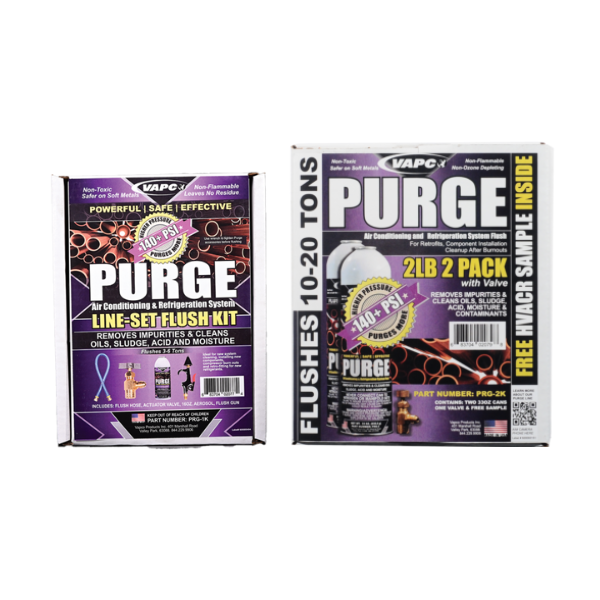

PURGE LINE SET FLUSH – KITS

Complete Solution for Line-Set Cleaning

Experience unmatched cleaning power with PURGE Line Set Flush – the professional’s choice for system decontamination. Each kit includes premium-quality components: high-pressure aerosol canisters, precision actuator valve, reinforced hose, and ergonomic flush gun. Our unique 140+ PSI delivery system ensures complete penetration and removal of stubborn contaminants. Whether you’re retrofitting older systems, recovering from burnouts, or ensuring clean installations, PURGE delivers consistent, reliable results that protect your reputation and your customer’s investment.

Key Features and Benefits:

- All-in-One Kit: Contains essential components for a complete cleaning process.

- 1-Pound Starter Kit: Includes 1 lb aerosol, actuator valve, reinforced hose, and flush gun

- Master Case Option: 3 complete kits for fleet vehicles and busy shops

- 2-Pound Commercial Kit: Two 2 lb canisters plus actuator for larger systems

- High-pressure delivery: 140+ PSI ensures thorough penetration

- Industry trusted: Preferred by professional HVAC contractors nationwide

- Non-flammable formula: Safe for use in occupied spaces

- Low-boiling formula: Completely evacuates under vacuum – no residue

- Universal compatibility: Safe for copper, aluminum, steel, and elastomers – won’t damage system components

- Rapid contamination removal: Dissolves oils, acids, moisture, and debris

- Certifications: DOT approved containers, EPA compliant formula

Part Number; Size

- PRG-1K 1 pound kit – every thing you need to get started – 1ea

- PRG-1K-X3 1 pound kit – 3/cs

- PRG-1 1 pound aerosol – 6/cs

- PRG-2K 2 pound kit – 2 x 2 pound aerosol + 1 actuator – 1ea

- PRG-2 2 pound aerosol – 4/cs

- AEROSOLS

- CYLINDERS

- ACCESSORIES

Directions:

Important pressure notice: Purge operates at higher pressures (140+ psi). For safety and leak prevention, gently wrench-tighten the connections:

- Between the actuator (injection valve) and hose

- Between the hose and the Purge-flush Gun

- Do not over-tighten.

- Establish the exit point: Choose one end of the line set as the discharge point. When possible, work from inside to outside.

- Create a slight restriction: Crimp or partially restrict the exit to increase mass flow and contact time of Purge through the tubing.

- Containment: Place a small container at the exit to capture solvent and contaminants.

- Deliver Purge: (typical starting guidance; actual amount varies by oil load, line configuration, and contamination)

- Up to 1/2 in. tubing: 10–20 second burst per line for every 50 ft

- Up to 7/8 in. tubing: 30–40 second burst per line for every 50 ft

- Nitrogen Purge: Immediately chase the Purge with nitrogen to drive solvent through the line set and maximize cleaning power. This helps ensure the solvent reaches the end of the run and removes loosened contaminants without waste.

- Inspect discharge: Check the catch container; it should show oils and other contaminants. Empty or replace the container and repeat step 3 (and step 4) until the discharge runs clear.

- Evacuate

Pull a vacuum on the line set to remove any residual solvent and moisture. Purge’s low boiling point promotes rapid boil-off under vacuum.

Completion

Once discharge is clear and evacuation is complete, the line set is clean and ready for service. Reassemble and return the system to operation.

Safety Guidelines & Additional Information:

System Preparation

- Isolate sections: Disconnect components for targeted cleaning

- Remove restrictions: Bypass compressor, TXVs, and remove filter driers

- Establish flow path: Create clear inlet and outlet points

- Prepare recovery: Set up containers for waste collection

Waste Disposal

- Contaminated flush will contain oils and system contaminants

- Transfer waste solvent to approved waste oil container for proper disposal

- Ensure containers are properly sealed if transport is required

Safety Precautions

- Ensure adequate ventilation, especially in equipment rooms

- Wear appropriate PPE: Safety glasses and chemical-resistant gloves

- Non-toxic, non-flammable formula for safer handling