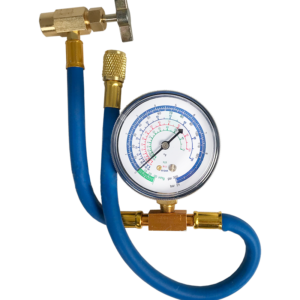

REFRIGERANT PIERCING SADDLE VALVE

When faced with a fully sealed refrigerant line, the PSV-1 provides a fast, secure, and non-permanent access point. Its precision-engineered clamping mechanism and sharp piercing needle ensure a clean, leak-free seal every time. The valve’s durable construction is designed to withstand the rigors of field use, providing HVAC professionals with a trusted method for servicing modern appliances and refrigeration units quickly and efficiently.

Key Features & Benefits

- Multi-Size Compatibility: Works with the most common line set sizes: 1/4″, 5/16″, and 3/8″ O.D. tubing.

- Creates a Temporary Service Port: Ideal for sealed systems, allowing for easy pressure testing, charging, and evacuation.

- Standard 1/4″ Male Flare Access Port: Connects directly to standard refrigerant hoses and manifold gauges.

- Simple Allen Wrench Installation: The two-bolt design clamps securely onto tubing for a stable, leak-proof connection.

- Durable, Leak-Proof Design: Robust construction ensures reliable performance and prevents refrigerant loss during service.

- R-290 & R-600a Systems: Perfect for accessing the sealed systems commonly found in appliances using hydrocarbon refrigerants.

Part Number

- PSV-1 1ea

Directions:

IMPORTANT: This valve is for temporary service access only. Permanent line repair is required after use. Read and understand all warnings and directions before use. Wear appropriate safety gear.

- Prepare: Ensure the piercing needle is fully retracted by turning the T-handle completely counter-clockwise.

- Install Valve: Position the two halves of the saddle valve around the refrigerant line. Securely tighten the clamp screws with an Allen wrench until the valve is firmly in place. Do not overtighten.

- Connect Hose: Attach your charging/service hose to the valve’s 1/4″ male flare service port.

- Pierce Line: Slowly turn the T-handle clockwise until the needle fully pierces the tubing. You will feel a slight change in resistance once the line is punctured.

- Service System: Turn the handle counter-clockwise to open the valve and allow refrigerant or vacuum flow. Proceed with charging, evacuation, or diagnostic procedures. Use a digital scale for accurate charging by weight.

- Removal and Repair: Once service is complete, the valve must be removed. The puncture in the line must be permanently repaired according to industry best practices and regulations (e.g., brazing or approved mechanical fitting).

NOTE: Failure to re-tighten piercing pin down to the shut-off position before removing the charging hose will result in the loss of all refrigerant!