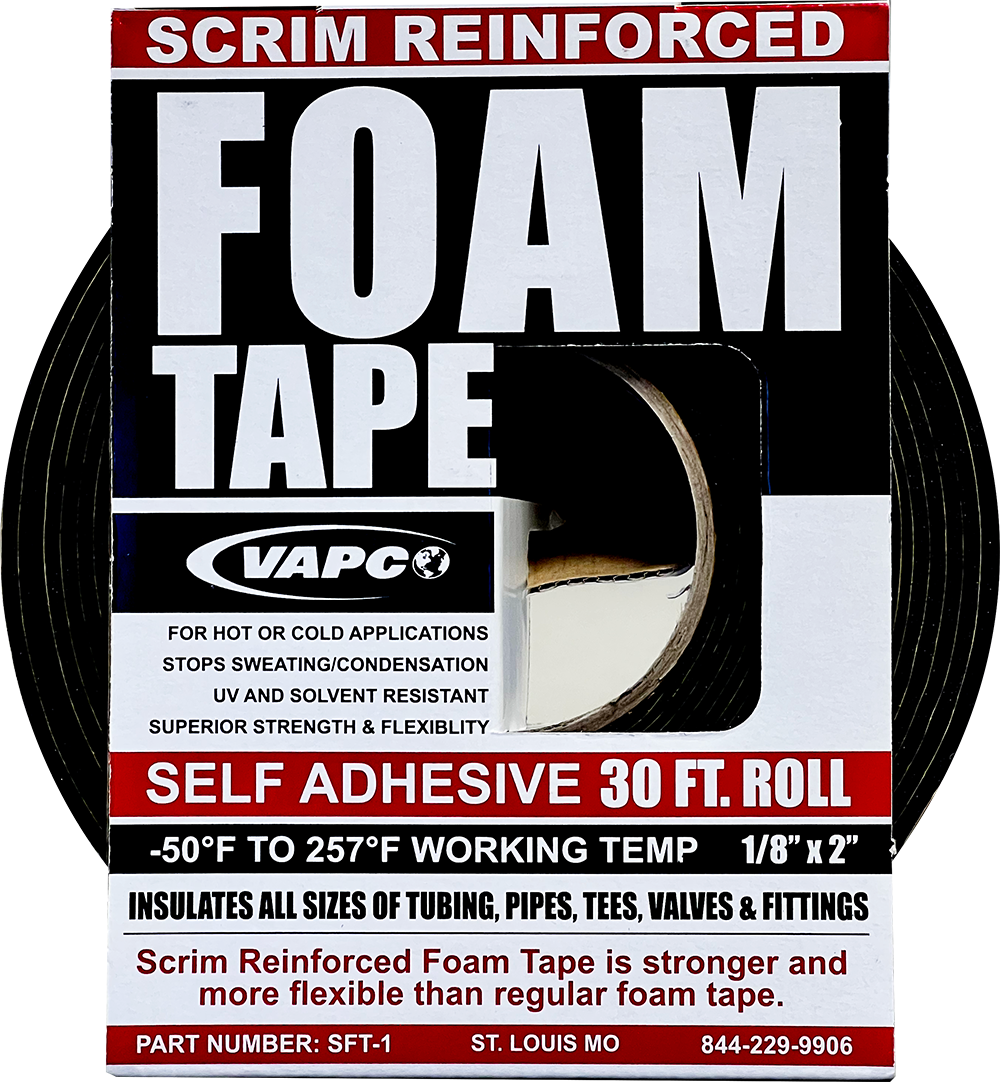

Scrim Reinforced Foam Tape

Elevate Insulation with Scrim Reinforced Foam Tape

Discover the superior performance of our Scrim Reinforced Foam Tape, a premium insulation solution designed to outperform traditional foam tapes. Reinforced with a durable scrim, this tape offers exceptional strength, flexibility, and durability.

Key Features:

- Enhanced Strength and Flexibility: Provides superior performance compared to standard foam tape.

- Temperature Resistance: Withstands temperatures from -50°F to 257°F.

- Moisture, UV, and Solvent Resistance: Protects against environmental factors.

- Self-Adhesive: Ensures easy and secure application.

- Versatile Applications: Ideal for insulating pipes, tubing, tees, valves, and fittings.

Ideal for:

- Insulation: Prevents condensation and energy loss.

- Bonding: Creates a strong and durable bond on various surfaces.

- Vibration Damping: Reduces noise and vibration.

Black Color of Closed Cell Nitrile Butadiene Rubber (NBR) Foam.

- Complies with UL94-HF1, HF2 & HBF1, HBF2b | IEC 60695-22-20 and 60695-11-20 and ISO 9772 and 9773. Meets FMVSS 302 automotive standard and conforms RoHS 2002/95/EC directives.

Ideal for use in thermal, humidity, sound insulation and vibration damping.

Part Number; Size

- SFT-1 2″ x 1/8″ x 30′ 12/cs

Directions:

Effective Installation for Insulation and Bonding

- Prepare Surface: Ensure the surface is clean, dry, and free from debris.

- Apply to Piping: For piping applications, wrap the tape in a spiral around the piping, ensuring edges are butted together to prevent metal exposure. For faster application, overlap edges by 1/4 inch.

- Double Layer Application: For double-layer insulation, overlap the tape by half its width.

Additional Notes:

- Resistance: Scrim Reinforced Foam Tape resists oils, acids, alkalies, most solvents, water, water vapor, rodents,vermin, fungus, and freeze-thaw cycling.

- Odor: The tape may emit a slight odor but is non-contaminating.

- Paintability: Can be painted with most standard paints.

By following these directions, you can effectively install Scrim Reinforced Foam Tape for insulation and bonding applications.

DANGERS & PRECAUTIONS:

Keep out of reach of children. Store in dry cool areas.