Powdered Condenser Coil Cleaner | FMP-1

The Coil Cleaner Your Coil Cleaner Wishes It Could Be.

Stop Paying to Ship Water. The Undisputed King of Coil Cleaners… Dehydrated & Self-Heating.

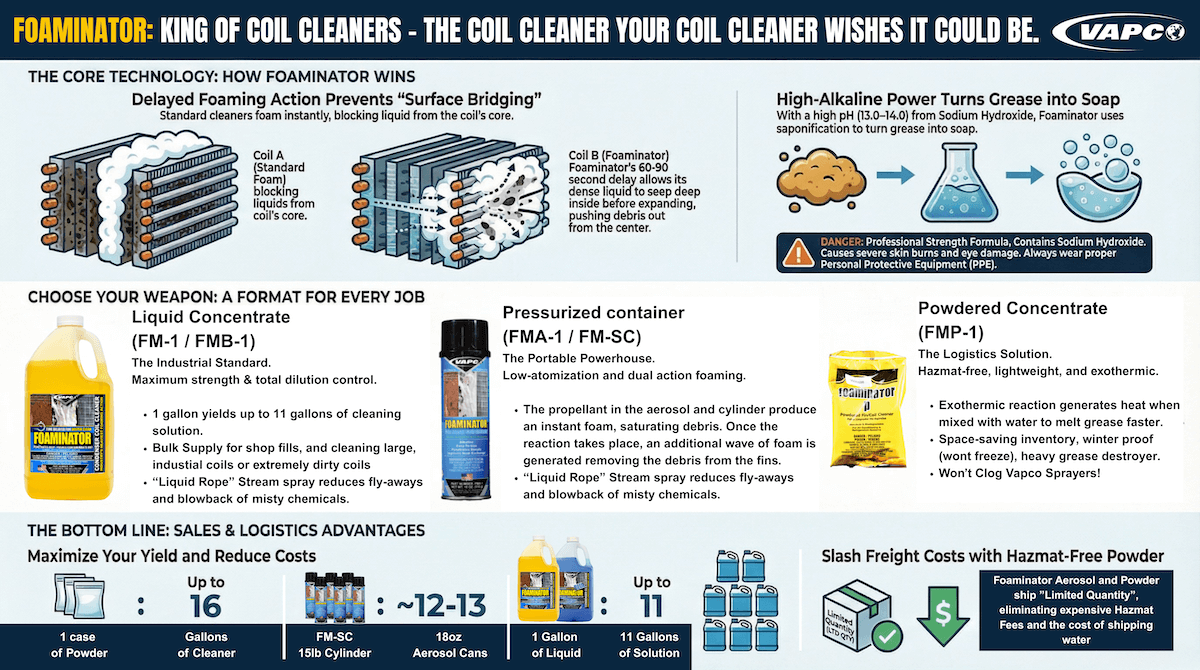

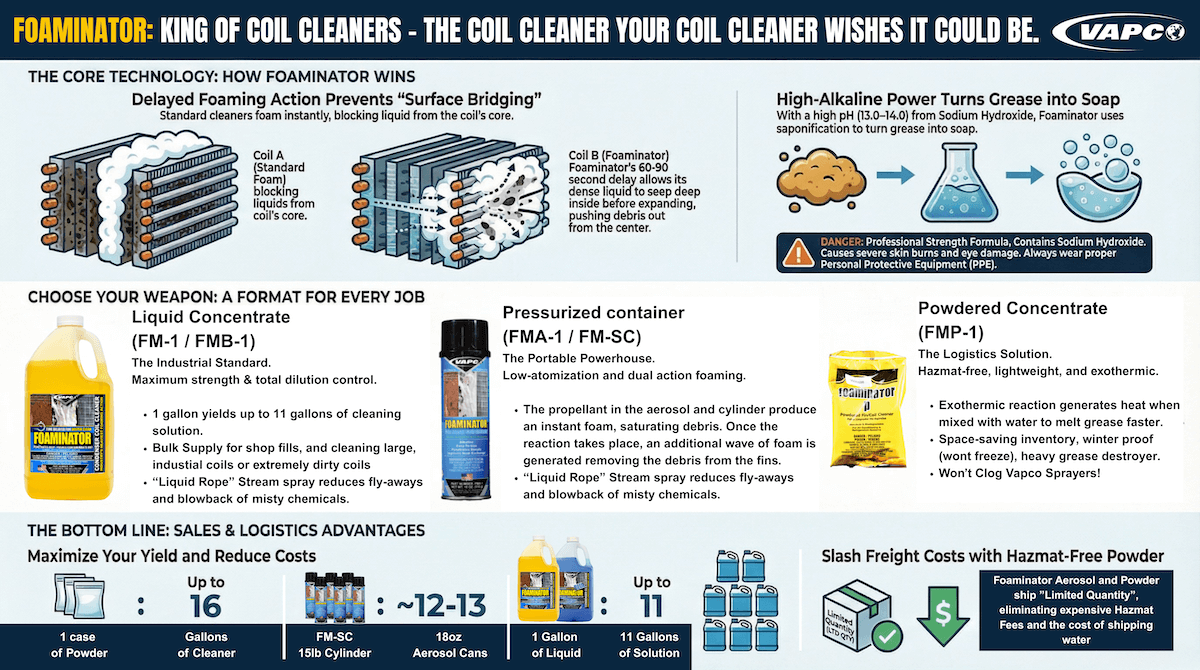

Foaminator is recognized as the “Undisputed King” of coil cleaners because it solves the industry’s biggest problem: Surface Bridging. Standard foaming cleaners expand instantly upon contact, creating a wall of foam that blocks the liquid from reaching the center of the coil. Foaminator utilizes a Delayed-Foaming action that soaks deep into the coil core before expanding, physically pushing debris out from the inside.

Forget what you know about “old school” powders.

In the past, powdered cleaners were notorious for leaving undissolved crystals that clogged sprayer tips and ruined equipment. Foaminator Powder changes the story. As the industry’s premier powdered condenser coil cleaner, FMP-1 is micro-milled for Rapid Dissolution. It dissolves completely in under 60 seconds with just light agitation. We engineered every particle to be smaller than the filter mesh of a Vapco STW sprayer—guaranteeing a clog-free application.

Manufacturer’s Tech Note: The Exothermic Advantage. Foaminator Powder isn’t just lighter; it’s hotter. Rehydrating the high-alkaline crystals creates an Exothermic Reaction—instantly heating the water in your STW sprayer. This thermal energy, combined with the chemical strength, melts grease and heavy oil faster than pre-mixed liquid cleaners that sit cold in the jug.

The Efficiency Math: 1 Case = 8 to 16 Gallons

Foaminator Powder gives you total control over the dilution without shipping the water weight.

- Heavy Duty (1 Bag = 1 Gallon): Mix one 8oz bag with 1 gallon of water for the full “Industrial Strength” experience. This replicates the standard liquid Foaminator performance for impacted coils and grease.

- Maintenance Duty (1 Bag = 2 Gallons): For standard seasonal cleaning, one bag treats 2 gallons of water, doubling your yield to 16 gallons per case while still providing effective foaming action.

| KEY FEATURE / SPECIFICATION |

TRADE BENEFIT / RESULT |

| Exothermic Heat Generation |

Grease Melting Power: The hydration process generates immediate heat, warming the solution to cut through grease and oil faster than cold liquid cleaners. |

| Hazmat-Free Shipping |

Lower Landed Cost: Ships as standard freight (Limited Quantity). No expensive Hazmat fees, no leaking jugs, and no complex shipping restrictions. |

| Time-Delayed Action (60-90s) |

Deep Core Cleaning: Prevents “surface bridging.” The solution soaks into the center of the coil before expanding, pushing debris out from the inside rather than just washing the face. |

| Sodium Hydroxide Base (pH >13) |

Grease Saponification: Turns heavy cooking grease and oils into soap on contact, making them water-soluble and easy to rinse away. |

| 100% Active Chemistry |

Pure Potency: You pay for active chemistry, not shipping water. Contains the same industrial-strength alkaline base and surfactants as the liquid concentrate. |

| Freeze/Thaw Stable |

Winter Safe: Powder cannot freeze and burst. Ideal for service vans in cold climates. |

| Material Compatibility |

Condenser Coils Only: Designed for copper tube/aluminum fin outdoor coils. Not for use on evaporator coils, coated micro-channel coils, or heat exchangers. |

Vapco Field Guide: Performance Matrix

How Foaminator Powder stacks up against real-world contaminants. (★★★ = Best in Class)

| CONTAMINANT |

RATING |

WHY IT WINS |

| Cooking Grease & Oil |

★★★ |

Exothermic Advantage: Heat + Alkalinity saponifies heavy grease instantly. |

| Logistics & Storage |

★★★ |

Space Saver: Stock an entire fleet’s supply on a single shelf. Hazmat-free. |

| Deep Coil Penetration |

★★★ |

Delayed foaming action pushes debris out from the center (just like the liquid). |

| Corrosion & Oxidation |

★★★ |

Brightening Action: Strips white rust and dull oxidation from aluminum fins. |

| Compatibility Warning |

RESTRICTED |

Condenser Coils ONLY. Do not use on Evaporators, Micro-Channel, or Electronic Air Filters. |

Part Number Reference:

| PART NUMBER |

SIZE / PACK |

YIELD POTENTIAL |

| FMP-1 |

8 oz Bag

(8 Bags / Case) |

8 to 16 Gallons: Makes 1 gallon per bag (Heavy Duty) or 2 gallons per bag (Maintenance). |

Recommended Application Tools

Chemically resistant pump-up sprayers designed to handle high-alkaline concentrates like Foaminator.

| PART NUMBER |

CAPACITY |

SERIES FEATURES |

| STW-1 / STW-2 / STW-3 |

1, 2, & 3 Gallon |

Professional Standard: Heavy-duty polyethylene tank with chemically resistant seals and reinforced hose assemblies.

(Note: The 2-Gallon STW-2 is our most popular size for general service work.) |

| STW-2B / STW-3B |

2 & 3 Gallon |

Premium Brass Series: Upgraded with a solid brass spray wand and handle assembly for maximum durability and impact resistance. |

Maintenance Tip: To extend the life of your sprayer seals, always empty the chemical and rinse the tank/hose with water at the end of the day.

3. Other Foaminator Configurations

| Liquid Concentrate |

Foaminator Liquid

The original delayed-expansion formula. Available in gallons, 5s, and drums. |

| Aerosol / Cylinder |

Foaminator Pressurized

Low-atomizing “Liquid Rope” technology. Available in 18 oz cans or 15 lb cylinders. |

Contractors: Please contact your local Vapco distributor for pricing and availability.

Why “Instant Foam” Fails Your Coils

| THE PAIN POINT (Traditional Liquid) |

THE POWDER ADVANTAGE |

“The Freight Bill”

Paying to ship heavy water and plastic jugs across the country. |

“100% Active Concentrate”

One lightweight 8oz bag equals 1 to 2 gallons of finished cleaner. |

“Cold Chemistry”

Liquid cleaners sit cold in the jug, struggling to cut through solidified grease. |

“Exothermic Heat”

Mixing powder creates instant heat. Hot alkaline solution melts grease on contact. |

“Leaking & Freezing”

Jugs burst in winter or leak corrosive fluid in the service van. |

“Solid Stability”

Powders don’t freeze or leak. Shelf-stable and winter-safe. |

FAQs

Frequently Asked Questions: Foaminator Powder (FMP-1)

Application & Performance

Q: Is the powder as strong as the liquid Foaminator?

A: Yes, and potentially better for grease. Once mixed, it is the exact same high-alkaline formula. However, the hydration process creates an Exothermic Reaction (Heat). This hot solution helps melt solidified cooking grease and heavy oils faster than cold liquid cleaners.

Q: Will the powder clog my sprayer tip?

A: No. This is a common fear with “old school” powders, but FMP-1 is different. It is micro-milled for Rapid Dissolution. We engineered the particle size to be smaller than the filter mesh of professional sprayers. As long as you shake it for 10-15 seconds, it dissolves completely.

Q: Why doesn’t it foam immediately when I spray it?

A: This is by design. Just like the liquid version, FMP-1 features a “Delayed Foaming” mechanism. The solution remains liquid for 60 to 90 seconds to soak deep into the center of the coil. Once it reaches the inner rows, the reaction triggers, expanding the foam to push debris out from the inside.

Q: Can I use this on indoor Evaporator Coils?

A: NO. Foaminator is a high-pH alkaline cleaner designed for outdoor condensers only. It produces fumes not suitable for enclosed spaces, and requires heavy rinsing. Use Mongoose (MC-1) or High Tech Evap (HTEC-1) instead.

Mixing & Equipment

Q: Can I use a hose-end sprayer?

A: No. We strictly recommend using a pump-up sprayer (like the Vapco STW series). Hose-end sprayers cannot dissolve the powder effectively or maintain the correct dilution ratio, leading to inconsistent cleaning.

Q: What is the correct mixing ratio?

A: The FMP-1 is pre-measured for simplicity:

- Heavy Duty (1 Bag : 1 Gallon): Use this for restaurant grease, impacted cottonwood, and heavy oxidation.

- Maintenance Duty (1 Bag : 2 Gallons): Use this for standard seasonal cleaning. This doubles your yield to 16 gallons per case.

Q: Why does the tank feel warm when I mix it?

A: That is the Exothermic Reaction. When the alkaline powder hits the water, it releases energy as heat. This is normal and actually helps the cleaning process.

Safety & Compatibility

Q: Is this safe for Micro-Channel coils?

A: NO. Foaminator is a high-pH alkaline cleaner. It can strip the delicate aluminum surfaces of micro-channel coils or coated fins. We strongly recommend using a pH-neutral cleaner like Eco Clean (EC-1) for these applications.

Q: Do I need PPE? It’s just a powder.

A: YES. The powder is highly concentrated Sodium Hydroxide. If dust gets on wet skin or in eyes, it causes severe burns. Always wear goggles and gloves. CRITICAL RULE: Always add Powder to Water (not water to powder) to prevent splashing.

Q: Will it kill the grass around the unit?

A: Yes. High-alkaline runoff can damage vegetation. We recommend flooding the ground beneath the unit with water before and after cleaning to dilute the runoff.

Logistics & Storage

Q: What happens if the bag freezes in my truck?

A: Nothing. That is the biggest advantage of FMP-1. Because it is a dry powder, it cannot freeze, burst, or separate in cold weather. It is perfectly stable in winter conditions.

Q: What is the shelf life?

A: As long as the bag remains sealed and dry, the shelf life is indefinite (5+ years). Moisture is the only enemy.

Q: How do I dispose of the empty bag?

A: The empty bag takes up significantly less landfill space than a plastic jug. Once fully emptied into the sprayer, the packet can be disposed of in standard trash.

SDS & Instructions

⚠️ Professional Use Only

Contains Sodium Hydroxide. Causes severe skin burns and eye damage. POWDER GENERATES HEAT when mixed with water. Always wear goggles and gloves. DO NOT use on Micro-Channel coils.

Field Guide: Contaminant Removal Matrix

Foaminator Powder utilizes a self-heating (exothermic) alkaline blend designed to penetrate deep multi-row coils. The following matrix details performance against common outdoor condenser obstructions.

| TARGET CONTAMINANT |

TYPICAL SOURCE |

ACTION |

PERFORMANCE / WHY IT WORKS |

| Grease & Road Grime |

Kitchen Exhaust / Traffic Film |

Thermal Saponification |

Exothermic Advantage: Mixing the powder generates immediate heat. This thermal energy combines with the high-pH alkalinity to melt grease and convert fats into soap significantly faster than cold liquid cleaners. |

| Cottonwood, Grass, Dirt & Bugs |

Landscaping / Seasonal Debris |

Deep Push-Out |

The “Inside-Out” Clean: Standard foams mat cottonwood onto the surface. Foaminator solution penetrates past the debris, then expands 60-90 seconds later to push the matting out of the coil face. |

| Oxidation & Corrosion |

Environmental Exposure |

Brightening |

Alkaline chemistry strips dull oxide layers and white rust from aluminum fins, restoring the bright metal finish and improving thermal heat transfer. |

| Pollutants & Soot |

Industrial Areas / Rooftops |

Suspension |

Dense foam structure lifts microscopic atmospheric pollutants and carbon soot away from the metal, suspending them for an easy rinse. |

1. System Material Compatibility

| MATERIAL / COMPONENT |

STATUS & PROTOCOL |

| Outdoor Condenser Coils |

✅ RECOMMENDED / RINSE REQUIRED |

| Micro-Channel / Mini-Split Coils (All Aluminum) |

❌ DO NOT USE

High pH will corrode brazed aluminum joints. |

| Indoor Evaporator Coils |

❌ DO NOT USE

Fumes and high-volume rinse requirements make this unsuitable for indoor use. |

| Coated Fins |

⚠️ CAUTION

Alkaline cleaners may strip protective coatings. Use Maintenance Ratio (1:2) or test small area. |

Roof & Surroundings Safety Protocol:

Foaminator’s high-alkaline runoff can damage rubber roof membranes, asphalt, and vegetation. Always ensure all chemical and foam is completely flushed and diluted off the roof/pad during the rinse phase.

*For standard in-place evaporator cleaning, use Mongoose MCC-1 or High Tech Evap (HTEC-1) or Eco Clean (EC-1) in highly sensitive areas.

Directions for Powdered Condenser Coil Cleaner: FMP-1

1. Preparation & Mixing

Step 1: Protect the Surroundings. Pre-soak the ground/roof beneath the unit with water.

Step 2: Shut off power to the HVAC unit.

Step 3: Remove debris (leaves, grass) from the coil exterior.

Mixing Protocol: Always add POWDER TO WATER to prevent splashing. Do not use hose-end sprayers (powder will not dissolve correctly). Use a pump-up sprayer (Vapco STW Series).

| APPLICATION |

RATIO |

INSTRUCTIONS |

| Heavy Duty / Industrial |

1 Bag : 1 Gal |

Fill sprayer with 1 gallon water. Add 1 full bag (8oz).

Yield: 1 Gallon of Industrial Strength Cleaner. |

| Maintenance Duty |

1 Bag : 2 Gal |

Fill sprayer with 2 gallons water. Add 1 full bag (8oz).

Yield: 2 Gallons of Maintenance Cleaner. |

Exothermic Note: Rock the sprayer back and forth for 45-60 seconds. You will feel the tank get warm. This is the Exothermic Reaction (Heat) occurring. This is normal and improves grease cutting. The tank will also begin to self pressurize, do not open until releasing pressure by expelling the product through the hose and wand safely.

2. Application & Cleaning

Leverage the time-delay for maximum penetration.

- Apply Solution:

- Spray the solution onto the coils, starting at the bottom and working your way up.

- Ensure the solution saturates the coil face.

- The Critical Wait (Dwell Time):

- Wait 5 to 8 minutes.

- Observation: You will notice the product does not foam immediately. It is soaking into the center of the coil.

- After the delay, the reaction will trigger, pushing a dense foam outward, carrying the dirt and debris with it.

3. Rinse & Completion

Flush away the saponified grease and debris.

- Rinse Thoroughly:

- Using a hose (low pressure) or pressure washer, rinse the coil from the top down.

- Ensure all foam and chemical residue is removed from the coil and surrounding equipment.

- Restart:

- Restore power to the unit.

🧪 SDS SECTION: POWDER (FMP-1)

1. Identification & Supplier Details

| Product Name |

Foaminator Powder |

| Product Numbers |

FMP-1 |

| Recommended Use |

Alkaline Coil Cleaner (Powder) |

| Emergency Phone |

(800) 255-3924 |

2. Hazard(s) Identification

| GHS Classification |

Skin Corrosion 1A; Eye Damage 1 |

| Signal Word |

DANGER |

| Hazard Statements |

H314: Causes severe skin burns and eye damage. |

| Precautionary Statements |

P260: Do not breathe dusts or mists.

P280: Wear protective gloves/clothing/eye protection.

P303+P361+P353: IF ON SKIN: Take off contaminated clothing. Rinse skin with water.

P305+P351+P338: IF IN EYES: Rinse cautiously with water. Remove contact lenses.

P310: Immediately call a POISON CENTER/doctor. |

3. Composition / Information on Ingredients

| Component Name |

CAS Number |

Concentration |

| Sodium Hydroxide (NaOH) |

1310-73-2 |

75 – 85% |

| Chelating Agent |

64-02-8 |

0.1 – 1% |

4. First-Aid Measures

| Skin Contact |

CORROSIVE. Immediately take off contaminated clothing. Rinse skin with water/shower for at least 15 minutes. |

| Eye Contact |

SEVERE DAMAGE. Rinse cautiously with water for at least 15 minutes. Remove contact lenses. Get medical attention. |

| Inhalation |

Remove person to fresh air. Keep comfortable for breathing. Get medical advice/attention. |

| Ingestion |

Rinse mouth. Do NOT induce vomiting. Get immediate medical attention. |

5. Fire-Fighting Measures

| Specific Hazards |

May be corrosive to metals. Containers may rupture in heat. Hazardous combustion products include alkaline vapors. |

| Suitable Extinguishing Media |

Use dry chemical, foam, or $text{CO}_2$. Do not use water jet. |

| Protective Actions |

Wear NIOSH-approved SCBA with full face piece and full body protective clothing. |

6. Accidental Release Measures

| Personal Precautions |

Do not breathe dust/vapors. Evacuate and isolate unnecessary personnel. Use appropriate PPE. |

| Environmental Precautions |

Prevent entry to sewers and public waters. Avoid release to the environment. |

| Cleanup Methods |

Ventilate the area. Contain any spills with dikes or absorbents. Transfer spilled material to a suitable container for disposal. |

7. Handling & Storage

| Safe Handling |

Do not handle until all safety precautions have been read. Avoid contact with skin/eyes/clothing. Wash hands thoroughly after handling. |

| Storage Conditions |

Store in a dry, cool, well-ventilated place. Protect from sunlight. Store locked up. |

| Incompatible Materials |

Strong acids and aluminum alloys. |

8. Exposure Controls / Personal Protection

| Exposure Limits |

Sodium Hydroxide: OSHA PEL / ACGIH TLV: 2 mg/m³ (Ceiling). |

| Engineering Controls |

Emergency eye wash fountains and safety showers must be available nearby. Ensure adequate ventilation. |

| PPE (Personal Protective Equipment) |

Eyes: Chemical safety goggles.

Skin: Chemical-resistant gloves and protective clothing.

Respiratory: NIOSH-approved SCBA whenever exposure may exceed established OELs. |

9. Physical & Chemical Properties

| Physical State / Appearance |

Solid / Powder |

| Color / Odor |

Off-White / No distinct odor |

| Solubility in Water |

Completely soluble in water |

| pH (Solution) |

N/A (Product is solid; pH applies to solution) |

| Solids Content |

100% |

10. Stability & Reactivity

| Reactivity / Stability |

Reacts with chemically active metals and acids. Stable under normal conditions of use. |

| Conditions to Avoid |

Do not mix with strong acids. Avoid moisture/humidity. |

| Hazardous Decomposition |

Carbon oxide(s), nitrogen oxide(s), sodium oxides, and alkaline vapors (in fire). |

11. Toxicological Information

| Skin/Eye Damage |

Causes severe skin burns and severe irritation, burning, redness, pain to eyes. May cause lens/corneal damage. |

| Acute Toxicity (Oral) |

Glycine, N,N’-1,2-ethanediylbis[N-(carboxymethyl)-, tetrasodium salt: 630-1,260 mg/kg (Rat). |

| Chronic Health Hazards |

Dermatitis may occur due to long-term irritation. |

12. Ecological Information

| Toxicity to Aquatic Life |

Sodium Hydroxide LC50 (Mosquito fish): 125 mg/L (96 hrs); EC50 (Daphnia magna): 40.38 mg/L (48 hrs). |

| Persistence / Mobility |

Product is biodegradable and mobile in soil. Not expected to bioaccumulate. |

13. Disposal Considerations

| Waste Status / RCRA |

This material, as supplied, is a hazardous waste (U.S. EPA 40CFR 261), likely due to corrosivity ($text{D}002$). |

| Disposal Method |

Dispose of contents/container in accordance with all regulations. Do not pierce or burn container. |

14. Transport Information

| Regulation |

UN Number |

Class |

Proper Shipping Name |

| DOT (US) |

UN3262 |

8 (Corrosive) |

Corrosive solid, basic, inorganic, n.o.s. (Packing Group: I) |

15. Regulatory Information

| Right To Know Components |

Sodium Hydroxide is listed on MA, NJ, and PA Right To Know Lists. |

| TSCA Inventory |

Sodium Hydroxide and related components are listed. |

16. Other Information

| Preparation |

Prepared by: Jessica Wilson

Date prepared: 2/14/2025 |

| Disclaimer Summary |

Information is accurate to the best of our knowledge, but no assumption of liability is made for accuracy or completeness. Final determination of suitability is the sole responsibility of the user. |

Specs & Logistics

🛠️ FMP-1 TECHNICAL DATA REPORT – DOWNLOAD

1. Physical & Chemical Properties

| Base Chemistry |

Sodium Hydroxide (75-85%) with Proprietary Surfactants |

| pH Level (In Solution) |

> 13.0 (Highly Alkaline) |

| Reaction Type |

Exothermic (Generates heat upon hydration) |

| Dissolution Rate |

Rapid (Micro-milled to dissolve in under 60 seconds) |

| VOC Content |

Zero VOC / Biodegradable |

| Solubility |

100% Soluble in Water |

| Appearance |

Off-White Powder |

| Shelf Life |

Indefinite (Must remain sealed and dry) |

| Freeze/Thaw Stability |

**Perfectly Stable** (Powder cannot freeze or burst container) |

2. UN & DOT Shipping Classification

Powder (FMP-1)

| Shipping Name: |

Corrosive Solid, Basic, Inorganic, N.O.S. |

| UN Number: |

UN3262 |

| Hazard Class: |

8 (Corrosive) |

| Ltd Qty (LTD QTY): |

YES (Ships Ground Hazmat-Free) |

3. Master Shipping & Dimensions Guide

| ITEM |

INDIVIDUAL UNIT |

QTY / CASE |

CASE SPECS |

PALLET CONFIGURATION |

CODE |

| Part # |

Wt (lbs) |

H (in) |

W (in) |

L (in) |

Units |

Wt (lbs) |

H (in) |

W (in) |

L (in) |

Cases/Pallet |

Total Units |

Wt (lbs) |

H (in) |

W (in) |

L (in) |

UPC |

FMP-1

(8 oz Bag) |

0.5 |

[ ] |

[ ] |

[ ] |

8 |

4.5 |

[ ] |

[ ] |

[ ] |

[ ] |

[ ] |

[ ] |

[ ] |

40 |

48 |

[ ] |

Harmonized Tariff Code (HTS): 3402.20.5100 (Cleaning Preparations)

NMFC Code: 48580 (Compounds, Cleaning, Dry) – Class 55

Resources

🔍 Product Family: Liquid, Aerosol & Powder Formats (Click to Enlarge)