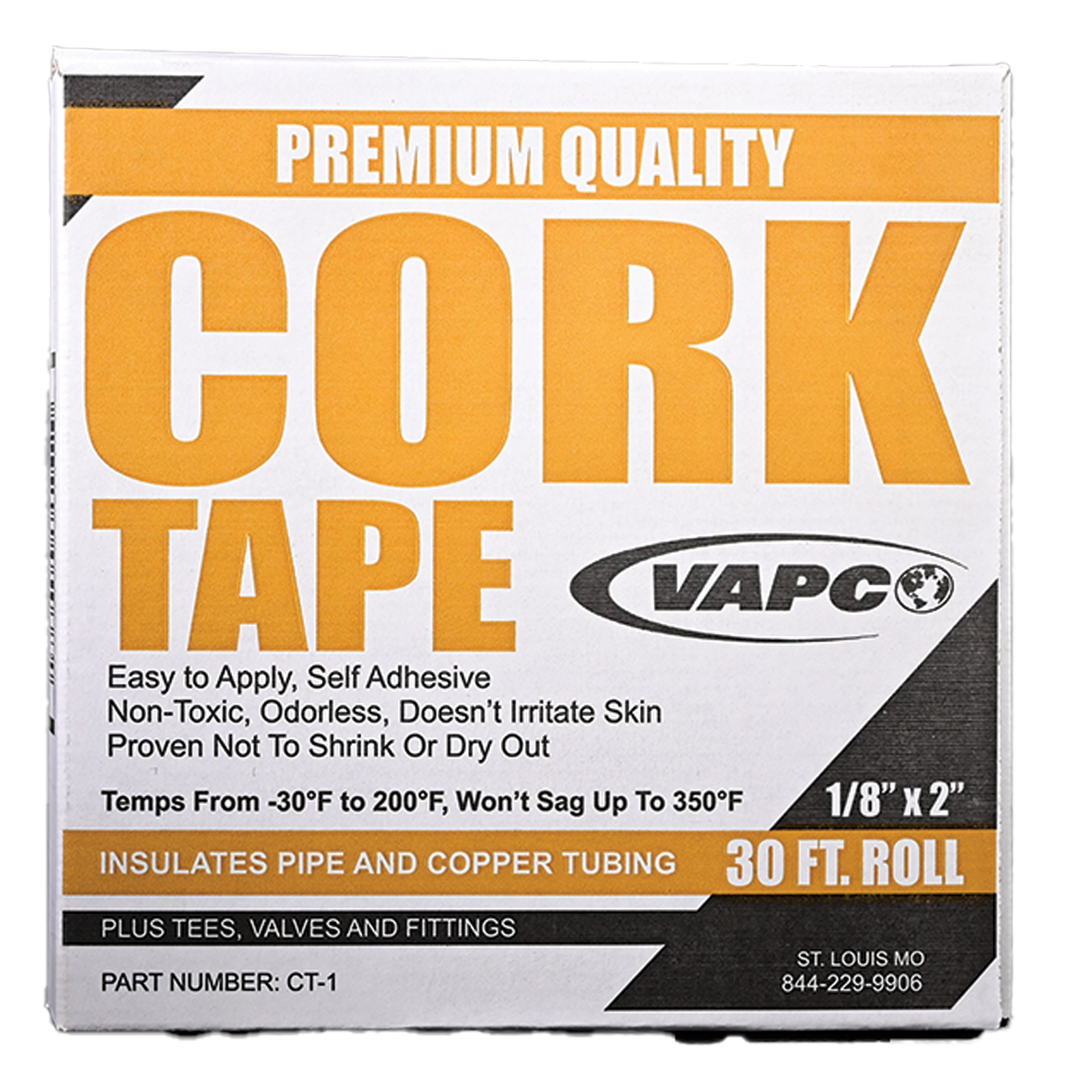

CORK TAPE

Versatile Insulation and Soundproofing Solution

CORK TAPE is a high-performance insulation and soundproofing material made from ground cork specifically created for the HVACR industry. It effectively prevents condensation on cold pipes and surfaces, making it ideal for air conditioning systems, freezers, commercial refrigeration, and other applications where condensation is a concern. Cork Tape is a great insulator in extreme temperatures: maximum service temperature up to 350°F and still effective as low as -30°F, (should be applied to pipes at less than 200°F to avoid installation issues). 2″ x 1/8″ x 30′ and comes in a case of 12.

Key Features and Benefits:

- Versatile Applications: Ideal for insulation, soundproofing, and condensation prevention.

- Self-Adhesive: No additional adhesives required for easy application.

- Wide Temperature Range: Suitable for both hot and cold applications (-20°F to 180°F).

- Excellent Adhesion: Bonds securely to various surfaces, including metal, glass, plastic, rubber, and painted surfaces.

- Durable and Long-Lasting: Does not shrink, dry out, or pull away from surfaces.

- Non-Toxic and Odorless: Safe for use in various environments.

- Soundproofing Properties: Reduces noise transmission for improved acoustics.

- High Insulation Value: Provides a single layer insulation value of 0.43 (K factor).

- Heat-Resistant: Maintains its properties at temperatures up to 350°F.

Ideal for:

- Air conditioning systems

- Freezers

- Commercial refrigeration

- Pipe insulation

- Soundproofing applications

Part Number; Size

- CT-1 2″ x 1/8″ x 30′ – 12/cs

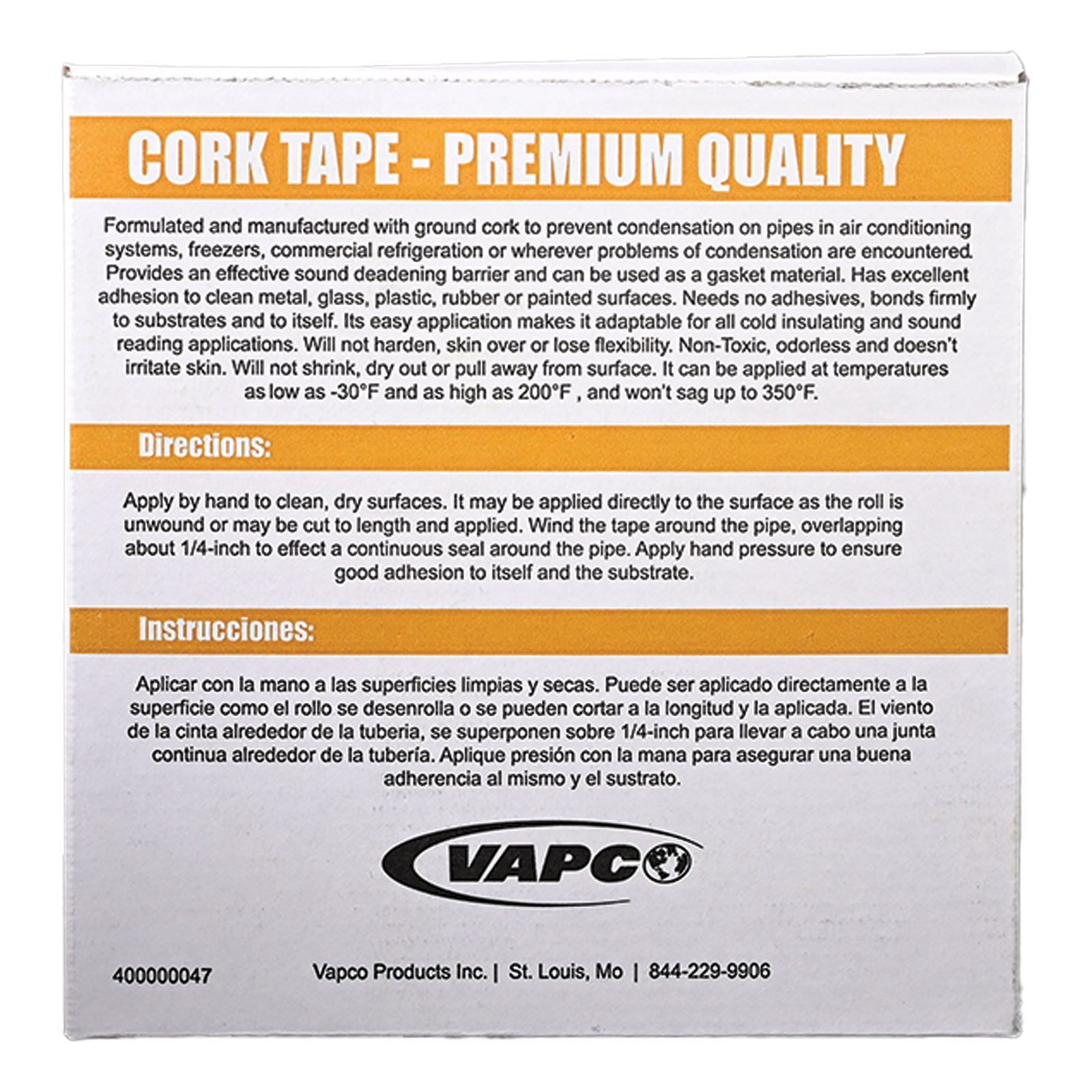

Directions:

- Clean Surface: Ensure the surface is clean and dry before applying CORK TAPE.

- Measure and Cut: Measure the required length and cut the tape accordingly.

- Direct Application: Apply the tape directly to the surface.

- Wrap and Overlap: Wind the tape around the pipe, overlapping by approximately 1/4 inch to create a continuous seal.

- Apply Pressure: Press firmly to ensure secure adhesion.

One layer of tape will protect under most conditions: in extremes temperatures or high humidity environments, additional layers may be added.