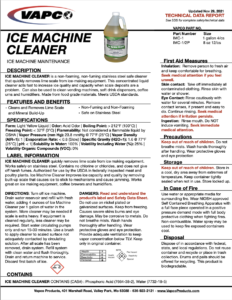

ICE MACHINE CLEANER

Powerful, Low-Foaming Solution for Clean, High-Quality Ice

ICE MACHINE CLEANER has the true highest concentration of Food Grade active ingredients on the market with over 75% phosphoric acid. The water source is the number one issue when maintaining ice machines, hard water contains minerals that drop out of the water during the freezing process and collect all over the system, creating a build up of lime scale. Over time this scale creates diminished returns, eventually leading to jams or shutdown of the equipment. Ice Machine Cleaner is the ideal solution to remove the buildup of scale and return the equipment to a like new state.

Key Features and Benefits:

- Removes Limescale: Restores ice quality and capacity by removing mineral deposits.

- Non-Fuming and Low-Foaming: Safe and easy to use without the hazards of harsh chemicals.

- Safe on Stainless Steel: Protects the integrity of your equipment.

- Versatile Cleaning: Suitable for cleaning vending machines, soft drink dispensers, coffee urns, and humidifiers.

- Food-Grade Ingredients: Safe for use in food processing environments.

- USDA Authorized: Approved for use in federally inspected meat and poultry plants.

Part Number; Size

- IMC-1/2P 8 oz 12/cs

- IMC-1 1 gal 4/cs

Directions:

This product must be used in accordance with the following directions and by professionals only.

- Power Off: Turn off ice machine refrigeration.

- Drain and Refill: Drain the water and refill the system with fresh water.

- Add Cleaner: Add 4 ounces of ICE MACHINE CLEANER per gallon of water. Adjust the amount based on the severity of scale buildup.

- Circulate Water: Start the water circulating pumps only.

- Run for 15-30 Minutes: Allow the cleaning solution to circulate for 15-30 minutes.

- Manual Cleaning: Apply cleaner to heavily scaled areas using a brush.

- Extreme Buildup: In extreme cases additional doses may be necessary.

- Drain and Flush: after the scale has been removed, drain all of the solution and flush thoroughly with fresh water.

- Refill and Power On: Refill the system with fresh water and turn back on the ice machine refrigeration.

- Discard First Batch: Discard the first batch of ice produced after cleaning.

Note: Do not use on galvanized or nickel plated surfaces, for these surfaces and systems use Vapco’s Nickel Guard Ice Machine Cleaner.

*Do not mix with chlorine bleach

DANGERS & PRECAUTIONS

Keep out of reach of children. Do not breathe mists. Wash hands thoroughly after handling. Wear protective gloves and eye protection.

Contact Us

News and Updates

Subscribe on Youtube

Follow Us on Facebook

SDS

⚠️ ICE MACHINE CLEANER SDS – DOWNLOAD

SAFETY DATA SHEET

ICE MACHINE CLEANER

1. Identification & Supplier Details

Product Identification (Section 1.1)

| GHS Product Identifier (Product Name) |

Ice Machine Cleaner |

| Product Number / Brand |

IMC-1, IMC-1/2P / Vapco |

| Recommended Use (1.3) |

Ice machine cleaner |

Supplier Details & Emergency Contact (Section 1.4 & 1.5)

| Supplier Name |

Vapco Products, Inc. |

| Supplier Address |

401 Marshall Road

Valley Park, Missouri 63088, United States |

| Telephone / Fax / Email |

(636) 923-2121 / (636) 923-3002 / [email protected] |

| Emergency Phone Number |

(800) 255-3924 |

2. Hazard Identification & Composition

GHS Classification (Section 2.1)

| GHS Classification (OSHA) |

Corrosive: Eye Damage/Irritation, Cat. 1; Skin Corrosion/Irritation, Cat. 1B |

| Signal Word |

Danger |

| Hazard Statement |

H314: Causes severe skin burns and eye damage. |

| Pictograms |

[Image of GHS Pictogram for Corrosion] |

Precautionary Statements (Section 2.2)

| Category |

Statement(s) |

| Prevention |

P260, P264, P280 (Do not breathe, Wash hands thoroughly, Wear protective gear.) |

| Response (First Aid) |

P301+P330+P331 (IF SWALLOWED: Rinse mouth. Do NOT induce vomiting.)

P303+P361+P353 (IF ON SKIN: Rinse skin/shower. Take off contaminated clothing.)

P305+P351+P338 (IF IN EYES: Rinse cautiously for several minutes.)

P310 (Immediately call a POISON CENTER/doctor.) |

| Storage / Disposal |

P405 (Store locked up.) / P501 (Dispose of contents/container to regulations.) |

Hazardous Components (Section 3.2)

| Chemical Name |

Concentration |

CAS No. |

EC No. |

| Phosphoric acid |

70 – 80 % (weight) |

7664-38-2 |

231-633-2 |

3. Physical & Chemical Properties

Basic Physical and Chemical Properties (Section 9)

| Physical State / Appearance |

Liquid / Clear, Colorless liquid |

| Odor / Odor Threshold |

Acid odor / N/D |

| pH |

<1 (Strongly Acidic) |

| Melting Point/Freezing Point |

<32°F (0°C) |

| Boiling Point or Boiling Range |

>212°F (100°C) |

| Flammability / Flash Point |

Not considered a flammable liquid / N/D |

| Vapor Pressure |

23.8 mmHg at 77°F (25°C) |

| Density and/or Relative Density |

1.6 at 77°F (25°C) |

| Solubility / Evaporation Rate |

Completely soluble in water / <0.8 (Slow) |

4. Stability & Reactivity

Reactivity and Stability (Section 10)

| Reactivity |

May react with strong bases and chemically active metals. May be corrosive to metals. |

| Chemical Stability |

Stable under normal conditions of use. |

| Conditions to Avoid |

Chlorine-liberating material. Do not mix with bases, ammonia, or other cleaning compounds. Direct sunlight, extreme temperatures. |

| Incompatible Materials |

Strong bases and chemically active metals. |

| Hazardous Decomposition Products |

Carbon oxide(s), nitrogen oxide(s), phosphorous oxide(s). |

5. Toxicological Information

Information on Toxicological Effects (Section 11)

| Skin Corrosion/Irritation |

Causes severe burns, prolonged contact will destroy tissue. |

| Serious Eye Damage/Irritation |

Causes severe burns, irritation, redness, and may result in loss of sight. |

| Respiratory Sensitization |

May cause irritation (possible severe), chemical burns, upper respiratory damage, and pulmonary edema. |

| STOT – Single Exposure |

Causes severe burns, prolonged contact will destroy tissue. |

| Chronic/Repeated Exposure Symptoms |

Dermatitis, upper respiratory damage, chemical burns, pulmonary edema, potential loss of sight. |

| Medical Condition Aggravated |

Asthma, bronchitis, emphysema and other lung diseases and chronic nose, sinus or throat conditions. Existing skin disorders. |

6. First-Aid Measures

Description of Necessary First-Aid Measures (Section 4.1)

| General Advice |

Never give anything by mouth to an unconscious person. If you feel unwell, seek medical advice (show the label where possible). |

| If Inhaled |

Remove person to fresh air. Keep comfortable for breathing. Get medical advice/attention. |

| In Case of Skin Contact |

Immediately drench affected area with water for at least 15 minutes. Remove contaminated clothing immediately. Obtain medical attention if irritation develops or persists. |

| In Case of Eye Contact |

Immediately rinse with water for at least 15 minutes. Remove contact lenses, if present and easy to do. Continue rinsing. Obtain medical attention if irritation develops or persists. |

| If Swallowed |

Rinse mouth. Do NOT induce vomiting. Obtain medical attention. |

Most Important Symptoms/Effects (Section 4.2): Harmful if inhaled. Causes serious eye and skin irritation/burns. Dermatitis and permanent eye damage are possible.

Immediate Medical Attention (Section 4.3): Get medical advice/attention. The absence of visible signs or symptoms of burns does not reliably exclude the presence of actual tissue damage.

7. Fire-Fighting & Accidental Release Measures

Fire-Fighting Measures (Section 5)

| Suitable Extinguishing Media |

Water spray, fog, carbon dioxide ($text{CO}_2$), alcohol-resistant foam, dry chemical, or sand. |

| Specific Hazards (Reactivity) |

May be corrosive to metals and reactive to strong bases. Increased risk of fire or explosion. |

| Protection During Firefighting |

Do not enter fire area without proper protective equipment. Wear NIOSH-approved Self-Contained Breathing Apparatus (SCBA) with full face piece and full body protective clothing. |

Accidental Release Measures (Section 6)

| Personal Precautions/PPE |

Do not get in eyes, on skin, or on clothing. Do not breathe vapors. Keep away from heat/ignition sources. Use appropriate PPE (Section 8). |

| Containment & Clean Up Methods |

Ventilate the area. Contain spills with dikes or absorbents to prevent entry into sewers. Isolate spill/leak area in all directions. Take up liquid spill into absorbent material and transfer to a suitable container for disposal. |

8. Handling, Storage & PPE

Precautions for Safe Handling (Section 7.1)

| Precautions for Safe Handling |

Do not handle until all safety precautions have been read and understood. Avoid contact with skin, eyes and clothing. Wash hands before eating, drinking or smoking. |

| Additional Hazards When Processed |

Do not pressurize, cut, or weld containers. Pressurized container: May burst if heated. Do not pierce or burn, even after use. |

Conditions for Safe Storage (Section 7.2)

| Storage Conditions |

Store in a dry, cool, well-ventilated place. Store locked up/in a secure area. Protect from sunlight. Do not expose to temperatures exceeding 50°C/122°F. |

| Incompatible Materials |

Strong bases and chemically active metals. |

Exposure Controls and PPE (Section 8)

| Exposure Limit (Phosphoric acid, 7664-38-2) |

Value / Source |

| TWA (Inhalation) |

1 $text{mg}/text{m}^{3}$ |

AU, EU, US (OSHA, Cal/OSHA, NIOSH) |

| STEL (Inhalation) |

2 – 3 $text{mg}/text{m}^{3}$ |

AU, EU, US (Cal/OSHA, NIOSH) |

| Eye/Face Protection |

Chemical safety goggles. |

| Skin/Body Protection |

Wear protective gloves, clothing, and fire/flame resistant/retardant clothing. Chemical resistant materials required. |

| Respiratory Protection |

Use a NIOSH-approved Self-Containing Breathing Apparatus whenever exposure may exceed established OELs. |

9. Transport & Regulatory Information

Transport Information (Section 14)

| Regulation |

UN Number |

Class |

Packing Group |

Proper Shipping Name |

| DOT (US) / IMDG / IATA |

UN1805 |

8 (Corrosive) |

III |

Phosphoric acid solution |

Regulatory Information (Section 15)

| Components Listed |

Phosphoric acid (CAS: 7664-38-2) is listed on: Massachusetts Right To Know, Massachusetts TURA, New Jersey Right To Know, Pennsylvania Right To Know, and US EPA TSCA public inventory. |

10. Disposal & Ecological Information

Ecological Information (Section 12)

| Toxicity |

No data available. |

| Persistence and Degradability |

This product is biodegradable. |

| Bioaccumulative Potential / Mobility in Soil |

Not expected to bioaccumulate / Mobile in soil. |

Disposal Considerations (Section 13)

| Product Disposal / Waste Treatment |

Dispose of contents/container in accordance with local, regional, national, and international regulations. Hazardous waste number(s): D002 (Corrosivity). Check the pH of waste. |

| Other Disposal Recommendations |

Container may remain hazardous when empty. Do not puncture or incinerate container. Waste should not be disposed of untreated to the sewer unless fully compliant. |

11. Disclaimer & Preparation Information

Preparation Information (Section 16.2)

| Prepared by |

Jessica Wilson |

| Date Prepared |

3-4-2025 |

Disclaimer (Section 16.1):

To the best of our knowledge, information contained herein is accurate. However there is no assumption of liability for the accuracy or completeness of the information contained herein. Final determination of suitability of any material is the sole responsibility of the user. The information contained in this SDS was obtained from current and reliable sources; however, the data is provided without warranty, expressed or implied, regarding its correctness or accuracy. The user is responsible for full compliance with various government agency regulations. No warranty, expressed or inferred, regarding the product described in this SDS shall be created or inferred by any statement in this SDS.

Key: N/A = Not applicable; N/D = Not determined