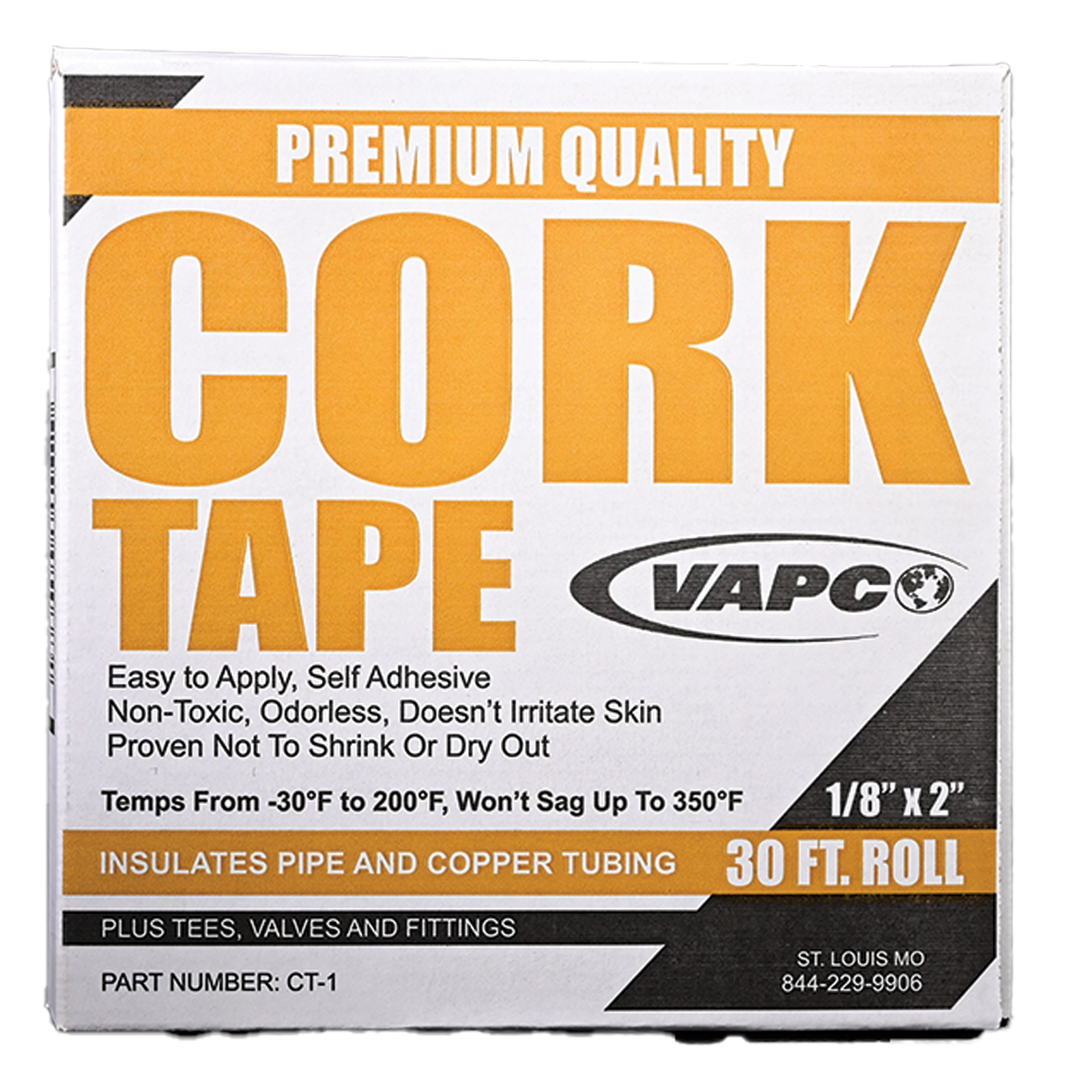

CORK TAPE

Versatile Insulation and Soundproofing Solution

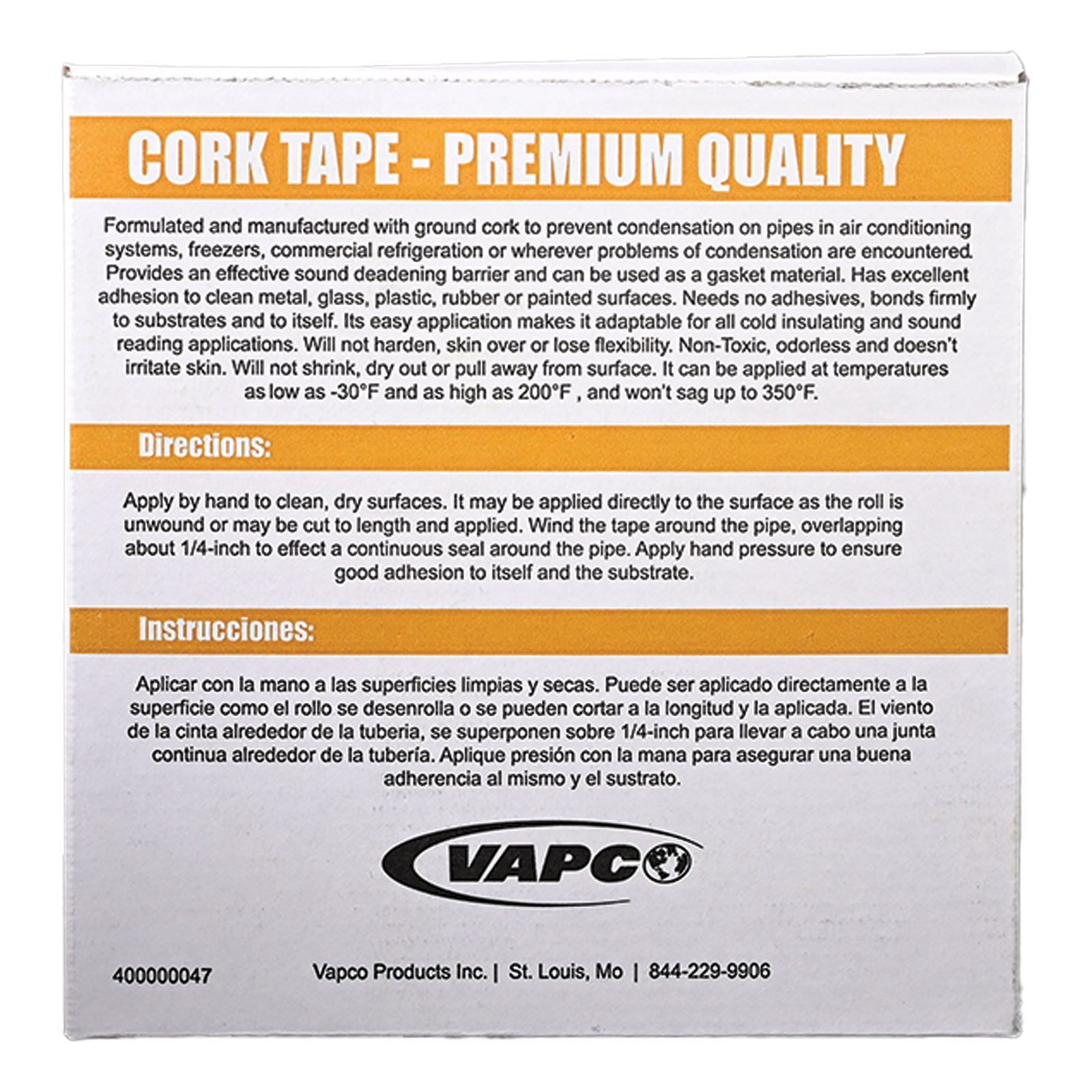

CORK TAPE is a high-performance insulation and soundproofing material made from ground cork specifically created for the HVACR industry. It effectively prevents condensation on cold pipes and surfaces, making it ideal for air conditioning systems, freezers, commercial refrigeration, and other applications where condensation is a concern. Cork Tape is a great insulator in extreme temperatures: maximum service temperature up to 350°F and still effective as low as -30°F, (should be applied to pipes at less than 200°F to avoid installation issues). 2″ x 1/8″ x 30′ and comes in a case of 12.

Key Features and Benefits:

- Versatile Applications: Ideal for insulation, soundproofing, and condensation prevention.

- Self-Adhesive: No additional adhesives required for easy application.

- Wide Temperature Range: Suitable for both hot and cold applications (-20°F to 180°F).

- Excellent Adhesion: Bonds securely to various surfaces, including metal, glass, plastic, rubber, and painted surfaces.

- Durable and Long-Lasting: Does not shrink, dry out, or pull away from surfaces.

- Non-Toxic and Odorless: Safe for use in various environments.

- Soundproofing Properties: Reduces noise transmission for improved acoustics.

- High Insulation Value: Provides a single layer insulation value of 0.43 (K factor).

- Heat-Resistant: Maintains its properties at temperatures up to 350°F.

Ideal for:

- Air conditioning systems

- Freezers

- Commercial refrigeration

- Pipe insulation

- Soundproofing applications

Part Number; Size

- CT-1 2″ x 1/8″ x 30′ – 12/cs

Directions:

- Clean Surface: Ensure the surface is clean and dry before applying CORK TAPE.

- Measure and Cut: Measure the required length and cut the tape accordingly.

- Direct Application: Apply the tape directly to the surface.

- Wrap and Overlap: Wind the tape around the pipe, overlapping by approximately 1/4 inch to create a continuous seal.

- Apply Pressure: Press firmly to ensure secure adhesion.

One layer of tape will protect under most conditions: in extremes temperatures or high humidity environments, additional layers may be added.

Contact Us

News and Updates

Subscribe on Youtube

Follow Us on Facebook

SDS

⚠️ CORK TAPE SDS – DOWNLOAD

SAFETY DATA SHEET

Identification & Supplier Details

SECTION 1: IDENTIFICATION

| 1.1 Product Identifier & Brand |

| Product Name |

Cork Tape |

| Product Number |

CT-1 |

| Brand |

Vapco |

| Recommended Use |

Cork insulation tape |

| 1.4 Supplier Details |

| Name |

Vapco Products, Inc. |

| Address |

401 Marshall Road, Valley Park, Missouri 63088, United States |

| Telephone |

(636) 923-2121 |

| Fax |

(636) 923-3002 |

| Email |

[email protected] |

| Emergency Phone Number |

(800) 255-3924 |

Hazard Identification & Composition

SECTION 2: HAZARD IDENTIFICATION & SECTION 3: COMPOSITION

| 2.1 & 2.2 Hazard Classification & GHS Label Elements |

| GHS Classification |

Not a hazardous substance or mixture (OSHA 29 CFR 1910.1200, 2012). |

| GHS Label Elements |

Not a hazardous substance or mixture. |

| Other Hazards |

None known. |

| 3.2 Mixtures / Hazardous Components |

| Hazardous Ingredients |

Does not contain any hazardous ingredient at or above reportable levels as defined by OSHA. |

First-Aid Measures

SECTION 4: FIRST-AID MEASURES

| Exposure Route |

First-Aid Description |

| General Advice |

Never give anything by mouth to an unconscious person. If you feel unwell, seek medical advice (show the label where possible). |

| If Inhaled |

Remove the exposed person to fresh air. Keep at rest in a position comfortable for breathing. Get medical advice/attention. |

| In Case of Skin Contact |

Immediately drench affected area with water for at least 15 minutes. Remove contaminated clothing immediately. Obtain medical attention if irritation develops or persists. |

| In Case of Eye Contact |

Immediately rinse with water for at least 15 minutes. Remove contact lenses, if present and easy to do. Obtain medical attention if irritation develops or persists. |

| If Swallowed |

Rinse mouth. Do NOT induce vomiting. Obtain medical attention. |

| Most Important Symptoms / Effects |

None known. |

| Immediate Medical Attention |

If exposed or concerned, get medical advice and attention. Have product container or label at hand. |

Fire-Fighting & Accidental Release Measures

SECTION 5: FIRE-FIGHTING MEASURES & SECTION 6: ACCIDENTAL RELEASE MEASURES

| 5.1 Suitable Extinguishing Media |

| Media |

Water spray, fog, carbon dioxide (CO2), alcohol-resistant foam, dry chemical, or sand. Use appropriate media for surrounding fire. |

| Specific Hazards |

None known. |

| Special Protective Actions |

Do not enter fire area without proper protective equipment, including respiratory protection. Use NIOSH-approved SCBA. |

| 6.1 Personal Precautions & 6.3 Methods for Containment and Cleaning Up |

| Personal Precautions |

Do not get in eyes, on skin, or on clothing. Keep away from heat, hot surfaces, sparks, open flames. No smoking. |

| Spill Clean Up (Small & Large) |

Repackage uncontaminated tape. Dispose of contaminated or unusable tape. |

Handling, Storage & PPE

SECTION 7: HANDLING AND STORAGE & SECTION 8: EXPOSURE CONTROLS / PPE

| 7.1 & 7.2 Precautions for Safe Handling and Storage |

| Handling Precautions |

Prevent high temperature exposure. |

| Storage Conditions |

Store in a dry, cool place. Keep only in the original container away from ignition sources. Prevent high temperature exposure. |

| 8.2 Appropriate Engineering Controls |

| Engineering Controls |

Emergency eye wash fountains and safety showers should be available. Ensure adequate ventilation. Use explosion-proof equipment. |

| 8.3 Individual Protection Measures (PPE) |

| Eye/Face Protection |

Not required. |

| Skin Protection |

Not required. |

| Respiratory Protection |

Not required under normal conditions of use. |

Physical & Chemical Properties

SECTION 9: PHYSICAL AND CHEMICAL PROPERTIES

| Property |

Value |

| Physical State |

Solid |

| Appearance |

Soft, pliable pressure sensitive material |

| Odor |

N/A |

| Odor Threshold |

N/S |

| Melting Point/Freezing Point |

$400^circ F$ |

| Boiling Point/Range |

N/A |

| Flash Point |

$450^circ F$ |

| Flammability (Solid, Gas) |

N/A |

| Lower and Upper Explosion/Flammability Limit |

N/A |

| Auto-Ignition Temperature |

N/A |

| Decomposition Temperature |

N/A |

| pH |

N/A |

| Solubility |

None |

| Density and/or Relative Density |

0.76 |

| Vapor Pressure |

N/A |

| Relative Vapor Density |

N/A |

| Evaporation Rate |

N/A |

| Kinematic Viscosity |

N/A |

| Partition Coefficient n-octanol/water (log value) |

N/A |

Stability & Reactivity

SECTION 10: STABILITY AND REACTIVITY

| Reactivity |

None known. |

| Chemical Stability |

Stable under normal conditions of use. |

| Possibility of Hazardous Reactions |

None known. |

| Conditions to Avoid |

Extremely high temperature exposure. |

| Incompatible Materials |

Oxygen supplying chemicals and contact with acid clays at elevated temperatures. |

| Hazardous Decomposition Products |

None known. |

Toxicological Information

SECTION 11: TOXICOLOGICAL INFORMATION

| Effect / Endpoint |

Information |

| Acute Toxicity |

No data available. |

| Skin Corrosion/Irritation |

No data available. |

| Serious Eye Damage/Irritation |

No data available. |

| Respiratory or Skin Sensitization |

No data available. |

| Germ Cell Mutagenicity |

No data available. |

| Carcinogenicity |

No data available. |

| Reproductive Toxicity |

No data available. |

| STOT – Single Exposure |

No data available. |

| STOT – Repeated Exposure |

No data available. |

| Aspiration Hazard |

No data available. |

Disposal & Ecological Information

SECTION 12: ECOLOGICAL INFORMATION & SECTION 13: DISPOSAL CONSIDERATIONS

| 12.1 Toxicity / Ecological Data |

| Toxicity |

No data available. |

| 13.1 Disposal Methods |

| Product Disposal |

Bury tape in an approved land fill site. Dispose of in accordance with all local, state, and federal regulations. |

Transport & Regulatory Information

SECTION 14: TRANSPORT INFORMATION & SECTION 15: REGULATORY INFORMATION

| 14.1 UN Number / Transport Status |

| DOT (US) |

Not dangerous goods |

| IMDG |

Not dangerous goods |

| IATA |

Not dangerous goods |

| 15.1 Safety, Health and Environmental Regulations |

| California Proposition 65 Chemicals |

None |

Disclaimer & Preparation Information

SECTION 16: OTHER INFORMATION

| Legend |

| Abbreviations |

N/A = Not applicable; N/D = Not determined; N/S = Not specified |

| 16.1 Further Information / Disclaimer |

| To the best of our knowledge, information contained herein is accurate. However there is no assumption of liability for the accuracy or completeness of the information contained herein. Final determination of suitability of any material is the sole responsibility of the user. The information contained in this SDS was obtained from current and reliable sources; however, the data is provided without warranty, expressed or implied, regarding its correctness or accuracy. No warranty, expressed or inferred, regarding the product described in this SDS shall be created or inferred by any statement in this SDS. The user is responsible for full compliance with all local, regional, national, and international regulations. |

| 16.2 Preparation Information |

| Prepared By |

Jessica Wilson |

| Date Prepared |

10/14/2025 |