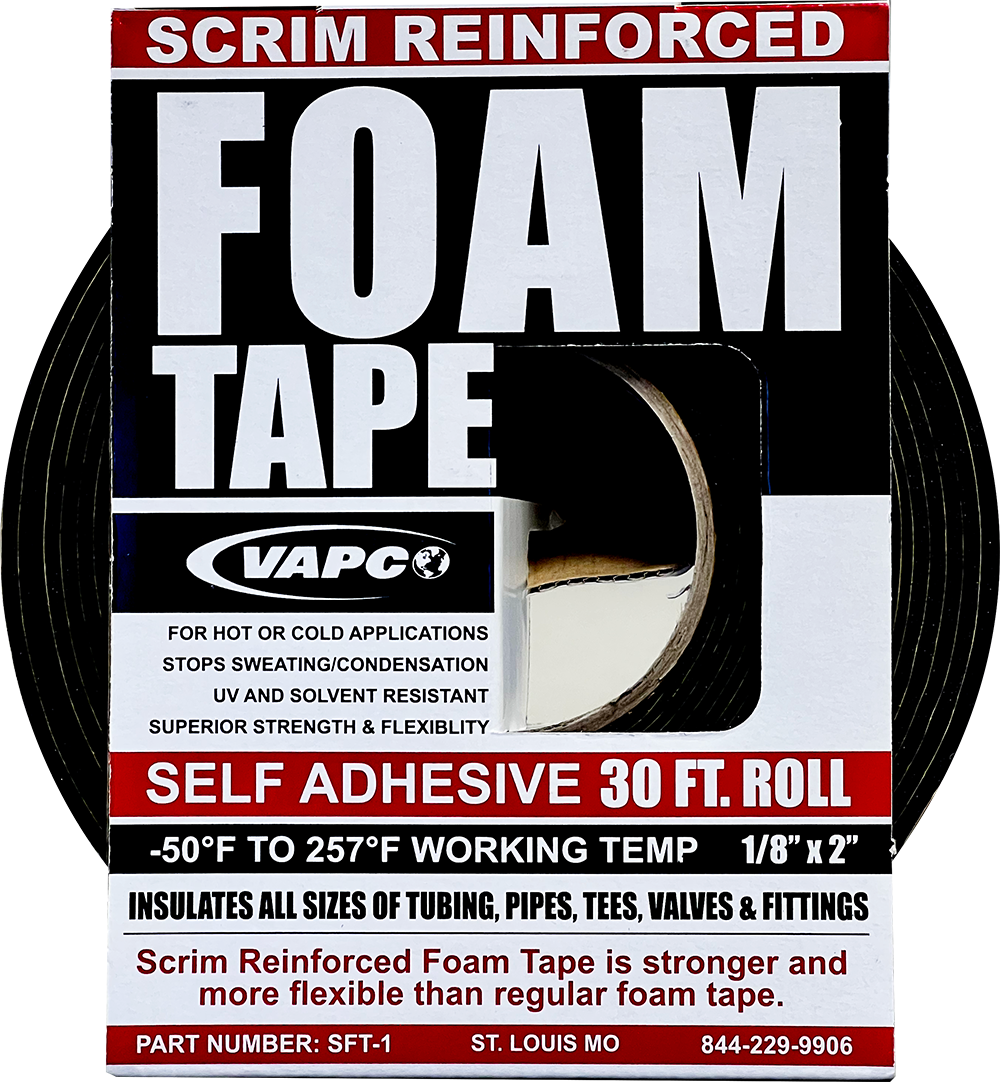

SCRIM REINFORCED FOAM TAPE

High-Performance Insulation and Bonding Solution

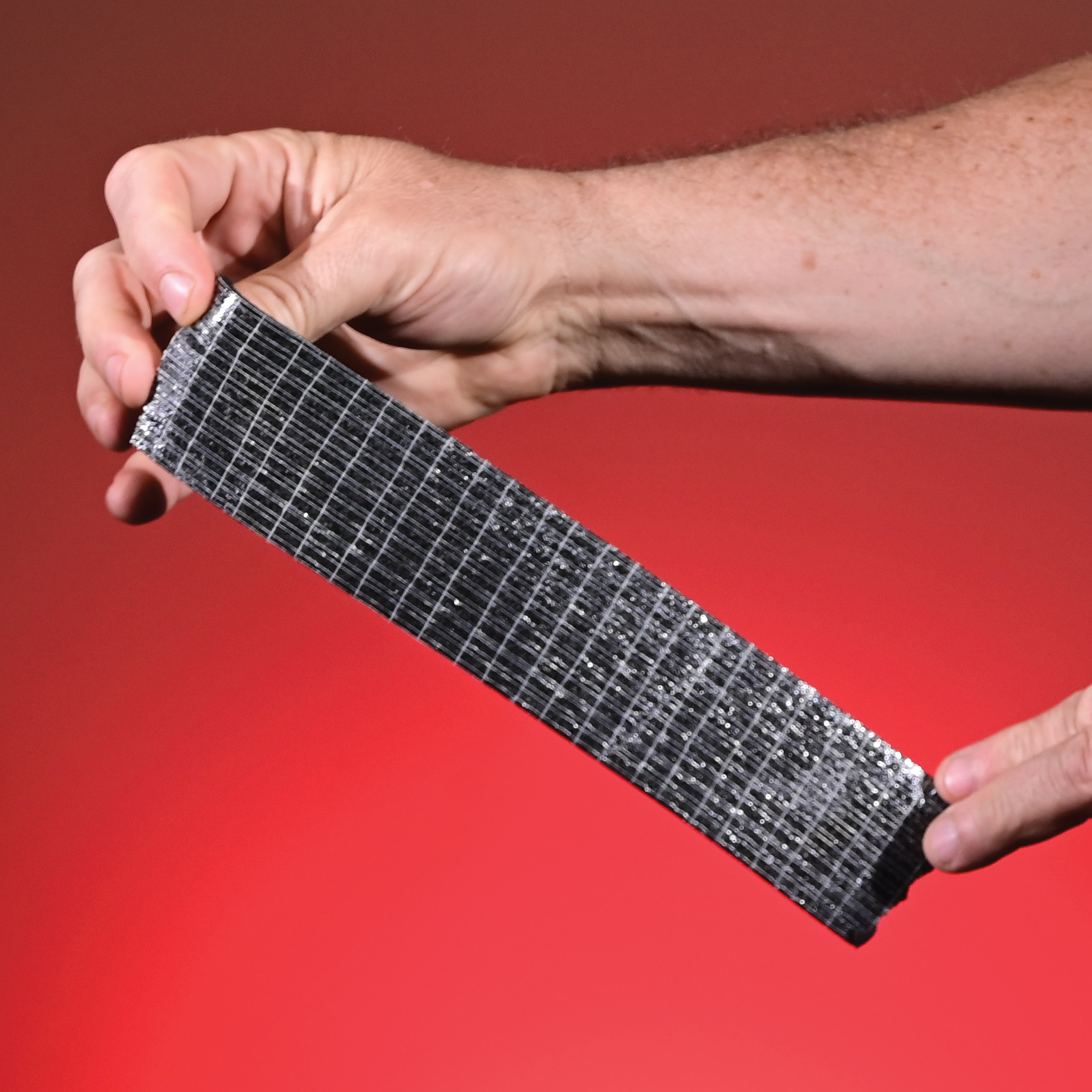

SCRIM REINFORCED FOAM TAPE is a premium insulation tape designed to provide exceptional performance and durability. The inclusion of an internal scrim provides significant advantages over standard foam tapes, allowing for use in more harsh environments. Highly resistant to oils, acids, alkalies, and most solvents, as well as water, water vapor, UV exposure, and freeze-thaw cycling. It is pest resistant and actively inhibits the growth of fungus, mold and mildew. Engineered with a closed-cell Nitrile Rubber (NBR) foam backing and a scrim-reinforced acrylic adhesive, this tape offers superior mechanical strength and dimensional stability.

Key Features and Benefits:

- Superior Insulation: Effectively insulates hot and cold pipes, tubing, and other surfaces.

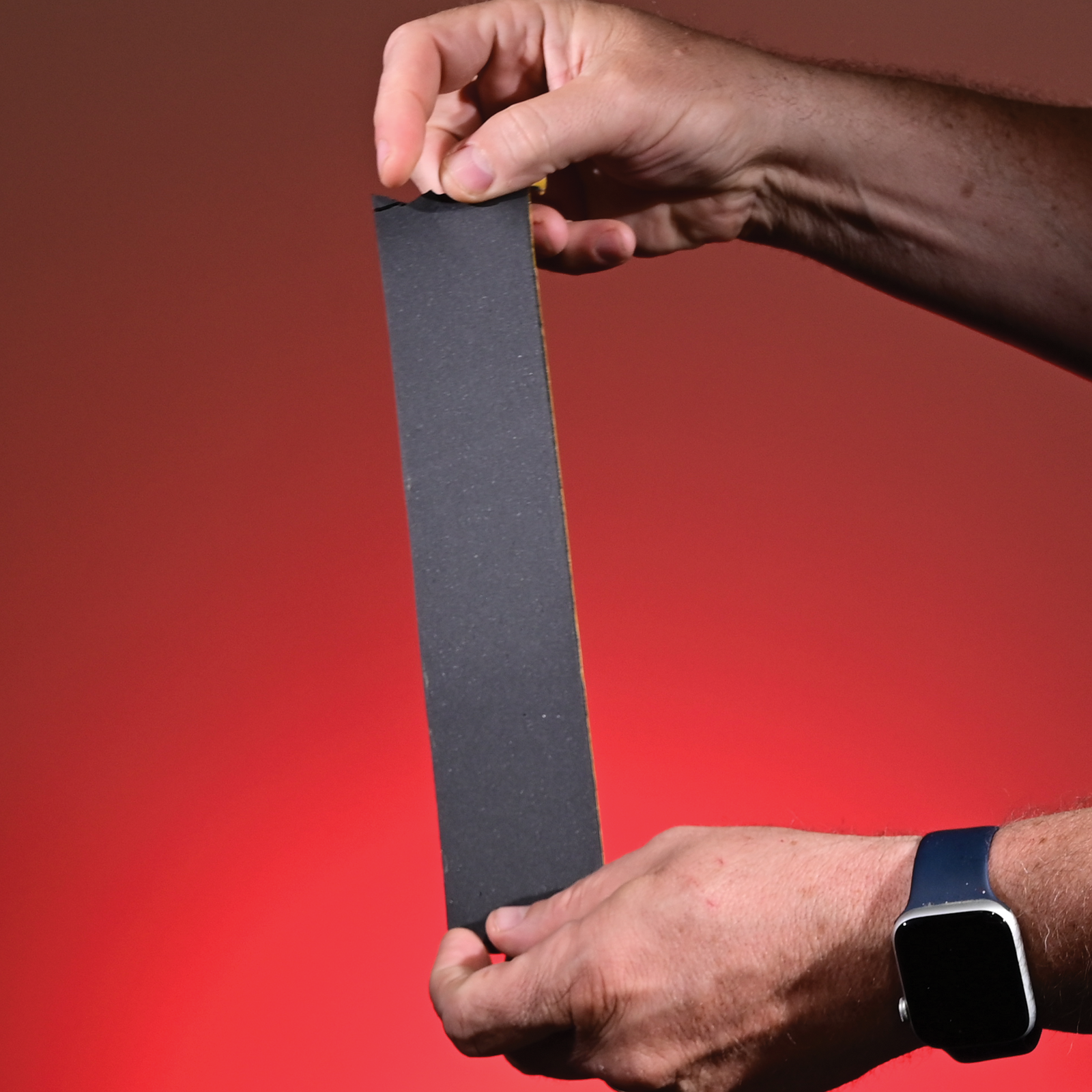

- Flexible and Conformable: With an ultimate elongation of 200% (ASTM-D 412), the tape easily wraps pipes, fittings, and irregular surfaces for a complete seal.

- Temperature Resistance: Withstands temperatures from -50°F to 257°F – ASTM-D 3575.

- Environmental Resistant: Highly resistant to oils, acids, alkalies, and most solvents, as well as water, water vapor, UV exposure, and freeze-thaw cycling.

- Self-Adhesive: Provides easy and secure application with an easy peel backing.

- Compatible Surfaces: Adheres reliable to clean metals, glass, plastic, and painted surfaces.

- Acoustic Dampening: Effective sounds deadening and vibration barrier – reduces noise transmission from piping and equipment.

- Seals Gap: Easily fills and seals small gaps, joints, and irregular surfaces.

- Exceeds Industry Standards: Fire Safety Compliance – meets multiple standards including FMVSS 3012, DIN 4102 (B1), and UL94 (HF-1, HF-2, HBF-1, HBF-2)

- Eco-Friendly Composition: The product is CFC FREE and does not contain solvents, heavy metals, or benzene.

- Paintable: Can be painted to match surrounding surfaces.

Part Number; Size

- SFT-1 2″ x 1/8″ x 30′ – 12/cs

Directions

For best results and to ensure a long-lasting, secure bond:

- Prepare the Surface: Ensure the pipe or fitting surface is clean, dry, and free of moisture, oil, or rust.

- Initial Wrap: Remove the release paper and begin spirally wrapping the tape around the piping.

- Optimal Overlap: For maximum efficiency and a continuous seal, wrap the tape with approximately 50% overlap.

- Do Not Stretch: Apply the tape by pressing it firmly into place, avoiding excessive stretching.

- Insulating Fittings: For complex surfaces like valves and tees, cut small sections of tape to press and mold into place until the metal is completely covered.

- Build Thickness: For areas with extreme conditions, apply additional layers of tape to reach the required insulation thickness.

- Final Securement: Press down firmly over the entire tape surface to ensure the pressure-sensitive adhesive has fully adhered.

TECHNICAL DATA:

- Density : 50 – 70 Kg/m3 (ISO 845)

- Tensile Strength : 3,20 Kg/cm2 (ASTM-D 412)

- Tearing Strength : 1,60 KN/m (ASTM-D 412)

- Vapor Diffusion Factor : > 7000

- Ultimate Elongation : % 200 (ASTM-D 412)

- Water Absorption : % 5 (ASTM-D 1056)

- Working Temperature : -50°F to 257°F. (ASTM-D 3575)

- Fire Resistance (Passed) : FMSS 3012, B1, (DIN 4102)

- UL94 HF-1 HF-2, HBF-1, HBF-2 INTERTEK: TURT19003302

- Color : Black

Contact Us

News and Updates

Subscribe on Youtube

Follow Us on Facebook

SDS

⚠️ FOAM TAPE SCRIM REINFORCED SDS – DOWNLOAD

1. Identification & Supplier Details

| Product Name |

Foam Tape, Scrim Reinforced |

| Product Number |

SFT-1 |

| Brand |

Vapco |

| Recommended Use |

Insulating, woven foam tape |

| Supplier |

Vapco Products, Inc.

401 Marshall Road

Valley Park, Missouri 63088 United States |

| Contact Information |

Phone: (636) 923-2121 | Fax: (636) 923-3002 | Email: [email protected] |

| Emergency Phone |

(800) 255-3924 |

2. Hazard Identification & Composition

| GHS Classification |

Not a hazardous substance or mixture (OSHA 29 CFR 1910.1200) |

| Label Elements |

None required |

| Other Hazards |

None identified |

| Hazardous Components |

| Does not contain any hazardous ingredients at or above reportable levels as defined by OSHA (29 CFR 1910.1200). |

3. Physical & Chemical Properties

| Physical State: Solid |

Appearance: Foam tape |

| Color: Black with yellow liner |

Odor: Light characteristic |

| pH: N/A |

Density: 60 kg/m3 |

| Solubility: Very low |

Boiling Point: N/D |

| Flash Point: N/D |

Evaporation Rate: N/D |

4. Stability & Reactivity

| Reactivity |

None known under normal conditions of use. |

| Chemical Stability |

Stable under normal conditions of use. |

| Conditions to Avoid |

None known. |

| Incompatible Materials |

None known under normal conditions of use. |

| Hazardous Decomp. |

None known under normal conditions of use. |

5. Toxicological Information

| Acute Toxicity |

Low risk due to material characteristics; no specific data on ingestion/inhalation. |

| Skin/Eye Irritation |

None known; hypersensitivity may occur during skin contact. |

| Carcinogenicity |

Not classified. |

| Other Effects |

Not classified for mutagenicity, reproductive toxicity, or STOT. |

6. First-Aid Measures

| Inhalation |

Not applicable. |

| Skin Contact |

If irritation or hypersensitivity occurs, seek medical advice. |

| Eye Contact |

Rinse with water for 15 minutes. Remove contact lenses if possible. Seek medical attention if irritation persists. |

| Ingestion |

Rinse mouth. Do NOT induce vomiting. Obtain medical attention. |

7. Fire-Fighting & Accidental Release Measures

| Extinguishing Media |

Water spray, fog, CO2, alcohol-resistant foam, dry chemical, or sand. |

| Firefighting Gear |

Wear NIOSH-approved Self-Contained Breathing Apparatus (SCBA) and full protective clothing. |

| Spill Procedures |

Product is an insoluble solid; accidental spillage is not expected. |

| Personal Precautions |

Eliminate ignition sources. Do not get in eyes or on skin. Ventilate area. |

8. Handling, Storage & PPE

| Safe Handling |

Avoid contact with eyes and skin. Wash hands before eating or smoking. Keep out of reach of children. |

| Storage |

Store in a dry, cool, well-ventilated place. Protect from direct sunlight and ignition sources. Keep in original container. |

| Eye Protection |

Chemical safety goggles. |

| Skin/Body Protection |

Wear protective gloves and fire-resistant clothing. |

| Respiratory |

Use NIOSH-approved SCBA if exposure exceeds established limits. |

9. Transport & Regulatory Information

| DOT (US) |

Not dangerous goods |

| IMDG / IATA |

Not dangerous goods |

| Regulatory Status |

Not applicable to this product. |

10. Disposal & Ecological Information

| Ecotoxicity |

None known. |

| Persistence |

Not determined. |

| Disposal Methods |

Dispose of contents/container in accordance with local, regional, national, and international regulations. |

11. Disclaimer & Preparation Information

| Prepared By |

Jessica Wilson |

| Date Prepared |

8-20-2025 |

| Disclaimer |

The information contained herein is accurate to the best of our knowledge. However, no warranty is expressed or implied. Final determination of suitability is the sole responsibility of the user. |