Delayed Foaming Condenser Coil Cleaner | Liquid FM- 1, 5, 55 / FMB-1

The Coil Cleaner Your Coil Cleaner Wishes It Could Be.

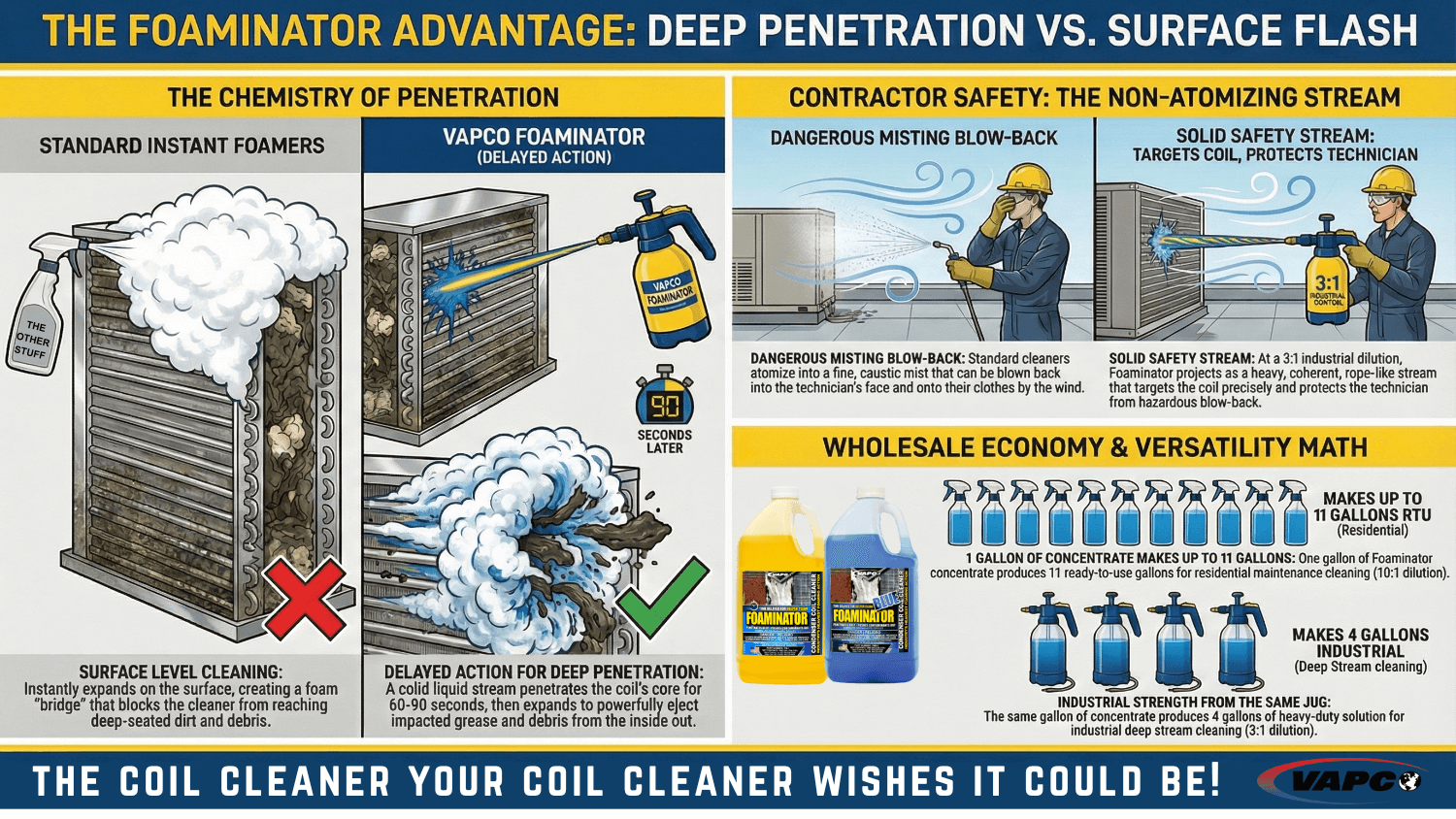

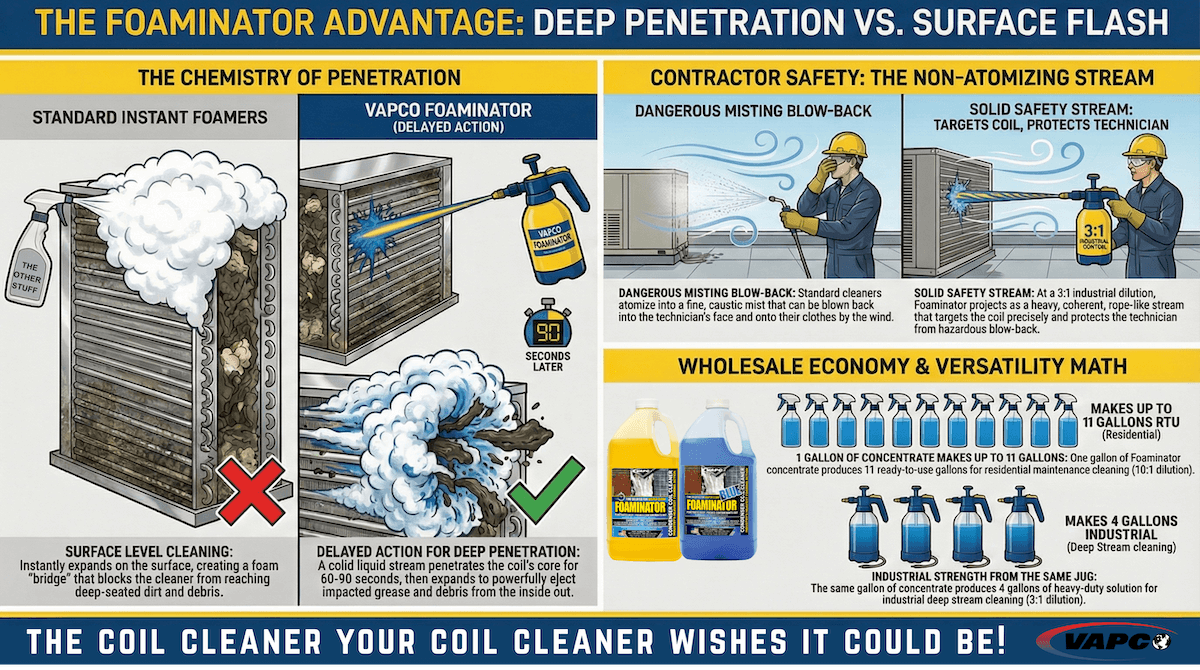

Standard “foaming” cleaners are like speedboats—they skim the surface. They react instantly upon contact, creating a wall of foam that actually prevents the liquid from reaching the center of the coil. Worse, they atomize upon exiting the sprayer, creating a cloud of caustic mist that drifts onto the technician, surrounding equipment and other surfaces that can cause significant damage. Foaminator is different, it’s designed to be a delayed foaming, condenser coil cleaner.

By utilizing a proprietary surfactant blend, Foaminator is engineered with a chemical time-delay. The liquid remains in a dense, penetrating state for 60 to 90 seconds (longer if it’s cold), seeping into all the cracks and crevasses, saturating debris with liquid before it starts to react with the metals. Only after it has reached the source of the blockages and begins to emulsify the buildup, does it expand with massive force, pushing the dirt, grease, grime, and anything else in its way, outward.

Manufacturer’s Tech Note: Foaminator is one of the most concentrated products on the market. Because of the high surfactant load, the viscosity is too thick for standard hose-end sprayers to draw properly. If using a hose-end sprayer, you must pre-dilute the product to allow it to “venturi” out. For best time-delay results, use a pump-up sprayer to control your exact dilution ratio.

The Efficiency Math: Industrial Power, Residential Safety

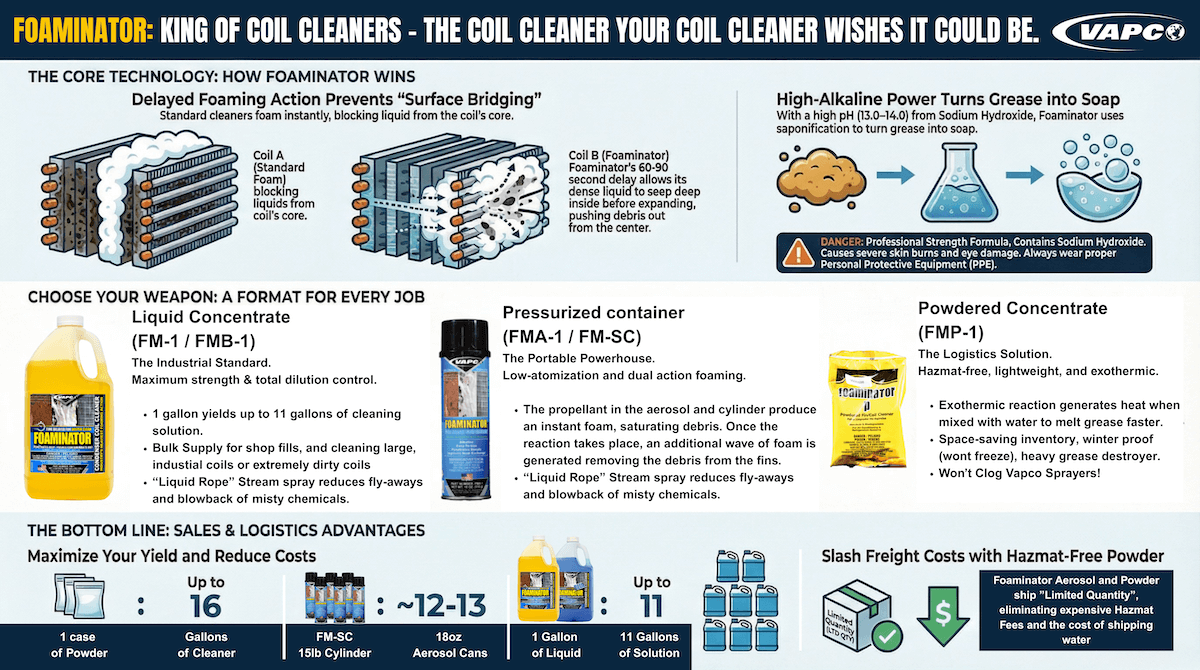

Because Foaminator relies on a premium Sodium Hydroxide base rather than water fillers, you have total control over the strength.

- 3:1 Ratio (Industrial): For impacted multi-row coils, industrial/ commercial setups, heavy soils, grease, and heavy oxidation.

- 10:1 Ratio (Residential): Highly effective for standard maintenance, lessening the concern of using caustic cleaners on sensitive residential units.

Professional Application: Ideal for industrial units, deep multi-row coils, and removing stubborn cooking grease, tar, and lint. Available in Yellow and Blue formulas.

| KEY FEATURE / SPECIFICATION |

TRADE BENEFIT / RESULT |

| Time-Delayed Action (60-90s) |

Deep Core Cleaning: Prevents “surface bridging.” The cleaner reaches the center of coils before expanding, pushing debris out from the center rather than just washing the surface. |

| High-Yield Concentration |

Cost Reduction: A single gallon can produce up to 11 gallons of cleaning solution. You are paying for active chemistry, not shipping water. |

| Proprietary Surfactant Blend |

Densest Foam Production: Creates a thick, heavy foam that clings to vertical surfaces longer, increasing dwell time and lifting heavy particulates like tar and lint. |

| Sodium Hydroxide Base (pH >13) |

Grease Saponification: Turns heavy cooking grease and oils into soap on contact, making them water-soluble and easy to rinse away. |

| Zero VOC / Low-Atomizing |

Technician Safety: Low mist formula reduces inhalation risks and meets strict environmental standards. |

| Material Compatibility |

Condenser Coils Only: Designed for copper tube/aluminum fin outdoor coils. Not for use on evaporator coils, coated micro-channel coils, or heat exchangers. |

| Non-Atomizing Stream (3:1 – 5:1) |

Technician Safety: Shoots like a liquid rope, not a cloud. Drastically reduces the risk of caustic mist drifting onto the technician’s face, arms, or uniform, especially in windy conditions. |

Vapco Field Guide: Performance Matrix

How Foaminator stacks up against real-world contaminants. (★★★ = Best in Class)

| CONTAMINANT |

RATING |

WHY IT WINS |

| Cooking Grease & Oil |

★★★ |

Saponifies heavy grease instantly. Rated Best-in-Class. |

| Corrosion & Oxidation |

★★★ |

Brightening Action: Strips white rust and dull oxidation from aluminum fins. |

| Grass, Bugs, & Cottonwood |

★★★ |

Delayed foam pushes organic matter out from the center instead of trying to push it through coils. |

| Tobacco / Nicotine Stains |

★★★ |

Rated Best-in-Class for removing sticky nicotine tar. |

| Dirt, Dust, Pollutants |

★★★ |

Heavy foaming action lifts microscopic particulates for easy rinsing. |

| Compatibility Warning |

RESTRICTED |

Condenser Coils ONLY. Do not use on Evaporators, Micro-Channel, or Electronic Air Filters. |

Part Number Reference:

Select the right volume for your workload. Available in Yellow and Blue formulations.

1. Select Your Size

| CONTAINER |

SIZE / PACK |

APPLICATION FIT |

| Gallon Bottle

FM-1 / FMB-1 |

1 Gallon

(Case of 4) |

Service Truck Standard: The most popular size. Easy to mix in standard pump sprayers. |

| 5 Gallon Pail |

5 Gallon Pail

(Sold Individually) |

Shop / Commercial Use: Ideal for refilling service truck containers or for large commercial roof-top jobs. |

| 55 Gallon Drum |

55 Gallon Drum

(Sold Individually) |

Industrial Facility: Bulk supply for large mechanical contractors and facility managers. |

Recommended Application Tools

Chemically resistant pump-up sprayers designed to handle high-alkaline concentrates like Foaminator.

| PART NUMBER |

CAPACITY |

SERIES FEATURES |

| STW-1 / STW-2 / STW-3 |

1, 2, & 3 Gallon |

Professional Standard: Heavy-duty polyethylene tank with chemically resistant seals and reinforced hose assemblies.

(Note: The 2-Gallon STW-2 is our most popular size for general service work.) |

| STW-2B / STW-3B |

2 & 3 Gallon |

Premium Brass Series: Upgraded with a solid brass spray wand and handle assembly for maximum durability and impact resistance. |

Maintenance Tip: To extend the life of your sprayer seals, always empty the chemical and rinse the tank/hose with fresh water at the end of the day.

3. Other Foaminator Configurations

| Aerosols |

Foaminator Aerosol The same deep cleaning power in a convenient, portable can. |

| Powder |

Foaminator Powder Save weight and space. The power of Foaminator in a lightweight powder concentrate. |

| Additional |

Foaminator Cylinder Large volume pressurized cylinders for massive commercial jobs. |

Contractors: Please contact your local Vapco distributor for pricing and availability.

Why “Instant Foam” Fails Your Coils – Use Delayed Foaming Condenser Coil Cleaner

| THE PAIN POINT (Traditional Cleaners) |

THE FOAMINATOR ADVANTAGE |

“Surface Bridging”

Foam activates instantly, blocking liquid from reaching the center of thick coils. |

“Delayed Penetration”

Liquid soaks for 60-90 seconds to reach the core, then expands to push debris out. |

“The Blow-Back”

Sprayer creates a fine mist that blows into the tech’s eyes and skin on windy days. |

“Non-Atomizing Stream”

Shoots a heavy, solid liquid stream (at 3:1) that lands on the coil, not the technician. |

“Shipping Water”

Pre-diluted formulas mean you pay for water and plastic waste. |

“11-Gallon Yield”

Super-concentrate makes up to 11 gallons of cleaner from one jug. |

FAQs

Frequently Asked Questions: Foaminator Coil Cleaner

Application & Performance

Q: Why doesn’t it foam immediately when I spray it?

A: This is by design. Foaminator features a “Delayed Foaming” mechanism. The liquid remains in a penetrating state for 60 to 90 seconds to soak deep into the center of the coil. Once it reaches the inner rows, the reaction triggers, expanding the foam to push debris out from the inside.

Q: Why is the liquid so thick? It shoots like a stream, not a mist.

A: We use a high-viscosity surfactant blend to create a Non-Atomizing Stream. This is a safety feature. By shooting a solid stream (at 3:1 dilution), the chemical lands exactly where you aim it—on the coil—rather than atomizing into a mist that blows back onto your skin or clothes in windy conditions.

Q: What is the difference between Yellow (FM-1) and Blue (FMB-1)?

A: Only the color. Both products use the exact same high-alkaline, delayed-foaming formula. We offer both colors because some contractors prefer Blue to see the coverage on the coil better, while others prefer the traditional Yellow to see the dirt contrast.

Q: Can I use this on indoor Evaporator Coils?

A: The short answer is NO. Evaporator coils are sensitive to pH and Foaminator requires heavy rinsing not easily done indoors. While we do not recommend Foaminator for evaporators, if you’re going to do it, pull the coil, heavily dilute with water before application and rinse immediately.

Q: I sprayed it and it didn’t foam. Is it broken?

A: Vapco manufactures this proprietary formula for several major industry brands under private label agreements. While the packaging may differ, Foaminator is the original, unadulterated formula. It is the exact product the manufacturer intended.

Q: Is this the same formula as other “Yellow” or “Blue” brands?

A: Vapco manufactures this proprietary formula for several major industry brands under private label agreements. While the packaging may differ, Foaminator is the original, unadulterated formula. It is the exact product the manufacturer intended.

Mixing & Equipment

Q: My hose-end sprayer isn’t drawing the chemical. Is it broken?

A: Likely not. Because Foaminator contains amazing surfactants with high viscosity, it is too thick for many standard hose-end sprayers to siphon effectively.

1. Best Method: Use a pump-up sprayer. This gives you total control over the dilution ratio and pressure.

2. Hose-End Workaround: If you must use a hose-end sprayer, pre-dilute the chemical (1 part water to 3 part Foaminator) in the sprayer cup so the venturi can draw it up.

Q: Will I get blowback burns on my arms or choke on the mist if it’s windy?

A: Foaminator solves that. At a 3:1 – 4:1 mix, it shoots like a heavy stream—like a laser. It hits the coil, not your face. It’s safer and cleaner than other cleaners that mist when sprayed.

Q: What is the best dilution ratio?

A: It depends on the job and contamination load:

- 3:1 -4:1 (Industrial): For virtually no misting, restaurant grease, impacted cottonwood, matted debris, and heavy oxidation.

- 5:1 – 7:1 (General): For reduced misting stay at 5:1. Most PM jobs will fall in this ratio for standard condensers and cleaning.

- 8:1 – 10:1 (Residential): For standard maintenance. This makes one gallon last up to 11 gallons of solution, offering unbeatable economy.

Safety & Compatibility

Q: Is this safe for Micro-Channel/Mini Splits coils?

A: NO. Foaminator is a high-pH alkaline cleaner designed for outdoor condensers only. It produces fumes that are not suitable for enclosed spaces, and the heavy foam requires high-volume rinsing that is difficult to manage indoors. We strongly recommend using a pH-neutral cleaner for micro-channel/mini-splits (MC-1 Mongoose or EC-1 Eco Clean).

Q: Do I need PPE? It says “Non-Atomizing.”

A: YES. While the non-atomizing stream reduces blow-back risk, this product contains Sodium Hydroxide and causes severe burns. Always wear goggles, chemical-resistant gloves, and long sleeves.

Q: Will it kill the grass around the unit?

A: Like any alkaline cleaner, concentrated runoff can damage vegetation. We recommend flooding the ground beneath the unit with water before and after cleaning to dilute the runoff, or covering nearby plants with a tarp. Never leave standing foam puddles after cleaning coils.

Logistics & Storage

Q: I have a massive roof job. Do you have larger sizes?

A: Yes. For commercial contractors and facility managers, we offer bulk sizes to reduce plastic waste and cost:

• FM-5: 5 Gallon Pail

• FM-55: 55 Gallon Drum

Q: What happens if the bottle freezes in my truck?

A: Foaminator is water-based and can freeze. However, it is stable. If frozen, simply thaw it at room temperature and shake well to remix the surfactants before use. Performance will not be affected.

Q: What is the shelf life?

A: Foaminator has a shelf life of 5+ years from the date of manufacture when stored properly. Warranty is 1 year.

Q: How do I dispose of the empty bottle?

A: Once triple-rinsed, the polyethylene (HDPE) bottles are fully recyclable. Check your local recycling guidelines.

Q: It costs more per gallon than the cheap stuff. Why?

A: You’re actually saving money. Foaminator is a Super Concentrate. While standard cleaners dilute less, one gallon of Foaminator makes up to 11 gallons of residential cleaner. Your cost per coil is actually lower.

SDS & Instructions

📄 DOWNLOAD FULL SDS (PDF)

⚠️ Professional Use OnlyContains Sodium Hydroxide. Causes severe skin burns and eye damage. Always wear chemical-resistant gloves, goggles, and protective clothing. DO NOT use on Micro-Channel or Mini-Split Coils.

Field Guide: Contaminant Removal Matrix

Foaminator utilizes a proprietary alkaline surfactant blend designed to penetrate deep multi-row coils. The following matrix details performance against common outdoor condenser obstructions.

| TARGET CONTAMINANT |

TYPICAL SOURCE |

ACTION |

PERFORMANCE / WHY IT WORKS |

| Cottonwood, Grass, Dirt & Bugs |

Landscaping / Seasonal Debris |

Deep Push-Out |

The “Inside-Out” Clean: Standard foams mat cottonwood onto the surface. Foaminator liquid penetrates past the debris, then expands 60-90 seconds later to push the matting out of the coil face. |

| Grease & Road Grime |

Kitchen Exhaust / Traffic Film |

Saponification |

High pH Sodium Hydroxide base chemically converts insoluble fats and heavy oils into water-soluble soap, while surfactants cut through sticky traffic film and road salts. |

| Oxidation & Corrosion |

Environmental Exposure |

Brightening |

Alkaline chemistry strips dull oxide layers and white rust from aluminum fins, restoring the bright metal finish and improving thermal heat transfer. |

| Pollutants & Soot |

Industrial Areas / Rooftops |

Suspension |

Dense foam structure lifts microscopic atmospheric pollutants and carbon soot away from the metal, suspending them for an easy rinse. |

System Material Compatibility

| MATERIAL / COMPONENT |

STATUS & PROTOCOL |

| Outdoor Condenser Coils |

✅ RECOMMENDED / RINSE REQUIRED |

| Micro-Channel / Mini-Split Coils (All Aluminum) |

❌ DO NOT USE

High pH will corrode brazed aluminum joints. |

| Indoor Evaporator Coils |

❌ DO NOT USE (Not Recommended)

Fumes and high-volume rinse requirements make this unsuitable for indoor use. With that said, we know you’re going to try it anyway…if you do, recover the refrigerant, pull the coil, take it outside where you have access to rinse easily and dilute Foaminator at 6 or 8 parts water to 1 part cleaner. Rinse heavily and thoroughly, removing all chemical and foam before re-installation. |

| Coated Fins |

⚠️ CAUTION

Alkaline cleaners may strip protective, manufacturers coatings. Test a small area first. |

Roof & Surroundings Safety Protocol:

Foaminator’s high-alkaline runoff can damage rubber roof membranes, asphalt, and vegetation. Always ensure all chemical and foam is completely flushed and diluted off the roof/pad during the rinse phase. Do not leave standing chemical or foam residue.

*For standard in-place evaporator cleaning, use Mongoose MCC-1 or High Tech Evap (HTEC-1) or Eco Clean (EC-1) in highly sensitive areas.

Directions for Delayed Foaming Condenser Coil Cleaner:

FM- 1, 5, 55 / FMB-1

1. Preparation & Dilution Ratios

Step 1: Protect the Surroundings. Alkaline runoff can kill grass and plants. Pre-soak the ground beneath the unit with water before cleaning and rinse heavily after.

Step 2: Mix Your Solution. Always add chemical to water, never water to chemical, to prevent splashing.

Step 3: Shut off power to the HVAC unit.

Step 4: Remove any heavy loose debris (leaves, grass) from the coil exterior with a brush or vacuum.

Tech Tip: Foaminator is high-viscosity. For best results, use a Pump-Up Sprayer. If using a hose-end sprayer, pre-dilute the cup 2:1 so the venturi can draw the liquid.

| APPLICATION |

RATIO |

RESULT / YIELD |

| Heavy Duty / Industrial |

3:1 to 4:1 |

Non-Atomizing Stream: Shoots deep into multi-row coils. 1 Gal makes 4 Gal of solution. |

| Medium Duty |

5:1 to 6:1 |

Standard Maintenance: Good balance of foam and economy. 1 Gal makes 7 Gal of solution. |

| Residential / Light |

8:1 to 10:1 |

Max Economy: Effective for surface dirt on sensitive residential units. 1 Gal makes 11 Gal of solution. |

2. Application & Cleaning

Leverage the time-delay for maximum penetration.

- Apply Solution:

- Spray the solution onto the coils, starting at the bottom and working your way up.

- Ensure the solution saturates the coil face.

- The Critical Wait (Dwell Time):

- Wait 5 to 8 minutes.

- Observation: You will notice the product does not foam immediately. This is the design. It is soaking into the center of the coil.

- After the delay, the reaction will trigger, pushing a dense white foam outward, carrying the dirt and debris with it.

3. Rinse & Completion

Flush away the saponified grease and debris.

- Rinse Thoroughly:

- Using a hose with a low-pressure spray or a pressure washer (carefully regulated to avoid bending fins), rinse the coil.

- Rinse from the top down to wash the debris away.

- Ensure all foam and chemical residue is removed from the coil and surrounding equipment.

- Restart:

- Restore power to the unit. The equipment is now clean and thermal efficiency is restored.

🧪 SDS SECTION: LIQUID FORMULA

(FM LIQUID-Series)

1. Identification & Supplier Details (Liquid)

| Product Name |

Foaminator (Liquid) |

| Product Numbers |

FM-1, FM-5, FM-55, FMB-1 |

| Recommended Use |

Condenser Coil Cleaner |

| Emergency Phone |

(800) 255-3924 |

2. Hazards Identification (Liquid)

| GHS Classification |

Skin Corrosion 1A; Eye Damage 1 |

| Signal Word |

DANGER |

| Hazard Statements |

H314: Causes severe skin burns and eye damage. |

| Precautionary Statements |

P260: Do not breathe mist/spray.

P280: Wear protective gloves/clothing/eye protection.

P303+P361+P353: IF ON SKIN: Take off contaminated clothing. Rinse skin with water/shower.

P305+P351+P338: IF IN EYES: Rinse cautiously with water. Remove contact lenses.

P310: Immediately call a POISON CENTER/doctor. |

3. Composition / Ingredients (Liquid)

| Component Name |

CAS Number |

Concentration |

| Sodium Hydroxide (NaOH) |

1310-73-2 |

15 – 30% |

| Alkyl / Decyl Octyl Glycosides |

110615-47-9 / 68515-73-1 |

1 – 3% |

4. First-Aid Measures

| Skin Contact |

CORROSIVE. Immediately take off contaminated clothing. Rinse skin with water/shower for at least 15 minutes. |

| Eye Contact |

SEVERE DAMAGE. Rinse cautiously with water for at least 15 minutes. Remove contact lenses. Get medical attention. |

| Inhalation |

Remove person to fresh air. Keep comfortable for breathing. |

| Ingestion |

Rinse mouth. Do NOT induce vomiting. Get immediate medical attention. |

5. Fire-Fighting Measures

| Suitable Extinguishing Media |

Water spray, fog, CO2, alcohol-resistant foam, dry chemical, or sand. |

| Specific Hazards |

May be corrosive to metals. Hazardous combustion products: Carbon oxides, Sodium oxides. |

| Special Protective Actions |

Wear NIOSH-approved SCBA with full face piece and full body protective clothing. Fight fire remotely if possible. |

6. Accidental Release Measures

| Personal Precautions |

Do not get in eyes, on skin, or clothing. Do not breathe vapors/spray. Wear PPE. |

| Environmental Precautions |

Prevent entry to sewers and public waters. Check pH before disposal (if >12.5, it is RCRA Hazardous). |

| Cleanup Methods |

Contain spill with dikes/absorbents. Neutralize residue carefully. Transfer to suitable containers. |

7. Handling & Storage

| Safe Handling |

Avoid contact with skin and eyes. Do not breathe mist/spray. Wash hands thoroughly after handling. |

| Safe Storage |

Store in a dry, cool, well-ventilated place. Store locked up. Keep in original container. Protect from sunlight. |

| Incompatible Materials |

Strong acids and chemically active metals (Aluminum). |

8. Exposure Controls / Personal Protection

| Exposure Limits |

Sodium Hydroxide: OSHA PEL / ACGIH TLV: 2 mg/m³ (Ceiling). |

| Engineering Controls |

Emergency eye wash fountains and safety showers must be available nearby. Ensure adequate ventilation. |

| PPE (Personal Protective Equipment) |

Eyes: Chemical safety goggles.

Skin: Chemical-resistant gloves and protective clothing.

Respiratory: NIOSH-approved SCBA if exposure exceeds limits. |

9. Physical & Chemical Properties

| Physical State |

Liquid |

| Color / Odor |

Clear / Various (Yellow or Blue) / Characteristic Odor |

| Solubility |

Completely Soluble in Water |

| pH |

>13 |

10. Stability & Reactivity

| Reactivity / Stability |

Stable under normal conditions. Reacts with chemically active metals and acids. |

| Conditions to Avoid |

Direct sunlight, extreme temps, incompatible materials. |

| Hazardous Decomposition |

Carbon oxides, Sodium oxides. |

11. Toxicological Information

| Acute Toxicity |

LD50 Oral (Rat) > 5,000 mg/kg (Surfactants) |

| Skin/Eye |

Causes severe skin burns and serious eye damage. Prolonged contact destroys tissue. |

| Carcinogenicity |

Not classified. |

12. Ecological Information

| Ecotoxicity (NaOH) |

LC50 Mosquito Fish: 125 mg/L (96h)

EC50 Water Flea: 40.4 mg/L (48h) |

| Persistence / Mobility |

Mobile in soil. No bioaccumulation expected. |

13. Disposal Considerations

| Disposal Method |

Dispose of in accordance with regulations. RCRA Hazardous Waste (D002) if pH > 12.5. |

| Container |

Containers may remain hazardous when empty. Do not puncture or incinerate. |

14. Transport Information

| Regulation |

UN Number |

Class |

Proper Shipping Name |

| DOT (US) |

UN1719 |

8 |

Caustic alkali liquids, n.o.s. (Sodium Hydroxide)

Packing Group: II |

15. Regulatory Information

| US Federal / State |

TSCA: Listed (Sodium Hydroxide, Alkyl polyglucoside).

Right To Know (MA, NJ, PA): Sodium Hydroxide. |

16. Other Information

| Preparation |

Prepared by: Jessica Wilson

Date: 2/14/2025

Version: 1.0 |

| Disclaimer |

The information provided is believed to be accurate but comes without warranty. User is responsible for full compliance with local regulations. |

Specs & Logistics

🛠️ FM-1, FM-1B TECHNICAL DATA REPORT – DOWNLOAD

1. Physical & Chemical Properties

| Base Chemistry |

Sodium Hydroxide (15-35%) with Proprietary Surfactants |

| pH Level (Concentrate) |

> 13.0 (Highly Alkaline) |

| Specific Gravity |

1.24 (High density fluid) |

| Viscosity |

High Viscosity (Requires pre-dilution for venturi sprayers) |

| VOC Content |

Zero VOC / Biodegradable |

| Solubility |

100% Soluble in Water |

| Appearance (FM Series) |

Yellow Liquid (Opaque) |

| Appearance (FMB Series) |

Blue Liquid (Opaque) |

| Odor |

Chemical / Odorless |

| Shelf Life |

5+ Years (Stored in closed container) |

| Freeze/Thaw Stability |

Stable. (Allow to thaw and shake well before use) |

2. UN & DOT Shipping Classification

| Proper Shipping Name: |

Corrosive Liquid, Basic, Inorganic, N.O.S. (Sodium Hydroxide) |

| UN Number: |

UN3266 |

| Hazard Class: |

8 (Corrosive) |

| Packing Group: |

II |

| Label Required: |

Corrosive (Class 8) |

3. Master Shipping & Dimensions Guide

| ITEM |

INDIVIDUAL UNIT |

QTY / CASE |

CASE SPECS |

PALLET CONFIGURATION |

CODE |

| Part # |

Wt (lbs) |

H (in) |

W (in) |

L (in) |

Units |

Wt (lbs) |

H (in) |

W (in) |

L (in) |

Cases/Pallet |

Total Units |

Wt (lbs) |

H (in) |

W (in) |

L (in) |

UPC |

FM-1

(1 Gal) |

[ ] |

[ ] |

[ ] |

[ ] |

4 |

[ ] |

[ ] |

[ ] |

[ ] |

48 |

192 |

[ ] |

[ ] |

40 |

48 |

683704031640 |

FMB-1

(1 Gal Blue) |

[ ] |

[ ] |

[ ] |

[ ] |

4 |

[ ] |

[ ] |

[ ] |

[ ] |

48 |

192 |

[ ] |

[ ] |

40 |

48 |

[ ] |

FM-5

(5 Gal Pail) |

[ ] |

[ ] |

[ ] |

[ ] |

1 |

N/A |

N/A |

N/A |

N/A |

N/A |

24 |

[ ] |

[ ] |

40 |

48 |

[ ] |

FM-55

(55 Gal Drum) |

[ ] |

[ ] |

[ ] |

[ ] |

1 |

N/A |

N/A |

N/A |

N/A |

N/A |

4 |

[ ] |

[ ] |

40 |

48 |

[ ] |

Harmonized Tariff Code (HTS): 3402.20.5100 (Cleaning Preparations)

NMFC Code: 48580 (Compounds, Cleaning, Liquid) – Class 55