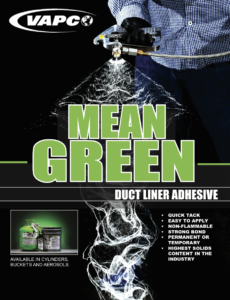

MEAN GREEN BULK

Versatile and Powerful Adhesive

MEAN GREEN is a cost-effective, high-performance adhesive designed for a wide range of applications. Its unique formulation provides instant tack, strong bonds, and resistance to heat, cold, and moisture.

Key Features and Benefits:

- Quick Tack and Strong Bonds: Forms a secure bond quickly and effectively.

- Versatile Applications: Suitable for a variety of materials and applications.

- Non-Flammable: Safe to use and handle.

- Permanent or Temporary Bonding: Offers flexibility for both permanent and temporary applications.

- Highest Solids Content: Provides superior adhesion and durability.

- Controlled Spray Pattern: Ensures precise application and minimal waste.

- Low Soak-In Rate: More adhesive remains on the surface for optimal bonding.

- MEAN GREEN BULK: Compatible with existing spraying systems for larger-scale applications.

Note for California, Utah, and Connecticut Customers: To comply with VOC regulations, please order MAGNA TACK (MTA-1).

MEAN GREEN is a reliable and versatile adhesive solution that can be used in a variety of applications, including duct lining, construction, and general bonding. Its exceptional performance, ease of use, and cost-effectiveness make it a valuable asset for professionals and DIY enthusiasts alike.

Mean Green Bulk

Mean Green Bulk can be used with an existing spraying system, or it can be brushed or rolled on. The same fast tack and strong bond as our cylindered and aerosol versions.

Part Number: Size

- MG-1 1 gal 4/cs

- MG-5 5 gallons

- MG-55 55 gallons

Directions:

Effective Application for Strong and Durable Bonds

- Prepare Surface: Ensure the surface is clean and free from debris, dust, dirt, grease, or other contaminants.

- Wear Protective Gear: Wear goggles, gloves, and protective clothing for safety.

- Apply Base Coat: Spray, brush, or roll a light coat of MEAN GREEN adhesive inside the sheet.

- Apply Edge Coat: Apply a thicker coat of adhesive around the edges to provide strong bonding strength.

- Contact Cement: Spray a light coat on both the insulation and metal to use the adhesive as a contact cement.

By following these steps, you can effectively apply MEAN GREEN adhesive for secure and durable bonding.

DANGERS & PRECAUTIONS

Read and understand the product’s label and Safety Data Sheet. Keep out of reach of children. Causes skin and eye irritation. Suspected of causing cancer. Do NOT handle or use this product until all safety precautions have been read and understood. Keep away from heat, sparks, open flames, and hot surfaces. Eliminate all ignition sources if safe to do so. Protect from sunlight. Wear protective gloves.

Contact Us

News and Updates

Subscribe on Youtube

Follow Us on Facebook

SDS

⚠️ MEAN GREEN ADHESIVE LIQUID SDS – DOWNLOAD

Identification & Supplier Details

| Product Name (GHS Identifier) |

Mean Green Long Tack Liquid |

| Product Number |

MGLT-1, MGLT-5, MGLT-55 |

| Brand |

Vapco |

| Recommended Use |

Solvent-based contact adhesive |

| Restrictions on Use |

After December 8, 2026, cannot be distributed in commerce to retailers for any use. Various specific industrial/commercial uses allowed after March 8, 2027 (see full SDS for details). |

| Supplier Name |

Vapco Products, Inc. |

| Supplier Address |

401 Marshall Road, Valley Park, Missouri 63088, United States |

| Supplier Telephone |

(636) 923-2121 |

| Supplier Fax |

(636) 923-3002 |

| Supplier Email |

[email protected] |

| Emergency Phone Number |

(800) 255-3924 |

Hazard Identification & Composition

| General Hazard Statement |

| Caution: Non-Flammable Adhesive Mixture: Contains a component that is flammable in its pure state according to GHS definitions, however when combined in the overall adhesive mixture the adhesive is not flammable in either its liquid or dry states. |

| GHS Classification |

Acute toxicity, inhalation, Cat. 4; Aspiration hazard, Cat. 1; Carcinogenicity, Cat. 2; Skin corrosion/irritation, Cat. 2; Specific target organ toxicity (single exposure), Cat. 3 |

| Signal Word |

Warning |

| GHS Pictograms |

|

| Hazard Statement(s) |

- H304: May be fatal if swallowed and enters airways

- H315: Causes skin irritation

- H332: Harmful if inhaled

- H335: May cause respiratory irritation

- H336: May cause drowsiness or dizziness

- H351: Suspected of causing cancer

|

| Precautionary Statement(s) (Selection) |

- P201: Obtain special instructions before use.

- P261: Avoid breathing dust/fume/gas/mist/vapors/spray.

- P280: Wear protective gloves/protective clothing/eye protection/face protection.

- P301+P310: IF SWALLOWED: Immediately call a POISON CENTER/doctor.

- P331: DO NOT induce vomiting.

- P405: Store locked up.

- P501: Dispose of contents/container to the specifications of local, regional, national, and international regulations.

|

Hazardous Components

| Chemical Name |

CAS No. |

Concentration (% weight) |

EC No. |

| Tetrachloroethylene |

127-18-4 |

55 – 65 % |

204-825-9 |

Physical & Chemical Properties

| Physical State |

Liquid |

| Color |

Green |

| Odor |

Chlorinated solvent odor |

| Melting Point/Freezing Point |

-8.4°F (-22.4°C) |

| Boiling Point |

250°F (121.1°C) |

| Flammability |

Non-flammable |

| Flash Point |

N/D |

| pH |

N/A |

| Solubility (in Water) |

Insoluble in water |

| Vapor Pressure |

14.7 mmHg at 20°C (Perchloroethylene) |

| Density/Relative Density |

1.43 g/L |

| Relative Vapor Density (Air=1) |

5.83 |

Stability & Reactivity

| Reactivity |

May be reactive to chemically active metals and bases. Certain mixtures of chlorinated solvents may be flammable or reactive. |

| Chemical Stability |

Stable under normal conditions of use. |

| Possibility of Hazardous Reactions |

None known. |

| Conditions to Avoid |

Open flame, electric arcs, or other hot surfaces (may cause thermal decomposition). Chlorine liberating material. Do not mix with acids, ammonia, or other cleaning compounds. |

| Incompatible Materials |

Some plastics, strong oxidizing agents, acids, caustics, alkalis, and chemically active metals (e.g., aluminum, magnesium, sodium, potassium, and lithium). May react with freshly galvanized surfaces to produce highly toxic dichloroacetylene. |

| Hazardous Decomposition Products |

Hydrogen chloride, phosgene, chlorine, hexachloroethane, hexachlorobenzene, and carbon oxide(s). |

Toxicological Information

| Acute Toxicity Data (Tetrachloroethylene) |

LD50 Dermal (Rabbit): >3,228 mg/kg

LD50 Oral (Rat): >2,629 mg/kg

LC50 Inhalation (Rat): 34,200 mg/m3 – 8 hr |

| Skin Corrosion/Irritation |

Irritating to skin. Causes localized defatting, drying, cracking, and dermatitis with prolonged or repeated contact. |

| Serious Eye Damage/Irritation |

Causes mild irritation, redness, burning, and tearing. |

| Respiratory Sensitization |

Harmful by inhalation. Vapors may cause irritation, dizziness, headaches, and CNS depression. High exposure may cause anesthetic effects, unconsciousness, and potentially fatal cardiac arrhythmias (cardiac sensitization). |

| Carcinogenicity (Tetrachloroethylene) |

IARC: 2A (Probably carcinogenic to humans)

NTP: Reasonably anticipated to be a human carcinogen

OSHA: Not listed as a carcinogen. Suspected of causing cancer. |

| STOT – Single Exposure |

May cause drowsiness or dizziness. |

| STOT – Repeated Exposure |

Repeated or prolonged exposure may be toxic to kidneys, liver, skin, central nervous system (CNS). |

| Aspiration Hazard |

Yes. May be fatal if swallowed and enters airways. |

First-Aid Measures

| General Advice |

Seek medical advice if feeling unwell (show label if possible). Never give anything by mouth to an unconscious person. |

| If Inhaled |

Remove person to fresh air. Keep comfortable for breathing. Get medical advice/attention. Excessive exposure may cause respiratory irritation, headaches, loss of consciousness, and cardiac sensitization. |

| In Case of Skin Contact |

Immediately drench affected area with water for at least 15 minutes. Remove contaminated clothing. Obtain medical attention if irritation persists. |

| In Case of Eye Contact |

Immediately rinse with water for at least 15 minutes. Remove contact lenses. Obtain medical attention if irritation persists. |

| If Swallowed |

Rinse mouth. DO NOT induce vomiting. Obtain medical attention. Aspiration hazard is a major concern. |

| Note to Physician |

No specific antidote. Treat symptomatically. Avoid adrenaline/epinephrine and similar sympathomimetic drugs as cardiac arrhythmia may result. Aspiration risk must be weighed. |

Fire-Fighting & Accidental Release Measures

| Suitable Extinguishing Media |

Dry chemical, foam, or carbon dioxide (CO2). |

| Specific Hazards (Fire) |

Container may explode in heat of fire. Vapors are heavier than air. Incompatible with many materials (see Stability). |

| Firefighting Actions |

Fight fire remotely due to explosion risk. Shut off all sources of ignition. Use water spray/fog for cooling exposed containers. Wear NIOSH-approved SCBA. |

| Hazardous Combustion Products |

Hydrogen chloride, phosgene, chlorine, and carbon oxides. |

| Personal Precautions (Spill) |

Do not breathe vapors. Keep away from heat, sparks, open flames, and other ignition sources. Use appropriate PPE. |

| Environmental Precautions (Spill) |

Prevent entry to sewers and public waters. Avoid release to the environment. |

| Methods for Containment/Cleanup |

Eliminate all ignition sources first. Ventilate the area. Contain spills with dikes or absorbents. Take up liquid spill into absorbent material and transfer to a suitable container for disposal. |

Handling, Storage & PPE

| Precautions for Safe Handling |

Do not handle until all safety precautions are read and understood. Avoid contact with skin and eyes. Do not breathe vapors. Follow grounding procedures. |

| Conditions for Safe Storage |

Store in a dry, cool, well-ventilated place. Keep only in the original container. Protect from sunlight, extreme temperatures, and incompatible materials. Store locked up. |

| Engineering Controls |

Ensure adequate ventilation, especially in confined areas. Use explosion-proof equipment. Emergency eye wash fountains and safety showers must be available. |

| Eye/Face Protection |

Chemical safety goggles. |

| Skin/Body Protection |

Wear protective gloves and clothing. Use chemical resistant materials/fabrics. Wear fire/flame resistant/retardant clothing. |

| Respiratory Protection |

Use a NIOSH-approved Self-Containing Breathing Apparatus whenever exposure may exceed established Occupational Exposure Limits. |

Exposure Control Parameters (Tetrachloroethylene)

| Limit Type |

Value |

Source |

| IDLH (Inhalation) |

150 ppm |

(NIOSH) |

| TWA (Inhalation) |

25 ppm |

(US/OSHA & ACGIH) |

| STEL (Inhalation) |

100 ppm |

(ACGIH) |

Transport & Regulatory Information

| Information |

No specific transport or regulatory data (e.g., DOT, IMDG, IATA) provided in the source SDS. Refer to local, regional, national, and international regulations for transport. |

Disposal & Ecological Information

| Product Disposal |

Dispose of contents/container in accordance with local, regional, national, and international regulations. Containers may be hazardous when empty. Do not pierce or burn. |

| Sewage Disposal |

Avoid release into the environment. Keep out of sewers and waterways. Material is hazardous to the aquatic environment. |

| Toxicity (Tetrachloroethylene LC50 – 96 hr) |

Fathead Minnow: 18.4 ppm

Bluegill: 12.9 ppm

Rainbow Trout: 5 ppm |

| Persistence and Degradability |

Biodegradation under aerobic conditions is low. Degradation expected fairly rapidly in the atmosphere. Persists in groundwater. |

| Bioaccumulative Potential |

Not expected to significantly bio-accumulate in aquatic organisms or absorb to sediment. |

| Mobility in Soil |

Product can leach through soil to reach groundwater. Potential for mobility in soil is medium. |

Disclaimer & Preparation Information

| Disclaimer/Statement |

The SDS source material did not contain a standard Section 16 (Disclaimer/Preparation Information). This section serves as a placeholder for completeness according to the custom structure request. |