a poor spray pattern.

- Clogged Equipment: If the hose or tip sits too long with product not being used, the glue can start to setup. Use universal adhesive remover (UAR-SC) to purge the hose and tip of dry adhesive.

Q: Why is my bond failing?

A: Production Speed. If the bond is failing, you are likely waiting too long. Because this is a fast-tack formula, you must mate the materials within 60 seconds of spraying.

Safety & Compliance

Q: Is Magna Tack Flammable?

A: During Application: YES. The solvent carrier (Methyl Acetate) is flammable. You must keep the spray area free of sparks, pilot lights, and open flames.

After Curing: NO. Once the solvent evaporates (which happens very quickly), the remaining adhesive bond line is non-flammable.

Q: Does this product contain Methylene Chloride or Perc?

A: No. Magna Tack is free of chlorinated solvents, including Methylene Chloride and Perchloroethylene. This makes it a safer, lower-toxicity option compared to older chemical formulas.

Q: Can I sell or use this product in California?

A: YES. Unlike many competitors, Magna Tack is MIR 50-State Compliant. It meets the strict Low-VOC air quality regulations of California (SCAQMD), Utah, and the OTC states, allowing for unrestricted use nationwide.

Q: What is the VOC content?

A: Magna Tack is an Ultra-Low VOC formula containing approximately 2.45 g/L. This is significantly lower than standard flammable contact adhesives, which helps facilities meet “Green Building” and LEED standards.

Logistics & Storage

Q: What is the shelf life of a cylinder?

A: Magna Tack cylinders have a manufacturer warranty of 1 year from the date of manufacture when stored correctly. Always store cylinders off the concrete floor in a cool, dry area. Do not expose to temperatures above 120°F (49°C).

Q: Is this product affected by the EPA “Sunset Dates”?

A: No. While other adhesives (like those containing HFCs or Perc) face bans in 2026/2027, Magna Tack is a future-proof formula. It has no upcoming EPA phase-out dates, making it a secure long-term solution for your inventory.

Q: What sizes are available?

A: The standard size for industrial fabrication is:

- MT-SC (Small Cylinder): A portable 11 lb cylinder. Think of it like a massive aerosol can (holds roughly 13-20 cans worth).

- MT-LC (Large Cylinder): The standard 35 lb shop/job site cylinder.

- MT-200: Industrial 180 lb cylinder for high-volume fabrication runs.

Q: How do I dispose of the cylinder?

A: The MT-LC is a non-refillable DOT 39 cylinder. Once empty, turn the valve open to release any remaining pressure, punch the knock-out plug (if equipped), or follow your local scrap metal recycling guidelines for empty steel pressure vessels. Never incinerate or puncture a pressurized cylinder.

SDS & Instructions

📄 DOWNLOAD FULL SDS (PDF)

⚠️ Professional Use Only | Flammable

EXTREMELY FLAMMABLE. Contains gas under pressure; may explode if heated. Causes skin irritation and serious eye irritation. Keep away from heat, sparks, open flames, and hot surfaces. No smoking.

Field Guide: Adhesion Matrix

Magna Tack utilizes a high-solids (42%) synthetic rubber resin designed to bridge gaps on porous surfaces. The following matrix details performance against common construction substrates.

| SUBSTRATE |

TYPE |

RATING |

PERFORMANCE / WHY IT WORKS |

| Fiberglass / Duct Liner |

Porous / Fibrous |

★★★ BEST |

Gap Bridging: High-solids content sits on top of the fibers rather than soaking in, creating an instant web-lock. |

| Galvanized Steel |

Non-Porous Metal |

★★★ BEST |

Instant Tack: Aggressive solvent flash-off creates immediate grab on smooth, non-porous metals. |

| Reflective / Bubble Wrap |

Foil Faced |

★★★ BEST |

Surface Safe: Web pattern bonds the foil facing instantly without eating into the bubble core or causing shrinkage. |

| Polystyrene Foam |

Sensitive Plastic |

⚠️ TEST |

Solvent Sensitivity: Solvent-based adhesives may attack certain expanded foams. Always test a small area first. |

Substrate Compatibility Protocol

| MATERIAL / COMPONENT |

STATUS & PROTOCOL |

| Fiberglass Insulation (Duct Liner) |

✅ RECOMMENDED

Primary Application. Web spray prevents soak-in. |

| Reflective Insulation (Bubble Wrap) |

✅ RECOMMENDED

Ideal for bonding aluminum-faced bubble wrap to metal ductwork. |

| Sheet Metal / Duct Work |

✅ RECOMMENDED

Galvanized, Stainless, and Aluminum. Ensure surface is oil-free. |

| Concrete / Masonry |

✅ RECOMMENDED

Ensure surface is dry and dust-free before application. |

| Vinyl (Flexible) |

⚠️ CAUTION

Resists plasticizer migration, but high-tension applications should be tested. |

Temperature Warning (The Cold Cylinder Rule):

DO NOT APPLY BELOW 60°F. Cold cylinders lose pressure, preventing the high-solids fluid from atomizing. This results in “spitting” rather than a web spray, causing uneven coverage and weak bonds. Warm cylinder to room temperature before use.

Directions for Low-VOC HVAC Cylinder Spray Adhesive:

MT-SC, LC, 200

1. Preparation & Setup

Step 1: Ventilation. Ensure the area is well-ventilated. Eliminate all ignition sources (pilot lights, sparks).

Step 2: Surface Prep. Surfaces must be clean, dry, and free of oil or grease.

Step 3: Connect Equipment. Attach the hose to the cylinder and the spray gun to the hose. Tighten with a wrench.

Tech Tip: For the Magna Tack 42% Solids formula, you MUST use Tip 6501 or Tip 730116. Standard tips will not create the proper web pattern.

2. Application (The 30-Second Rule)

Magna Tack is designed for speed. Follow the timing closely.

- Spray Technique:

- Hold gun 6-10 inches from surface.

- Apply a uniform web coat to BOTH surfaces (80-100% coverage).

- Move quickly—do not allow adhesive to puddle.

- Flash-Off (Wait Time):

- Wait 15 to 30 seconds.

- The solvent needs to evaporate to become “tacky.”

- Test: Touch with knuckle—adhesive should be sticky but not transfer to skin.

3. Bonding & Cleanup

- Mate Surfaces:

- The Window: You have 1-3 minutes to bond the materials.

- Press surfaces together firmly, applying pressure from the center outward.

- Bond is immediate. Parts can be handled right away.

- Cleanup:

- Turn Off: Close cylinder valve.

- Purge: Trigger gun until only gas comes out to clear the line.

- Flush: If storing for >2 days, attach UAR-SC (Adhesive Remover) to flush the gun/hose and prevent clogging.

🧪 SDS SECTION: MAGNA TACK ADHESIVE

(MT-Series)

1. Identification & Supplier Details

| Product Name |

Magna Tack Low VOC Spray Adhesive |

| Product Numbers |

MT-SC, MT-LC, MT-200 |

| Recommended Use |

Industrial Adhesive (Cylinder) |

| Emergency Phone |

(800) 255-3924 |

2. Hazards Identification

| GHS Classification |

Flammable Aerosol (Cat 1)

Gas Under Pressure (Liquefied Gas)

Skin Irritation (Cat 2) / Eye Irritation (Cat 2A) |

| Signal Word |

DANGER |

| Hazard Statements |

H222: Extremely flammable aerosol.

H280: Contains gas under pressure; may explode if heated.

H319: Causes serious eye irritation. |

| Precautionary Statements |

P210: Keep away from heat/sparks/open flames/hot surfaces. No smoking.

P211: Do not spray on an open flame or other ignition source.

P251: Pressurized container: Do not pierce or burn, even after use.

P410+P412: Protect from sunlight. Do not expose to temperatures exceeding 50°C/122°F. |

3. Composition / Ingredients

| Component Name |

CAS Number |

Concentration |

| Methyl Acetate |

79-20-9 |

30 – 60% |

| Synthetic Polymer Resin |

Proprietary |

15 – 40% |

| Liquefied Petroleum Gas |

68476-86-8 |

10 – 30% |

4. First-Aid Measures

| Skin Contact |

Wash with soap and water. Remove contaminated clothing. If irritation persists, seek medical attention. |

| Eye Contact |

Rinse cautiously with water for several minutes. Remove contact lenses if easy to do. |

| Inhalation |

Remove person to fresh air. If drowsiness or dizziness occurs, get medical advice. |

| Ingestion |

Rinse mouth. Do NOT induce vomiting due to aspiration hazard. |

5. Fire-Fighting Measures

| Suitable Extinguishing Media |

CO2, dry chemical, foam. Do not use direct water stream (may spread fire). |

| Specific Hazards |

Extremely flammable. Vapors are heavier than air and may travel to ignition sources. Cylinders may explode in heat. |

| Protective Equipment |

Wear SCBA and full protective gear. Use water spray to keep cylinders cool. |

6. Accidental Release Measures

| Personal Precautions |

Eliminate all ignition sources. Ventilate area. Wear PPE (gloves, safety glasses). |

| Cleanup Methods |

Absorb with inert material (sand, vermiculite). Do not use combustible materials. Transfer to hazardous waste container. |

7. Handling & Storage

| Safe Handling |

Use only in well-ventilated areas. Ground/bond container and receiving equipment. Do not breathe spray. |

| Safe Storage |

Store in a cool, dry place. Do not store above 120°F (50°C). Keep away from direct sunlight and heat sources. |

8. Exposure Controls / Personal Protection

| Exposure Limits |

Methyl Acetate: ACGIH TWA 200 ppm / STEL 250 ppm. |

| Engineering Controls |

Explosion-proof ventilation equipment recommended in confined spaces. |

| PPE |

Eyes: Safety glasses with side shields. Skin: Solvent-resistant gloves. |

9. Physical & Chemical Properties

| Physical State |

Liquid (Aerosol / Cylinder) |

| Color / Odor |

Clear or Amber / Solvent Odor |

| VOC Content |

< 2.45 g/L (Low VOC) |

| Solids Content |

~ 42% |

10. Stability & Reactivity

| Stability |

Stable under normal conditions. |

| Conditions to Avoid |

Heat, sparks, open flames, hot surfaces. |

| Incompatible Materials |

Strong oxidizers, acids, bases. |

11. Toxicological Information

| Acute Toxicity |

Methyl Acetate: LD50 Oral (Rat) > 5000 mg/kg. |

| Skin/Eye |

Causes serious eye irritation. May cause drowsiness or dizziness. |

12. Ecological Information

| Ecotoxicity |

Not classified as hazardous to the aquatic environment. |

| Persistence |

Solvents are readily biodegradable. |

13. Disposal Considerations

| Disposal Method |

Dispose of contents/container in accordance with local/federal regulations. Do not puncture. |

| Waste Code |

D001 (Ignitable) |

14. Transport Information

| Regulation |

UN Number |

Class |

Proper Shipping Name |

| DOT (US) |

UN3501 |

2.1 |

Chemical under pressure, flammable, n.o.s. (Methyl Acetate) |

15. Regulatory Information

| US Federal |

TSCA: All components listed.

SARA 313: None.

MIR Compliance: 50-State Compliant. |

16. Other Information

| Preparation |

Prepared by: Vapco Technical Dept

Date: 2/14/2025

Version: 1.0 |

| Disclaimer |

The information provided is believed to be accurate but comes without warranty. User is responsible for full compliance with local regulations. |

Specs & Logistics

⚠️ DOWNLOAD TECHNICAL DATA REPORT (PDF)

1. Physical & Chemical Properties

| Base Chemistry |

Synthetic Polymer Resin / Methyl Acetate |

| Solids Content |

> 40% (High Solids) |

| VOC Content |

~ 2.45 g/L (Ultra-Low / 50-State Compliant) |

| Service Temp Range |

-20°F to 200°F (-29°C to 93°C) |

| Flammability (Wet) |

Flammable: Keep away from sparks/flames during spray. |

| Flammability (Cured) |

Non-Flammable: Bond line is non-flammable after solvent flash. |

| Appearance |

Clear / Amber |

| Shelf Life |

1 Year (Stored closed below 120°F) |

2. Application & Structural Performance

| Tack Time (Flash-Off) |

15 – 30 Seconds (Rapid Tack) |

| Open Time (Working Window) |

~ 1 Minute (Immediate Mating Required) |

| Peel Strength (180°) |

20 – 25 PIW (Aluminum to Fiberglass) |

| Shear Strength |

> 150 PSI (Wood to Wood / Static Load) |

| Cleanup Solvent |

Universal Adhesive Remover (UAR-SC) |

*Note: Estimated values based on lab formulations. Performance will vary based on application technique, substrate composition, and temperature.

3. Regulatory & Compliance

| Regulatory Status: |

MIR 50-State Compliant (No Regional Restrictions) |

| Proper Shipping Name: |

Chemical Under Pressure, Flammable, N.O.S. (Methyl Acetate) |

| UN Number: |

UN3501 |

| Hazard Class: |

2.1 (Flammable Gas) |

| Methylene Chloride: |

None (Free of Chlorinated Solvents) |

| Disposal Warning: |

Non-refillable cylinder. Federal law prohibits transportation if refilled. Penalty up to $500,000 (49 U.S.C. 5124). |

4. Master Shipping & Dimensions Guide

| ITEM |

INDIVIDUAL UNIT |

QTY / CASE |

CASE SPECS |

PALLET CONFIGURATION |

CODE |

| Part # |

Net Wt |

H (in) |

W (in) |

L (in) |

Units |

Gr Wt |

H (in) |

W (in) |

L (in) |

Cases/Pallet |

Total Units |

Wt (lbs) |

H (in) |

W (in) |

L (in) |

UPC |

MT-SC

(11 lbs) |

11 lbs |

[ ] |

[ ] |

[ ] |

1 |

[ ] |

[ ] |

[ ] |

[ ] |

[ ] |

[ ] |

[ ] |

[ ] |

40 |

48 |

[ ] |

MT-LC

(35 lbs) |

35 lbs |

17.63 |

12.0 |

12.0 |

1 |

45 lbs |

18.25 |

12.13 |

12.13 |

36 |

36 |

1610 |

59.75 |

40 |

48 |

683704150136 |

MT-200

(180 lbs) |

180 lbs |

[ ] |

[ ] |

[ ] |

1 |

[ ] |

[ ] |

[ ] |

[ ] |

[ ] |

[ ] |

[ ] |

[ ] |

40 |

48 |

[ ] |

Harmonized Tariff Code (HTS): 3506.91.0000 (Adhesives based on polymers/rubber)

NMFC Code: 4620 (Adhesives, Flammable Liquid/Gas) – Class 60