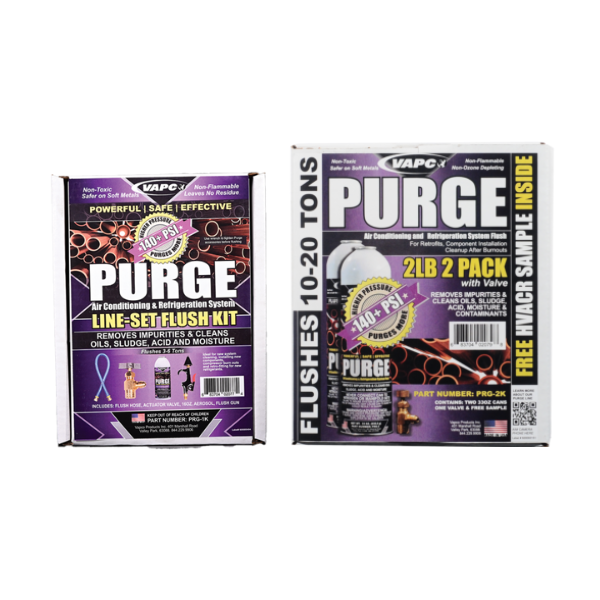

Purge High-Pressure HVAC Flush Kits : PRG- 1K, 1K-X3, 2K

Why flush when you can PURGE?

Other flush kits often rely on low-pressure solvents (~55 PSI) and off-the-shelf components that aren’t tuned for high-performance chemistry. Purge High-Pressure Kits are different. We combine our proprietary 140+ PSI solvent with professional-grade hardware engineered specifically for this formula.

The Purge system doesn’t just rinse the bottom of the pipe; it fills the line volume and obliterates obstruction. The high-pressure delivery ensures the solvent maintains velocity in cold weather and vertical commercial runs, while the active formula chemically emulsifies the sludge, carbon, and acids that cause compressor burnout.

| KEY FEATURE / SPECIFICATION | TRADE BENEFIT / RESULT |

|---|---|

| 1-Pound Starter Kit (PRG-1K) | Complete Turnkey System: Contains everything needed to start flushing immediately: 1 lb Aerosol, Reusable Flush Gun, 24″ Reinforced Hose, and Injection Valve. Ideal for residential service. |

| 2-Pound Commercial Kit (PRG-2K) | High-Volume Master Pack: Includes Two 2 lb canisters (4 lbs total) plus a heavy-duty actuator. Delivers enough solvent to clean up to 20 Tons, perfect for large commercial systems or fleet vehicles. |

| Engineered Hardware Compatibility | Minimal Seal Swelling: Injection valves and flush guns are engineered down to the o-rings to be fully compatible with the high-concentration solvent. Prevents the leaks and seal failures common with generic plastic kits. |

| 140+ PSI Delivery Pressure | Mechanical Scrubbing Force: Delivers nearly 3x the pressure of generic brands to blast through long vertical runs. The included reinforced hose handles this high pressure safely without bursting or kinking. |

| Non-Flammable & A2L Ready | Future-Proof Safety: Fully compatible with modern A2L (R-32, R-454B) conversions and R-410A retrofits. Non-toxic, non-flammable formula ensures job-site safety in occupied spaces. |

| Zero-Residue Evaporation | System Protection: Low-boiling point formula evaporates completely under standard vacuum, leaving no oily film or residue to contaminate the new refrigerant charge. |

| Universal Valve Technology | Standard Fit: All included injection valves feature standard 1/4″ flare connections, making the hardware reusable and compatible with standard manifold hoses if needed. |

| Application Requirement | Best Practice: For optimal results, always purge with clean, dry nitrogen after injection to push remaining solvent out, then evacuate the system prior to recharging. |

Part Number Reference:

Select the complete kit to get started, or stock up on refill canisters for your existing tools.

1. Select Your Kit or Refill

| PART # | SIZE / PACK | APPLICATION FIT |

|---|---|---|

| PRG-1K | 1 lb Kit (Sold Individually) |

Service Ready Starter: Includes (1) 1 lb Can, Gun, Hose, & Valve. The turnkey solution for residential repair. |

| PRG-1K-X3 | 1 lb Kit (Case of 3) |

Fleet Pack: Contains 3 complete Starter Kits. Perfect for outfitting multiple service trucks at once. |

| PRG-2K | 2 lb Kit (Sold Individually) |

Commercial Master Pack: Includes (2) 2 lb Cans + Actuator. High-volume solution for 20-ton systems. |

| RESTOCK AEROSOLS (Line-Set Flush Only) | ||

| PRG-1 | 1 lb Aerosol (Case of 6) |

Standard Refill: Replacement solvent for PRG-1K tools. Cleans 3–6 Tons. |

| PRG-2 | 2 lb Aerosol (Case of 4) |

High-Yield Refill: Replacement solvent for commercial jobs. Cleans 5–10 Tons. |

2. More Configurations & Accessories

| Cylinders | Large Cylinders (5 lb & 10 lb) Need to flush a VRF or Chiller? Switch to our bulk cylinders for massive volume and high pressure. |

| Tools | Purge Accessories Find replacement injection valves, hoses, and flush guns. |

| Aerosols | Purge Aerosol Page View the full technical details for the Purge 1 lb and 2 lb canisters. |

Contractors: Please contact your local Vapco distributor for pricing and availability.

Directions for Purge High-Pressure HVAC Flush Kits:

Safety & Hazard Warnings

- DANGER: Nitrogen Back-Pressure. Never connect the Purge canister directly to a Nitrogen line via a manifold. If Nitrogen back-pressure enters the aerosol can, it may burst.

- Ventilation: Use only in well-ventilated areas. If flushing indoors, open windows or use fans to exhaust fumes.

- PPE: Wear safety glasses and chemical-resistant gloves. Purge is a high-strength solvent that degreases skin instantly.

Phase 1: System Preparation

Before cracking the seal, ensure the system is isolated to prevent damage to sensitive components.

- Isolate & Protect:

- Compressors: Never inject solvent directly into a compressor.

- Metering Devices: Bypass or remove TXVs, pistons, and filter driers. Solvent can lodge debris in these small orifices.

- Large Components: If the system has a receiver or accumulator, inspect it visually. If heavily contaminated, bypass and clean separately or replace.

- Establish Flow Path:

- Disconnect the line set from the indoor and outdoor units.

- Whenever possible, plan to flush from the inside – out to the exterior. This moves fumes and contaminants outside.

- Place a bucket or waste container at the exit point to capture the solvent and sludge.

- High-Pressure Connections (Critical Step):

- Because Purge operates at 140+ PSI (significantly higher than standard flushes), hand-tightening may not be sufficient.

- Gently wrench-tighten the connection between the injection valve and the hose, and the hose to the flush gun.

- Caution: Do not over-tighten to the point of stripping threads, but ensure a firm, pressure-proof seal.

Phase 2: The Flushing Process

Leverage the high pressure and chemical solvency to scrub the line.

- The “Pro Tip” Restriction:

- Crimp the Exit: Use pliers to slightly crimp or restrict the end of the copper discharge line.

- Why? This creates back-pressure, forcing the liquid solvent to fill the volume of the pipe completely (increasing contact time) rather than just running along the bottom of the tube.

- Inject Purge:

- Connect the canister to your injection tool. Hold the canister upright.

- Inject solvent in short, controlled bursts based on tubing diameter:

- Up to 1/2″ Tubing: 10–20 second burst per 50 ft.

- Up to 7/8″ Tubing: 30–40 second burst per 50 ft.

- The Nitrogen Chase (Mandatory):

- Do not rely on the can pressure alone.

- Immediately after the solvent injection, disconnect the Purge canister and connect compressed Nitrogen (set to ~50 PSI).

- Blast Nitrogen through the line. This acts as a squeegee, driving the “plug” of solvent and suspended debris out of the line set.

Phase 3: Verification & Completion

Ensure the line is chemically clean and dry.

- Inspect the Discharge:

- Look at the waste container. The fluid will likely look dark/black initially (carbon and oil).

- Repeat: If the solvent exiting the line is not clear, repeat Steps 5 and 6 until the discharge runs clear and colorless.

- Evacuation:

- Once the line is clear, pull a deep vacuum on the line set.

- Purge is formulated with a low boiling point to flash off rapidly under vacuum, ensuring no chemical residue remains to contaminate the new refrigerant charge.

- Disposal:

- The waste container now holds hazardous contaminants (old oil, acid, sludge). Dispose of the waste solvent in accordance with local, state, and federal regulations (typically in a waste oil container).