Non-Flammable Solvent Contact Adhesive for HVAC Insulation: Mean Green Cylinders MG- SC, LC, 200

High Solids, Methylene Chloride Free, Solvent Formula for Instant Productivity

The adhesive industry is navigating a massive regulatory shift. As the EPA eliminates Methylene Chloride (MeCl), contractors and wholesalers are facing a tough question: “How do I keep my shop safe and my insurance premiums low without sacrificing production speed?”

Mean Green is your answer. Non-Flammable Solvent Contact Adhesive for HVAC Insulation.

We engineered this formula as a strategic “Bridge Solution” for the HVAC industry. It replaces outdated MeCl technology with a high-performance, non-flammable solvent system. With an impressive ≈30% Solids content and ≈18% VOCs, it delivers the aggressive tack and instant grab you rely on for commercial fabrication, without the liability risks of flammable adhesives.

Performance First: We didn’t water it down. This is a heavy-bodied, industrial-grade adhesive designed for the speed of HVAC fabrication. It offers a 1–4 minute tack time and cures fully in 5–6 minutes.

Versatile Bonding: The resulting bond is a permanently flexible film that resists aging and thermal cycling. It is the ideal choice for bonding fiberglass insulation, bubble wrap, and duct liner to sheet metal. It also performs exceptionally well on rubber, plastic, wood, and automotive upholstery.

PRO TIP: Watch Your Tip! For the perfect spray pattern and zero waste, we recommend using Tip 6501 with our adjustable spray gun (SPR-AG). The gun is packaged with both tips so use the right one for the best results.

| KEY FEATURE / SPECIFICATION |

TRADE BENEFIT / RESULT |

| Non-Flammable Status (Wet & Dry) |

Job-Site Safety & Insurance: Truly non-flammable. Eliminates fire risk and satisfies strict safety and insurance requirements for commercial fabrication shops. |

| High Solids Content: ≈ 30% |

Superior Yield & Bridging: Delivers a heavier resin load that sits on top of porous fiberglass and duct liner rather than soaking in, ensuring a permanent structural bond with less product usage. Typical industry competitive adhesives have 20% solids. |

| Quick Tack & Working Time (1-4 min) |

Instant Productivity: Fast-flashing solvent system allows for immediate handling and insulation mating, reducing shop downtime. Full cure in 5–6 minutes. |

| VOC Content: ≈ 18% |

Precision Formulation: Engineered solvent balance ensures consistent evaporation rates and reliable performance across varying shop temperatures. |

| Methylene Chloride-Free |

Safety Bridge Solution: Replaces restricted MeCl solvents with a non-flammable alternative, keeping your shop compliant with current EPA safety mandates. |

| Distinctive Green Color |

Visual Quality Control (QC): The green color allows for instant visual confirmation of 100% coverage on the substrate, eliminating costly misses and ensuring airtight seals. |

| Controlled Web Spray Pattern |

Zero Waste & Cleanliness: Ensures precise application with minimal overspray/misting, keeping the adhesive on the insulation and off the floor. |

| Requires Tip 6501 |

Viscosity Warning: For best results, you MUST use Tip 6501 to achieve a proper web pattern. Standard tips will not spray correctly. |

| WARNING: Contains Perchloroethylene (PCE) |

TSCA & Inventory Planning: This product is a strategic stop-gap.

• Dec 8, 2026: Distribution to retailers ends.

• Mar 8, 2027: Commercial/Industrial use ends. |

Part Number Reference:

Select the right cylinder size for your job, and don’t forget the hose, spray gun and universal adhesive remover to keep you spraying.

1. Select Your Cylinder

| PART # |

NET WEIGHT |

APPLICATION FIT |

| MG-SC |

12 lbs |

Portable / Service: Lightweight disposable tank for rooftops, smaller installations and repair work. |

| MG-LC |

40 lbs |

Shop Standard: The #1 choice for fabrication shops. Best balance of mobility and volume. |

| MG-200 |

200 lbs |

Production: High-volume stationary setup for automated lines or large duct runs. |

2. Accessories – for the absolute best performance, be sure to use Vapco equipment with your cylinders.

| Spray Gun |

SPR-AG

Professional Adjustable Spray Gun (Comes with Tip 6501 & 730116)

MG Requires tip 6501 for best results |

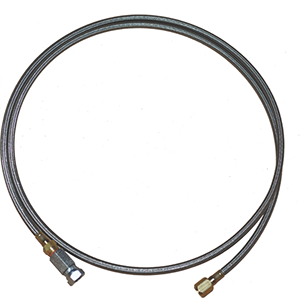

| Hoses |

THA- 6, 12, 18

Teflon Hose Assemblies (Available in 6ft, 12ft, and 18ft lengths) |

| Cleanup |

UAR-SC

Adhesive Remover Spray (Essential for cleaning gun tips and overspray) |

Contractors: Please contact your local Vapco distributor for pricing and availability.

Directions for Non-Flammable Solvent Contact Adhesive for HVAC Insulation (MG):

Pre-Application Checklist (Safety & Setup)

This section ensures job-site safety and optimal bond strength.

- Ventilation is Mandatory: This product contains chlorinated solvents (Perchloroethylene). Use outdoors or in a well-ventilated area with forced air movement. Consult the SDS for required PPE.

- Surface Preparation: Ensure both surfaces are clean, dry, and completely free of dirt, oil, or mold release agents.

- Temperature Check: Maintain the adhesive and substrate temperature between 60°F-90F for optimal spray pressure and tack development.

- Non-Flammable Safety: Although the mixture is non-flammable, keep the work area clear of ignition sources, heat, and sparks.

Application Procedure (Cylinder Use)

This procedure ensures maximum yield and speed.

- Hose, Gun & Tip: Attach the hose and spray gun to the cylinder. Make sure THA (teflon hose) and SPR-AG (Adjustable spray gun) are in good working order and free of dried glue, use tip 6501 for best spray pattern.

- Maintain Distance: Hold the spray gun nozzle 6–10 inches from the surface.

- Spray Technique: Apply a thin, even coat of Mean Green to both surfaces (contact bond style), ensuring 80-100% coverage. Use a side-to-side sweeping motion to avoid uneven pooling.

- Allow to Tack (Open Time): Wait 1–4 minutes. This is the critical working window (Open Time). The adhesive should feel tacky to the touch and should not transfer to your finger when lightly pressed.

- Bond: Once the adhesive is tacky, carefully align the coated surfaces and press them together firmly. The immediate strength of the adhesive will prevent shifting.

Post-Bonding and Cleanup

- Handling Strength: Do not disturb the bond for 5–6 minutes. This is the fast-acting bonding time (or Dry Time) where the adhesive achieves initial handling strength.

- Full Cure Time: Allow 24 hours for the bond to achieve maximum structural integrity and peak thermal resistance.

- Cleanup: If the adhesive cylinder is going to sit for more than 72 hours without being sprayed, close the cylinder, purge the hose and gun and connect to UAR-SC to clean the components and increase longevity of the hose, gun and tip.

Transparency & Regulatory Roadmap (Distributor Notice)

At Vapco, we believe in full transparency with our partners. This Non-Flammable Solvent Contact Adhesive for HVAC Insulation formula utilizes Perchloroethylene (Perc/PCE) to achieve its non-flammable safety rating. We view this as a vital transition tool—a reliable stop-gap that keeps your business running safely while the industry adapts to new non-solvent technologies.

Please note the following EPA compliance dates for inventory planning:

- Status Today: Fully Compliant for all Professional Uses.

- December 8, 2026: Deadline for distribution to retailers.

- March 8, 2027: Deadline for commercial and industrial use.

This gives you a clear runway to use this proven product while Vapco works alongside our chemical supply partners to finalize the next generation of permanent, non-flammable solvent technologies.

FAQs

Frequently Asked Questions: Mean Green (MG)

Application & Performance

Q: What spray tip should I use for Mean Green Cylinders? A: For the best spray pattern and minimal waste, we recommend using Tip 6501 with a standard adjustable spray gun. This tip is optimized for our high-solids web pattern, ensuring you get the right amount of glue on the liner without overspray.

Q: What is the tack time and open time? A: Mean Green is designed for speed. It has a fast tack time of 1–4 minutes (depending on humidity). Once tacky, you have an open working window of approximately 20 minutes to position the insulation before the bond sets.

Q: Can I use this on Styrofoam or Polystyrene insulation? A: NO. Mean Green (MG-LC) contains aggressive solvents that will dissolve low-density polystyrene foam (EPS/XPS). For foam board applications, please check our water-based or specific foam-compatible adhesives.

Q: Is this a “Contact Adhesive”? Do I spray one side or two? A: Yes, this is a true contact adhesive. For a permanent structural bond—especially on heavy duct liner—you must spray a uniform coat on BOTH surfaces (the metal and the insulation). Allow both to tack up before compressing them together.

Q: How much coverage can I expect from a 40lb cylinder? A: While usage varies by installer technique, the high-solids formula generally yields approximately 3,000+ sq. ft. of bonded coverage per 40lb cylinder when applied correctly.

Trouble Shooting

Q: Why is the spray pattern inconsistent or “spitting”?

A: This usually indicates one of a few things:

1. Wrong Tip: You are likely using a standard tip instead of the required Tip 6501.

2. Cold Cylinder: The adhesive is too cold. MG must be maintained between 60°F – 90°F. If the cylinder is cold, the pressure drops and the thick glue cannot spray properly. Warm the cylinder to room temperature before use, get it up off cold floors or away from exterior walls if possible.

3. Clogged Equipment: Clogged Equipment: if the hose or tip sit too long with product not being used the glue can start to setup and cause flow issues, use universal adhesive remover UAR-SC to purge the hose and tip of dry adhesive.

Safety & Compliance

Q: Is Mean Green truly Non-Flammable? A: Yes. Unlike many competitors that claim “non-flammable” but still have flammable propellants, Mean Green is certified Non-Flammable in both its wet (liquid) and dry states. This makes it safe for use in shops with strict insurance policies regarding fire hazards.

Q: Does this product contain Methylene Chloride? A: No. Mean Green is 100% Methylene Chloride Free. We have reformulated to remove this restricted chemical while maintaining the non-flammable profile contractors need.

Q: Can I sell or use this product in California? A: No. Due to strict VOC regulations in California, Utah, and Connecticut, Mean Green (MG-LC) cannot be sold in these states. For a compliant alternative in these regions, please order Vapco MAGNA TACK (MTA-1).

Q: Does this product contain Perchloroethylene (Perc)? A: Yes. To achieve a non-flammable rating without Methylene Chloride, this formula uses Perchloroethylene. Please review the Safety Data Sheet (SDS) for proper handling and PPE requirements.

Logistics & Storage

Q: What is the shelf life of a cylinder? A: Mean Green cylinders have a manufacturer warranty of 1 year from the date of manufacture when stored correctly. Always store cylinders off the concrete floor in a cool, dry area. Do not expose to temperatures above 120°F (49°C). We have found cylinders working well past the 1 year warranty date when stored correctly.

Q: How long will this product be available? (EPA Regulations) A: Mean Green (MG-LC) is fully compliant for sale and use right now. Under the EPA’s TSCA guidelines, this product is approved for distribution to retailers until December 8, 2026, and for commercial use until March 8, 2027. Vapco is actively developing the next generation of adhesives to ensure a seamless transition before these dates.

Q: What sizes are available? A: We offer three sizes to fit your shop’s needs:

-

MG-SC: 12 lb (Portable / Service Tech size)

-

MG-LC: 40 lb (Standard Shop size)

-

MG-200: 200 lb (High Volume Production size)

SDS

⚠️ MGLT Safety Data Sheet (SDS)

Identification & Supplier Details

Product Identification (Section 1)

| Product Name |

Mean Green Adhesive Cylinder |

| Product Numbers / Brand |

MG-LC; MG-SC; MG-200 / Vapco |

| Recommended Use |

Contact adhesive |

| Restrictions on Use (PCE) |

After December 8, 2026: Cannot be distributed to retailers for any use.

After March 8, 2027: Use/processing with ≥ 0.1% PCE restricted to specific industrial/commercial uses (e.g., as solvent, intermediate, laboratory chemical, in adhesives/sealants, etc.) and export/disposal. |

Supplier Details

| Name / Address |

Vapco Products, Inc. / 401 Marshall Road, Valley Park, Missouri 63088, United States |

| Contact Information |

Telephone: (636) 923-2121 / Fax: (636) 923-3002 / Email: [email protected] |

| Emergency Phone Number |

(800) 255-3924 |

Hazard Identification & Composition

GHS Classification (Section 2)

| Key Hazards (OSHA 29 CFR 1910.1200) |

Acute toxicity, inhalation, Cat. 4

Aspiration hazard, Cat. 1

Carcinogenicity, Cat. 2 (Suspected)

Gases under pressure, liquefied gas |

| Signal Word |

Danger |

| Hazard Statement(s) |

H280: Contains gas under pressure; may explode if heated

H304: May be fatal if swallowed and enters airways

H332: Harmful if inhaled

H351: Suspected of causing cancer |

| Key Precautionary Statement(s) |

P201/P202: Obtain special instructions before use. Do not handle until all safety precautions are read and understood.

P301+P310: IF SWALLOWED: Immediately call a POISON CENTER/doctor.

P331: Do NOT induce vomiting.

P410+P403: Protect from sunlight. Store in a well-ventilated place. |

| General Hazard Statement |

Caution: Non-flammable Adhesive Mixture. (Contains a component that is flammable in its pure state, but mixture is non-flammable). |

Hazardous Components (Mixtures) (Section 3)

| Component Name |

CAS Number |

Concentration (wt%) |

| Perchloroethylene ($text{C}_2text{Cl}_4$) |

127-18-4 |

30 – 40 % |

| Trans-1,2-dichloroethylene |

156-60-5 |

10 – 20 % |

| Petroleum gases, liquified (Propellant) |

68476-86-8 |

4 – 6 % |

| Carbon Dioxide ($text{CO}_2$) |

124-38-9 |

3 – 4 % |

Physical & Chemical Properties

| Physical State / Appearance |

Liquid / Aerosol spray |

| Color / Odor |

Green / Solvent odor |

| Boiling Point (Propellant) |

-44°F (-42°C) estimated |

| Flammability / Flash Point |

Not considered a flammable or extremely flammable aerosol / N/D |

| pH / Solubility |

N/A / Insoluble in water |

| Density / Relative Vapor Density |

1.08 – 1.18 / 3.0 (Air=1) (Vapors are heavier than air) |

| Volatile Organic Content (VOC) |

18.5% |

Stability & Reactivity

| Reactivity / Chemical Stability |

Contains gas under pressure; may explode if heated. May be reactive to chemically active metals and bases. |

| Incompatible Materials |

Strong oxidizing agents, acids, caustics, alkalis, and chemically active metals (e.g., aluminum, magnesium, sodium, potassium, and lithium). Reacts with some plastics. |

| Conditions to Avoid |

Heat, hot surfaces, sparks, open flames, chlorine liberating material. Do not pierce or burn container, even after use. |

| Hazardous Decomposition Products |

Carbon oxide(s) ($text{CO}, text{CO}_2$). Various hydrocarbons. |

Toxicological Information

Acute Toxicity & Key Effects (Section 11)

| Inhalation Hazards (H332) |

Harmful if inhaled. High concentrations cause CNS depression, dizziness, drowsiness, headache, narcosis, asphyxiation, and potentially cardiac sensitization (especially with high stress/epinephrine). |

| Aspiration Hazard (H304) |

May be fatal if swallowed and enters airways. Do NOT induce vomiting. |

| Skin/Eye Irritation |

Causes serious eye irritation. Irritating to skin, causes defatting, dryness, and dermatitis. |

| Carcinogenicity (H351) |

Contains Perchloroethylene (PCE). Suspected of causing cancer (IARC Group 2A, NTP “reasonably anticipated”). |

| Chronic/Repeated Exposure (STOT) |

May produce adverse effects on the lungs, liver, kidneys, and skin. Associated with changes in neurological and immune parameters in studies. |

Toxicological Data (Perchloroethylene, CAS: 127-18-4)

| $text{LD}_{50}$ Oral (Rat) |

2,629 mg/kg |

| $text{LD}_{50}$ Dermal (Rabbit) |

3,228 mg/kg |

| $text{LC}_{50}$ Inhalation (Rat, 8 hr) |

34,200 $text{mg/m}^3$ |

First-Aid Measures

| General Advice |

If exposed or concerned, get medical advice/attention. Never give anything by mouth to an unconscious person. |

| If Swallowed (Critical) |

Rinse mouth. Immediately call a POISON CENTER/doctor. Do NOT induce vomiting. |

| If Inhaled |

Remove person to fresh air and keep comfortable for breathing. Get medical advice/attention. |

| In Case of Eye Contact |

Immediately rinse with water for at least 15 minutes. Remove contact lenses if present and easy to do. Continue rinsing. |

| Special Treatment Note |

Careful consideration should be applied preceding administration of epinephrine or similar heart-stimulating substances due to potential for cardiac sensitization from chlorinated solvent. |

Fire-Fighting & Accidental Release Measures

Fire-Fighting Measures (Section 5)

| Suitable Extinguishing Media |

Dry chemical, foam, or carbon dioxide ($text{CO}_2$). |

| Specific Hazards |

Container may explode if heated. Rupturing closed containers may spread fire. Fight fire remotely. Vapors are heavier than air. |

| Protection During Firefighting |

Wear NIOSH-approved Self-Contained Breathing Apparatus (SCBA). |

Accidental Release Measures (Section 6)

| Personal Precautions |

Do not get in eyes, on skin, or on clothing. Do not breathe vapors. Keep away from heat/ignition sources. Use appropriate PPE. |

| Containment/Clean-up Methods |

Stop leak if safe. Ventilate the area. Contain spills with dikes or absorbents. Take up liquid spill into absorbent material. |

| Environmental Precautions |

Prevent entry to sewers and public waters. Avoid release to the environment. |

Handling, Storage & PPE

Handling Precautions (Section 7)

| Safe Handling |

Do not handle until all safety precautions have been read. Avoid contact with skin, eyes and clothing. Wash hands thoroughly after handling. |

| Additional Hazards |

Do not pressurize, cut, or weld containers. Ruptured cylinders may rocket. Vapors may collect in low lying areas. |

Storage Conditions (Section 7)

| General Conditions |

Store locked up/in a secure area. Keep only in the original container in a cool, well-ventilated place away from ignition sources. Do not expose to temperatures exceeding 50°C/122°F. |

| Incompatible Materials |

Keep/Store away from strong oxidizing agents, acids, and chemically active metals. |

Exposure Limits (Perchloroethylene, CAS: 127-18-4)

| Type |

Value (ppm) |

Regulator |

| TWA (Time-Weighted Avg.) |

20 – 50 ppm |

EU/AU |

| STEL (Short-Term Exp. Limit) |

40 – 150 ppm |

EU/AU |

Personal Protective Equipment (PPE) (Section 8)

| Eye/Face Protection |

Chemical safety goggles. Emergency eye wash/safety showers required. |

| Skin/Body Protection |

Wear protective gloves and suitable chemical resistant/fire retardant clothing. |

| Respiratory Protection |

Use a NIOSH-approved Self-Contained Breathing Apparatus (SCBA) when exposure may exceed OELs. |

Transport & Regulatory Information

Transport Information (Section 14)

| DOT/IMDG/IATA (Not Provided) |

The SDS content for Section 14 was incomplete. Transport details (UN Number, Class, Proper Shipping Name) will depend on the final product classification (Aerosol, Limited Quantity, etc.) |

Regulatory Information (Section 15)

| Key Regulated Components (PCE) |

Perchloroethylene (CAS: 127-18-4) is subject to specific TSCA restrictions and is listed on various State Right-to-Know lists (MA, NJ, PA) and TSCA inventory. |

| Carcinogen Lists |

Perchloroethylene is classified as a Group 2A (Probably Carcinogenic to Humans) by IARC and “Reasonably Anticipated to be a Human Carcinogen” by NTP. |

Disposal & Ecological Information

Disposal Considerations (Section 13)

| Product Disposal |

Dispose of contents/container in accordance with local, regional, national, and international regulations. Do not pierce or burn container. |

| Waste Treatment |

Product should be fully characterized prior to disposal (40 CFR 261). |

Ecological Information (Section 12)

| Toxicity |

Toxicity data is available for Perchloroethylene and Trans-1,2-dichloroethylene to aquatic organisms. |

| Bioaccumulation Potential |

Perchloroethylene does not significantly bioconcentrate (BCF is 38.9). |

| Mobility in Soil |

Perchloroethylene can leach rapidly through soil to reach groundwater. Potential for mobility in soil is medium. |

Disclaimer & Preparation Information

Other Information (Section 16)

| Preparation Information |

Prepared by: Jessica Wilson

Date prepared: 3/18/2025 |

| Disclaimer Status |

N/A (Section 16 content was truncated in the provided data). |

Technical Data

⚠️ MG CYLINDER TDR – DOWNLOAD

Field Guide: Substrate Compatibility Matrix

Mean Green’s Non-Flammable High Solids Formula ensures compliance and reliable performance on commercial insulation while providing instant tack.

| SUBSTRATE A |

SUBSTRATE B |

BOND TYPE |

PERFORMANCE / WHY IT WORKS |

| Fiberglass Duct Liner / Duct Board |

Galvanized Steel / Aluminum |

Permanent |

High Solids (27-32%) creates a heavy web that bridges porous insulation without soaking in, ensuring structural hold. |

| Bubble-Wrap / Bubble-Foil |

Sheet Metal / Vinyl / Wood |

Permanent |

Non-flammable solvent blend provides rapid flash-off and excellent bite on aluminum lined insulation and plastic films without melting sensitive surfaces. |

| Rubber Sheeting / Urethane / Foam |

Metal / Wood / Paper |

Permanent |

Flexible cured film accommodates thermal expansion/contraction in HVAC systems. |

| Vinyl Fabrics / Leather / Felt |

Vehicle Interiors / Panels |

Permanent |

Heavy body formula prevents bleed-through on fabrics while delivering high shear strength. |

1. Physical & Chemical Properties

| PROPERTY |

SPECIFICATION |

| Flammability Status |

Non-Flammable (Wet & Dry States) |

| Solvent System |

Chlorinated Solvent Blend (Methylene Chloride Free) |

| Color / Appearance |

Green (Visual Coverage Indicator) |

| Solids Content (by weight) |

27% – 32% (High Solids) |

| VOC Content |

< 19% |

| Service Temperature Range |

-20°F to 200°F (-29°C to 93°C) |

2. Application & Performance Metrics

| METRIC |

PERFORMANCE DATA |

| Tack Time (Flash-Off) |

1 – 4 Minutes (Depending on Temp/Humidity) |

| Open Time (Working Window) |

Up to 10 Minutes |

| Cure Time (Full Structural Strength) |

5 – 6 Minutes (Handling Strength) / 24 Hours (Full Cure) |

| Cleanup Solvent |

Universal Adhesive Remover (UAR-SC) or compatible solvent |

3. Logistics & Compliance Checklist

| ITEM |

DETAILS / CLASSIFICATION |

| California Proposition 65 |

WARNING: Contains Perchloroethylene (Known to cause cancer) |

| TSCA Sunset Date (Retail) |

December 8, 2026 (Distribution to Retailers Ends) |

| TSCA Sunset Date (Commercial) |

March 8, 2027 (Commercial/Industrial Use Ends) |

| UN Number / Shipping Name |

UN1956, Compressed Gas, N.O.S. (Non-Flammable) |

|

Non-refillable, disposable cylinder

|

DOT 39 NRC 260/325 M1005. Federal law prohibits transportation if refilled -penalty up to $500,000 and 5 years imprisonment (49 U.S.C. 5124). |

4. Estimated Structural Performance Data*

| METRIC (ASTM Type) |

LAB ESTIMATED VALUE |

| Peel Strength (180° Peel) (Aluminum to Fiberglass) |

18 – 24 PIW (Pounds per Inch Width) |

| Shear Strength (Static Load) (Aluminum to Aluminum) |

> 125 PSI (Pounds per Square Inch) |

| Adhesion Failure Mode (Typical) |

Substrate Failure (Adhesive bond exceeds strength of low-density materials) |

*Vapco has not run certified laboratory tests (e.g., ASTM) to verify these specific metrics. Performance will vary based on application technique, substrate material composition, temperature, humidity, and curing conditions.