Aggressive Tack High Solids HVAC Contact Adhesive:

Mean Green MGA-1

Performance Engineered for Speed and Strength

Mean Green is Vapco’s premium Aggressive Tack High Solids Contact Adhesive designed for maximum application speed and superior yield on the job site.

The Aggressive Solvent Advantage: This formula employs a powerful Acetone/Heptane solvent system that delivers near-instant tack and a final bond that aggressively resists heat, cold, and moisture. This formula is deliberately non-Methylene Chloride (NO MECL), ensuring a high-performance system free from restricted solvents.

Highest Solids Content: Mean Green boasts the extremely high solids content, which means less solvent soaks into porous duct liner and more resin remains on the surface. By choosing this Aggressive Tack High Solids HVAC Contact Adhesive, contractors ensure maximum bond strength and coverage area, translating directly to maximum yield and cost savings.

Visual Quality Control: The adhesive’s signature Green color provides visual confirmation of full coverage on substrates. This visual assurance simplifies inspection and prevents costly rework.

| KEY FEATURE / SPECIFICATION | TRADE BENEFIT / RESULT |

|---|---|

| Low VOC Content 40% – 50% | While failing the 40% restriction in California, Mean Green does meet the standards of every other state for one of the most high strength aerosol spray adhesives on the market. |

| Non-Chlorinated Solvent Base | Methylene Chloride-Free: Delivers high performance without using restricted, harmful chlorinated solvents. |

| Quick Flash-Off (Instant Tack) | Rapid Installation: Fast-evaporating solvents minimize waiting time, accelerating project completion and improving crew efficiency. |

| Versatile Applications | Forms strong bonds on Wood, Laminates, Vinyl, Fabric, Felt, Leather, Metals, in addition to Fiberglass, Bubble Wrap, Bubble Foil. |

| Competitive Thermal Stability -20°F to 200°F | All-Season Reliability: Bond is designed to resist high heat and cold, performing consistently across a wide service temperature range similar to leading high-performance HVAC adhesives. |

| Distinctive Green Color | Visual Quality Control (QC): The green color allows for instant visual confirmation of 100% coverage on the substrate, eliminating costly misses and ensuring compliance. |

| Web / Lace Spray Pattern | Zero Soak-In: Controlled pattern minimizes waste and ensures the adhesive remains on the material surface for a better bond, especially on porous fiberglass. |

| Aggressive Acetone/Heptane Solvents | WARNING: This aggressive base will dissolve low-density Polystyrene/Styrofoam/EPS foam materials. Do not use on foam substrates. |

Part Number Reference:

| PART # | NET WEIGHT | APPLICATION FIT |

|---|---|---|

| MGA-1 | 12 oz – 6/cs | Portable / Service: Disposable aerosol for rooftops, smaller installations and repair work. |

2. Alternative Mean Green Configurations

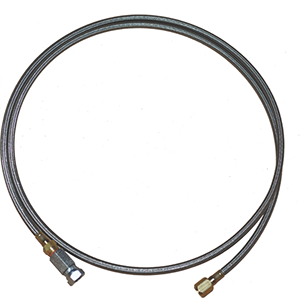

| Cylinders | Mean Green or Mean Green Long Tack |

| Bulk | 1, 5, 55 gallon |

| Accessories | Hoses, Guns, Brushes, Remover |

Contractors: Please contact your local Vapco distributor for pricing and availability.

Directions for Mean Green Aggressive Tack High Solids Contact Adhesive:

Pre-Application Checklist

- Warning: Do not use on Polystyrene, Styrofoam, or any EPS/XPS foam, as this aggressive solvent formula will dissolve the material.

- Ensure both surfaces are clean, dry, and free of oil, dust, or grease.

- Shake the can vigorously before use.

- Maintain the optimal application temperature for the adhesive between between 60°F and 90°F (15°C and 32°C).

Application

- Hold the can 4–8 inches from the surface. Spray in a sweeping, side-to-side motion for even coverage.

- For Permanent Contact Bonding: Apply the wide Green Web Spray evenly to both surfaces to be joined. Allow a 30–60 second flash time for the fast-evaporating solvents to dissipate, then mate the surfaces and apply firm pressure.

- For Temporary Bonds: Apply adhesive to one surface only and allow it to become fully tacky before applying the material.

- Prevent Clogging: Immediately after use, invert the can and spray a few short bursts to clear the valve. Wipe away any adhesive buildup around the nozzle opening while wet.

Stop settling for slow-tacking, generic adhesives. Choose Mean Green (MGA-1): End bond failure and slow application. Choose the quickest contact adhesive engineered for Aggressive Tack, Highest Solids, and Visual Quality Control.